A kind of preparation method of pps superfine fiber acupuncture filter bag

A superfine fiber, acupuncture technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of single use, no filter bag preparation method, no flame retardant filter bag, antistatic and high temperature resistance, etc. To achieve the effect of strong practicability, easy mechanized operation and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

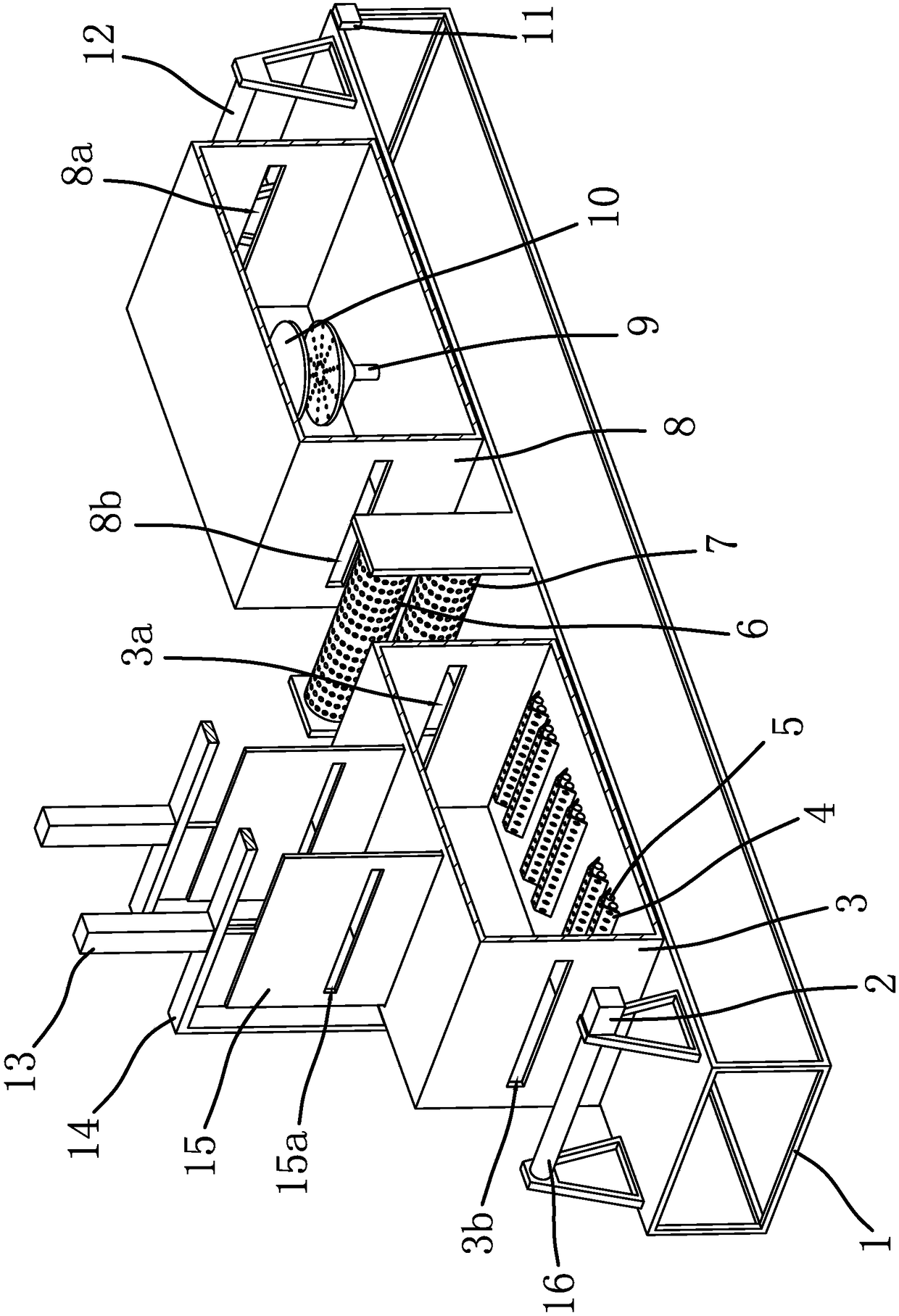

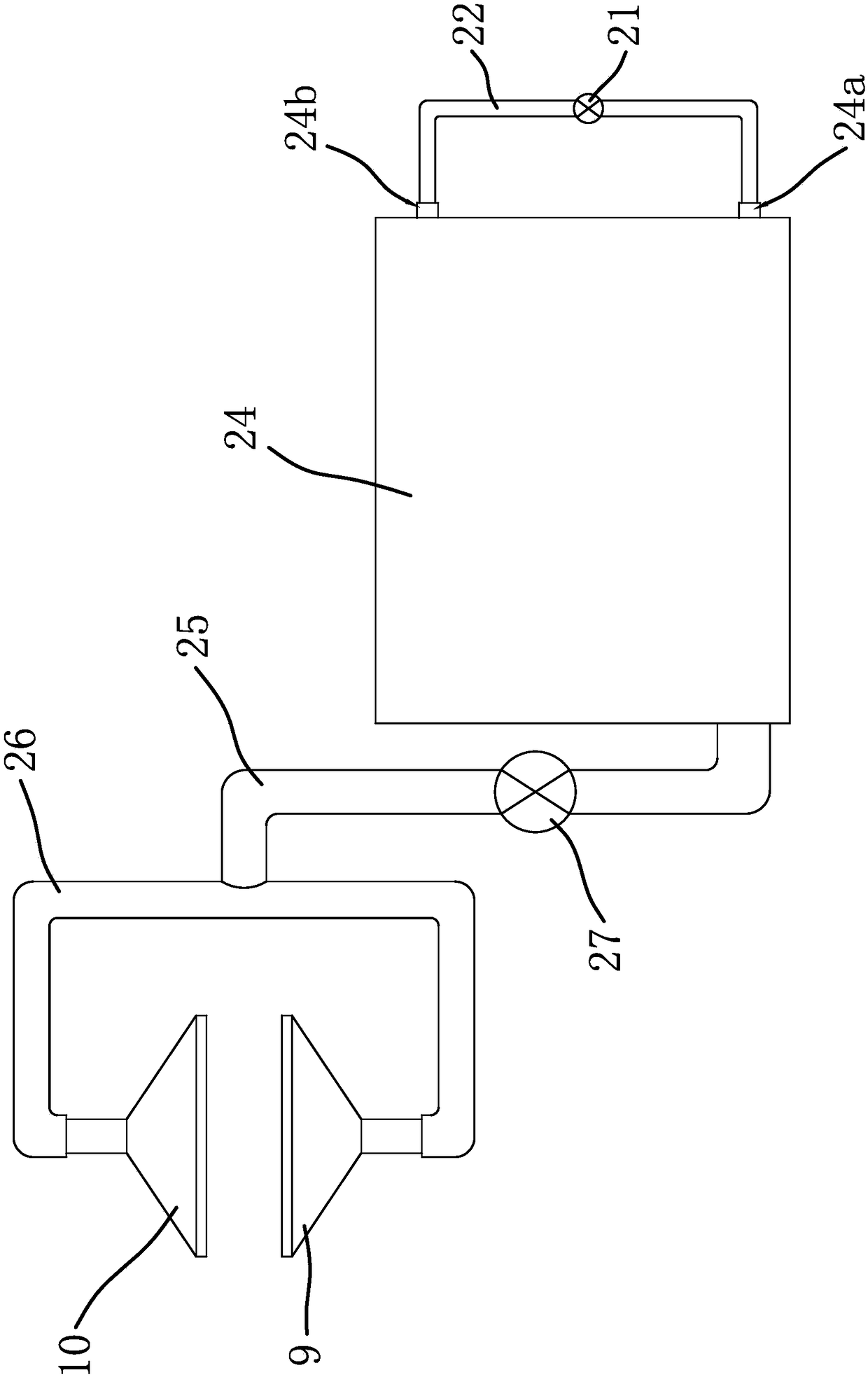

Method used

Image

Examples

Embodiment 1

[0043] This PPS microfiber needle-punched filter bag includes a bag body, a bag head and a bag bottom. One end of the bag body is fixed to the bag head, and the other end of the bag body is fixed to the bottom of the bag. The protective layer is fixed on both sides of the base cloth layer, and the protective layer is composed of the following components in parts by weight: 70-80 parts of polytetrafluoroethylene concentrated dispersion, 1-2 parts of coupling agent, 10-15 parts of epoxy phenolic resin 1-2 parts of thermosetting acrylic resin, 0.5-0.8 parts of benzyl silicone oil, 3-6 parts of magnesium oxide, 3-6 parts of zinc oxide, 1-2 parts of antistatic agent and 30-60 parts of deionized water; After this component, since the main raw material of the protective layer is polytetrafluoroethylene concentrated dispersion, an appropriate amount of coupling agent, epoxy phenolic resin, thermosetting acrylic resin, benzyl silicone oil, magnesium oxide, zinc oxide, Antistatic agent ...

Embodiment 2

[0047] This PPS microfiber needle-punched filter bag includes a bag body, a bag head and a bag bottom. One end of the bag body is fixed to the bag head, and the other end of the bag body is fixed to the bottom of the bag. The protective layer is fixed on both sides of the base cloth layer, and the protective layer is composed of the following components in parts by weight: 70-80 parts of polytetrafluoroethylene concentrated dispersion, 1-2 parts of coupling agent, 10-15 parts of epoxy phenolic resin 1-2 parts of thermosetting acrylic resin, 0.5-0.8 parts of benzyl silicone oil, 3-6 parts of magnesium oxide, 3-6 parts of zinc oxide, 1-2 parts of antistatic agent and 30-60 parts of deionized water; After this component, since the main raw material of the protective layer is polytetrafluoroethylene concentrated dispersion, an appropriate amount of coupling agent, epoxy phenolic resin, thermosetting acrylic resin, benzyl silicone oil, magnesium oxide, zinc oxide, Antistatic agent ...

Embodiment 3

[0051] This PPS microfiber needle-punched filter bag includes a bag body, a bag head and a bag bottom. One end of the bag body is fixed to the bag head, and the other end of the bag body is fixed to the bottom of the bag. The protective layer is fixed on both sides of the base cloth layer, and the protective layer is composed of the following components in parts by weight: 70-80 parts of polytetrafluoroethylene concentrated dispersion, 1-2 parts of coupling agent, 10-15 parts of epoxy phenolic resin 1-2 parts of thermosetting acrylic resin, 0.5-0.8 parts of benzyl silicone oil, 3-6 parts of magnesium oxide, 3-6 parts of zinc oxide, 1-2 parts of antistatic agent and 30-60 parts of deionized water; After this component, since the main raw material of the protective layer is polytetrafluoroethylene concentrated dispersion, an appropriate amount of coupling agent, epoxy phenolic resin, thermosetting acrylic resin, benzyl silicone oil, magnesium oxide, zinc oxide, Antistatic agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface density | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

| surface density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com