An Adsorbent Material for Efficiently Removing Phosphorus from Water

An adsorption material and water removal technology, applied in the direction of adsorption water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as not being put into use have achieved the effect of low price, wide application range and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

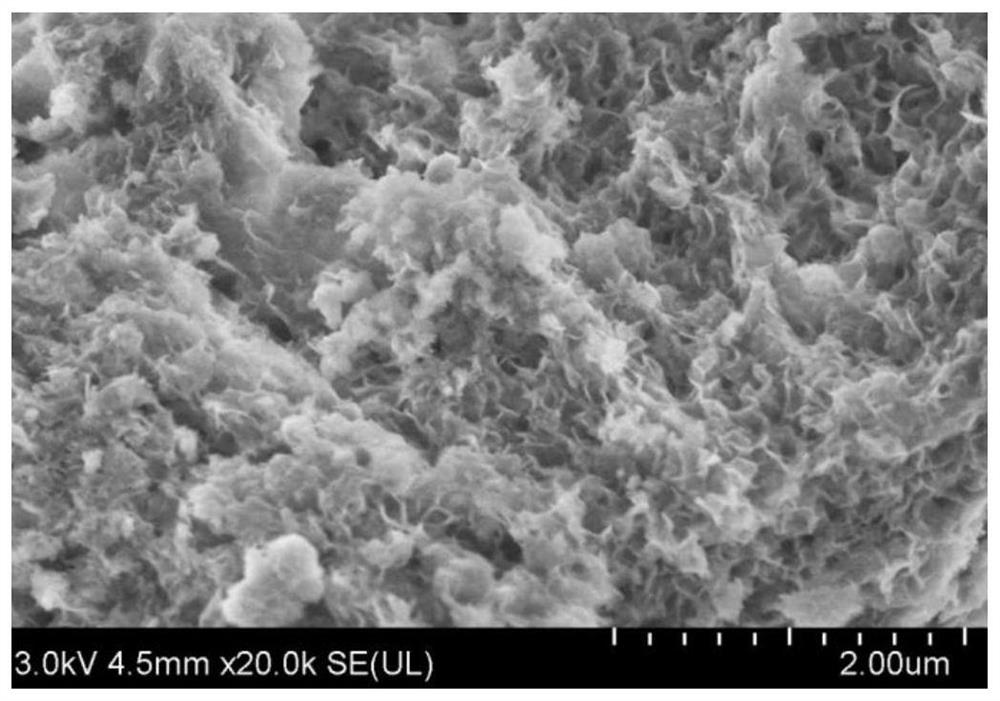

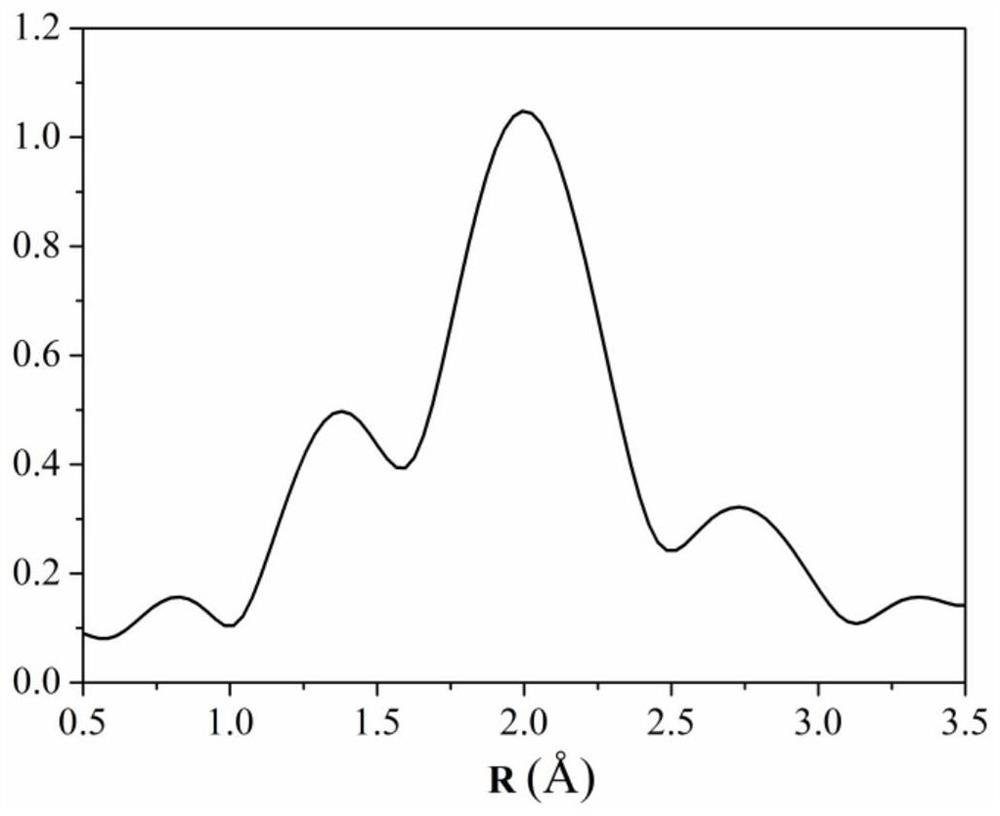

[0021] Weigh 4g of lanthanum chloride and 13g of aluminum chloride into a 1L Erlenmeyer flask (1); add 200mL of deionized water, and stir for 10min in a water bath at 60°C to dissolve completely (2); add 2mol L -1 Stop adding the sodium hydroxide solution until the pH is 9 (3); keep the system temperature at 60°C and continue heating for 10 hours (4); wash the product with about 1L deionized water for 3 to 4 times, centrifuge to remove the supernatant, and freeze Drying (5); Grinding to obtain the powdery product of phosphorus removal adsorbent (6). Among them, the content of lanthanum hydroxide accounts for 18% of the dry weight of the product, the content of aluminum hydroxide accounts for 77% of the dry weight of the product; the content of lanthanum aluminate accounts for 5% of the dry weight of the product; the applicable pH range is 4-10.

[0022] In the obtained powder: containing La%=13%; containing Al%=27%.

Embodiment 2

[0024] Weigh 4g of lanthanum chloride and 20g of aluminum chloride into a 1L Erlenmeyer flask (1); repeat steps (2) to (6) in Example 1 for the rest of the preparation process. Among them, the content of lanthanum hydroxide accounts for 14% of the dry weight of the product, the content of aluminum hydroxide accounts for 85% of the dry weight of the product; the content of lanthanum aluminate accounts for 1% of the dry weight of the product; the applicable pH range is 4-10.

[0025] In the obtained powder: containing La%=10%; containing Al%=29%.

Embodiment 3

[0027] Weigh 4g of lanthanum chloride and 27g of aluminum chloride into a 1L Erlenmeyer flask (1); repeat steps (2) to (6) in Example 1 for the rest of the preparation process. Among them, the content of lanthanum hydroxide accounts for 11% of the dry weight of the product, the content of aluminum hydroxide accounts for 86% of the dry weight of the product; the content of lanthanum aluminate accounts for 3% of the dry weight of the product; the applicable pH range is 4-10.

[0028] In the obtained powder: containing La%=8%; containing Al%=30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com