Inulin rose chewable tablets

A technology of chewable tablets and inulin, which is applied in the field of chewable tablets, can solve problems such as the production and sales of inulin rose chewable tablets that have not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

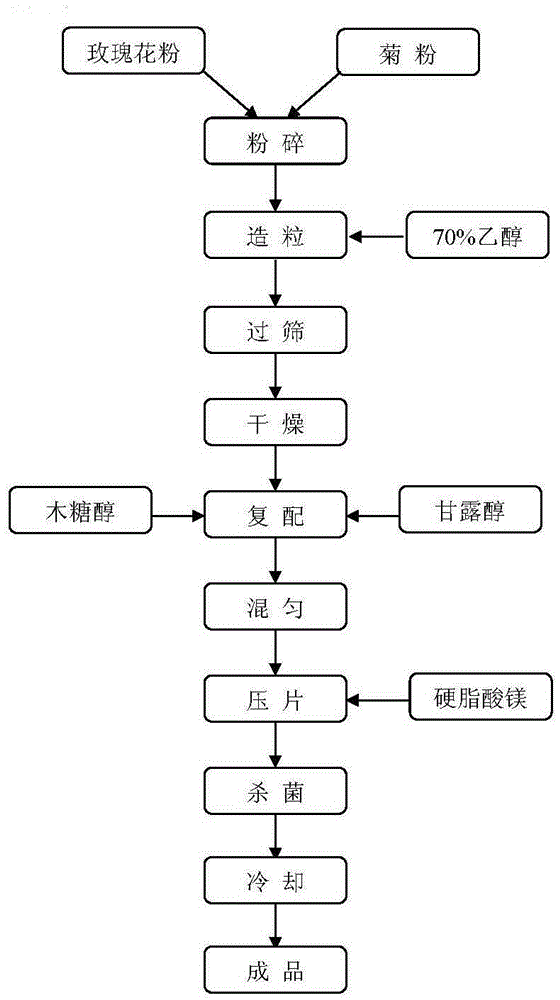

Method used

Image

Examples

Embodiment 1

[0013] Example 1 Weigh 94kg of inulin and 6kg of rose pollen, mix well and pulverize, pass through a 100-mesh sieve to obtain 100kg of uniform powder; spray 8L of ethanol-containing 70% solution on the powder in proportion, then mix and granulate, pass through a 60-mesh sieve to obtain Inulin rose granules. Place the granules in a constant temperature oven and dry at 80°C for 25min~40min until the water content reaches 4%; add 0.8kg of xylitol and 2kg of mannitol to the mixture and mix well, then add 10kg of magnesium stearate After mixing, it is sent to a tablet press for tablet compression, and the finished product is packaged.

Embodiment 2

[0014] Example 2 Weigh 96kg of inulin and 4kg of rose pollen respectively, mix and pulverize, and pass through a 100-mesh sieve to obtain 100kg of uniform powder; spray 8L of a solution containing 70% ethanol on the powder in proportion, then mix and granulate, and pass through a 60-mesh sieve to obtain Inulin rose granules. Put the granules in a constant temperature oven and dry them at 80°C for 25min~40min until the water content reaches 4%; add 0.8kg of xylitol and 2kg of mannitol to the mixture and mix well, then add 10kg of stearic acid After the magnesium is mixed, it is sent to a tablet press for tablet compression, and the finished product is packaged.

Embodiment 3

[0015] Example 3 Weigh 98kg of inulin and 2kg of rose pollen respectively, mix them evenly and pulverize them, and pass through a 100-mesh sieve to obtain 100kg of uniform powder; spray 8L of 70% ethanol solution on the powder in proportion, then mix and granulate, and pass through a 60-mesh sieve to obtain Inulin rose granules. Put the granules in a constant temperature oven and dry them at 80°C for 25min~40min until the water content reaches 4%; add 0.8kg of xylitol and 2kg of mannitol to the mixture and mix well, then add 10kg of stearic acid After the magnesium is mixed, it is sent to the tablet press for tablet compression, and the finished product is packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com