Dedusting equipment

A technology of equipment and filter cartridges, which is applied in the field of dust removal equipment, can solve the problems of reduced fan efficiency, high wind pressure in local cavities, and high wind noise, etc., and achieve the effect of improving filtration efficiency, good noise reduction effect, and good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

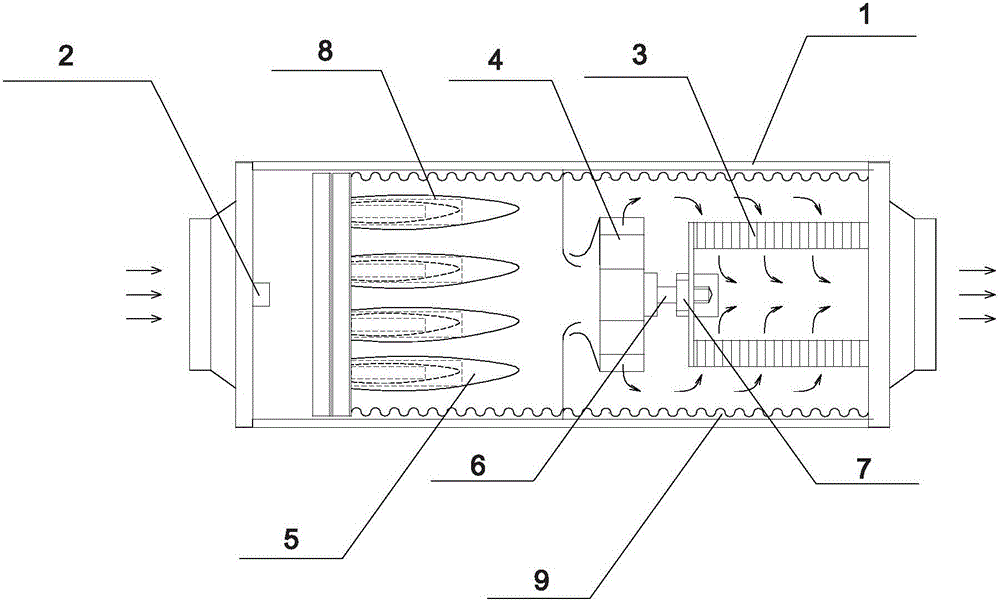

[0028] like figure 1 , figure 2 As shown, a dust removal device includes a square cylindrical box body 1, the axis of the box body 1 is horizontal, the inlet end of the box body 1 is provided with a negative ion generator 2, and the outlet end of the box body 1 is provided with a filter with a closed end. Cartridge 3, the wall of the filter cartridge 3 is surrounded by a filter screen, the end face of the opening end of the filter cartridge 3 is sealed and bonded to the end wall of the outlet end of the box body 1, and the opening of the filter cartridge 3 is connected to the outlet of the box body 1, and the negative ions An intermediate filter device is provided between the generator 2 and the filter cartridge 3, and a fan 4 is fixed between the intermediate filter device and the filter cartridge 3, and the fan 4 is fixed on a fan fixing frame arranged along the cross section of the box body 1. The axes of the filter cartridge 3 , the fan 4 and the box body 1 are coinciden...

Embodiment 2

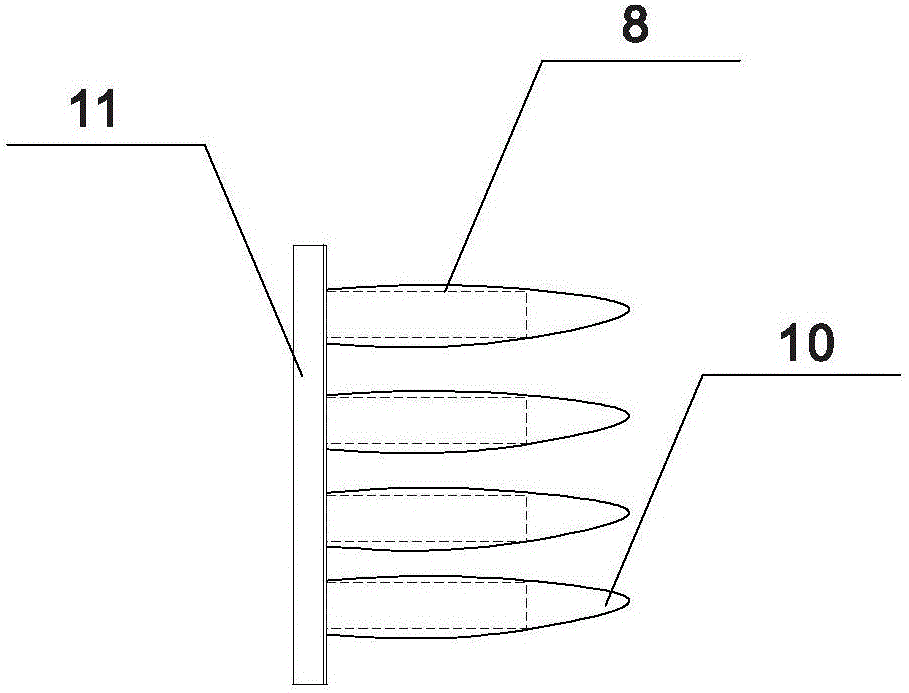

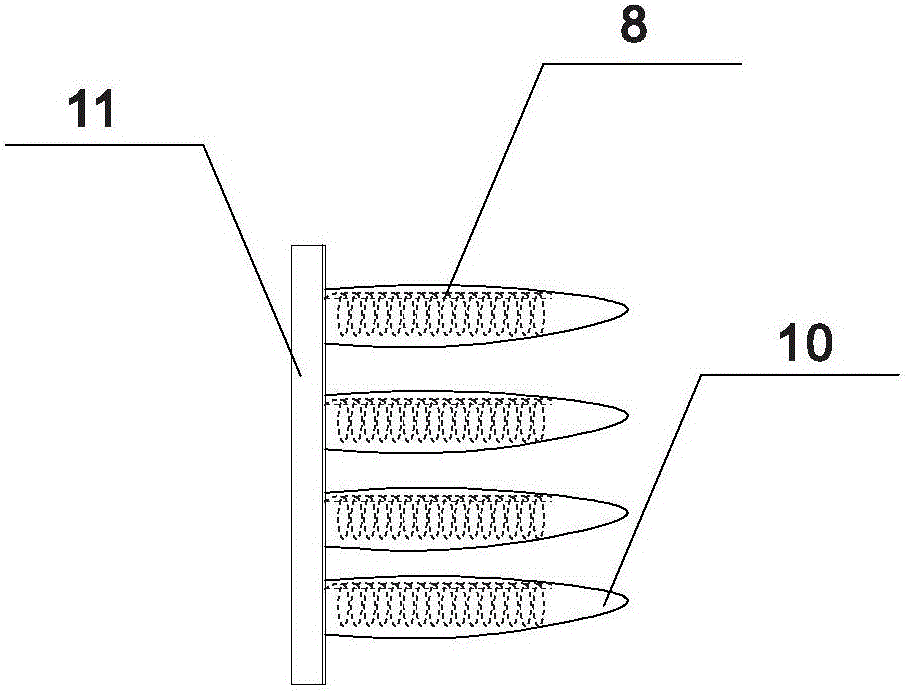

[0031] like image 3 As shown, the inside of the bag filter of the bag filter 5 is provided with an expansion support frame 8, which is a deformable helical structure and is made of elastic strip material, which is a spring steel wire in this embodiment. The upper edge of the air hole of the bag filter 5 filter screen support is also fixed with an axially protruding pick rod, and the pick rod penetrates into the center hole of the spiral coil of the expansion support frame 8, which can prevent the expansion support frame 8 from being damaged by the bag-shaped filter screen. The radial bending is generated due to the gravity falling, so as to maintain the shape and movement function of the expansion support frame 8. All the other are with embodiment 1.

[0032] The expansion support frame 8 can not only expand the bag filter 5, but also has a buffering effect like a spring. When the wind speed in the box 1 is unstable, the bag filter 5 can be used to disturb the flow in the ai...

Embodiment 3

[0034] The intermediate filtering device is a finishing structure, and the expansion support frame 8 is cylindrical. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com