High-speed packaged multilayer co-extrusion, thermal forming and drawing bottom film and production process

A multi-layer co-extrusion and production process technology, which is applied in the field of high-speed packaging multi-layer co-extrusion thermoforming stretch bottom film and production process, can solve the problems of inability to meet the operation requirements, reduce the glass transition temperature of nylon materials, and low material crystallinity and other problems, to achieve the effect of excellent low-temperature heat-sealing performance and anti-pollution heat-sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

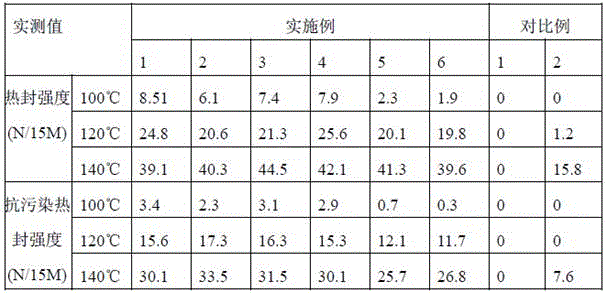

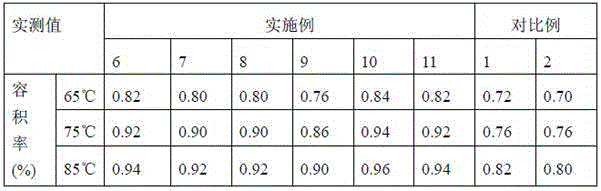

Examples

Embodiment 1

[0022] The high-speed packaging multi-layer co-extrusion thermoforming stretch base film of Example 1 includes a surface layer, a barrier core layer and a heat-sealing layer. Specifically, the film structure of Example 1 is PP / PA / POP;

Embodiment 2

[0024] The difference between embodiment 2 and embodiment 1 is the heat seal layer, and the film structure of embodiment 2 is PP / PA / Surlyn;

Embodiment 3

[0026] The difference between Example 3 and Example 1 lies in the barrier core layer, and the film structure of Example 3 is PP / PA / EVOH / PA / POP;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com