Purifying processing technology for uncooked oysters

A processing technology, a technology for eating oysters, which is applied in the field of purification and processing technology for eating raw oysters, can solve the problems of insufficient vigor of shellfish, backward purification of shellfish, and lack of competitiveness, etc., and achieve a good market prospect, high freshness, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

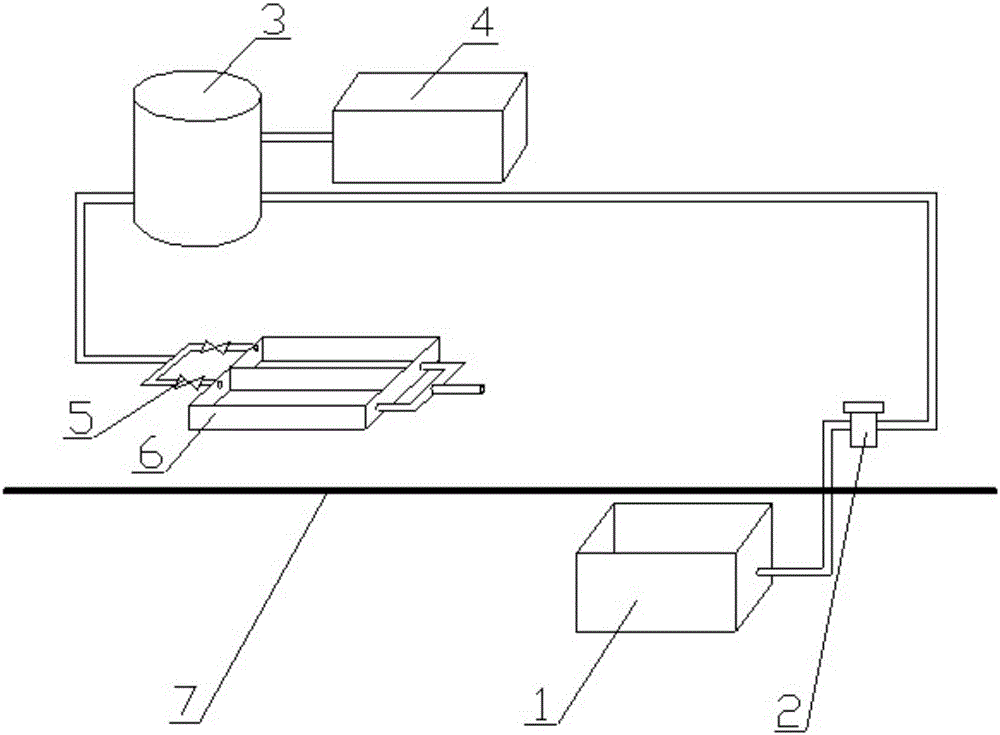

Image

Examples

Embodiment 1

[0033] According to the technical requirements of the present invention, in a 2 ton / time-scale shellfish purification pilot plant built in Tuandao, Qingdao, Shandong, 20Kg each of pleated oysters, Dalian Bay oysters, Pacific oysters, and dense scale oysters were taken, and they were temporarily raised for 7 days. , and then infect the norovirus-positive stool samples and coliform culture fluid respectively, after 48hr purification, the coliform group was detected by GB4789.3-94, and the norovirus was detected by SN / T2626-2010, and the changes before and after purification were compared , the results showed that the content of coliform bacteria increased by 10 4 -10 5 The MPN / 100g shell meat dropped to 42, and no sediment was detected.

Embodiment 2

[0035] According to the technical requirements of the present invention, in a 5 ton / time scale oyster purification factory built in Zhanjiang, Guangdong, 50Kg of oysters near the river were taken, and after 2 days of temporary cultivation, they were infected with norovirus-positive feces samples and coliform bacteria respectively. The culture medium was purified for 48 hours. The coliform bacteria were detected by GB4789.3-94 and the norovirus was detected by SN / T2626-2010. Compared with the changes before and after purification, the results showed that the coliform bacteria content increased from 2.4×10 5 The MPN / 100g shell meat dropped to 42, and no sediment was detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com