Mould thermal treatment workshop dynamic batch scheduling method

A batch-scheduling and dynamic technology, applied in the field of dynamic batch-scheduling in mold heat treatment workshops, can solve problems such as slowing down of computing speed and increasing of computing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

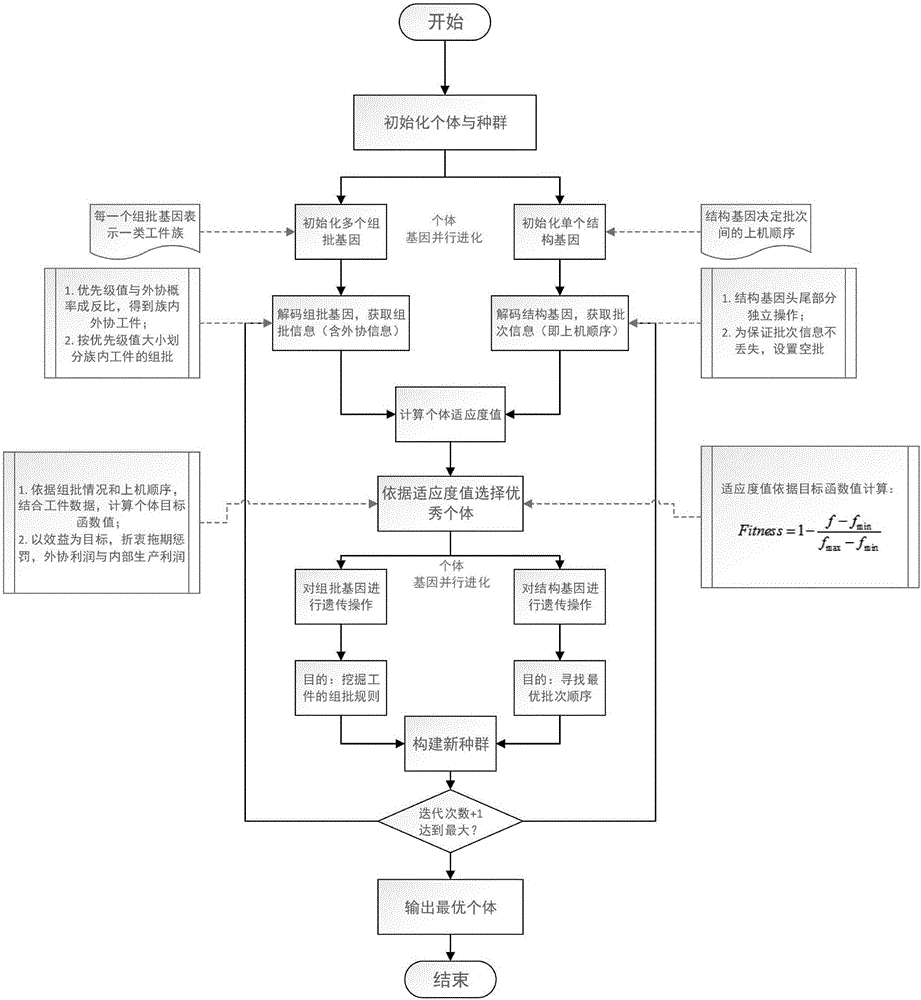

[0032] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0033] See attached figure 1 As shown, a dynamic batch scheduling method in a mold heat treatment workshop of the present invention comprises the following steps:

[0034] S1. Obtain the properties of workpieces that arrive dynamically at the mold heat treatment workshop through the ERP system{T r , T p , T d ,N,α,P in ,P out}, where T r is the arrival time, T p is the processing time, T d is the processing time margin, N is the total number of workpieces in this workpiece family, a is the penalty coefficient for workpiece delay, P in is the internal production cost of the workpiece, P out for outsourcing costs.

[0035] S2. Design the batch gene and structural gene in the gene expression programming algorithm, wherein the batch gene represents a kind of workpiece family, and the structural gene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com