High-stability combined latticed column and processing technology thereof

A highly stable and qualified technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of affecting safety, poor support capacity and bearing capacity, and small included angle, so as to improve the stability of installation and support performance , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

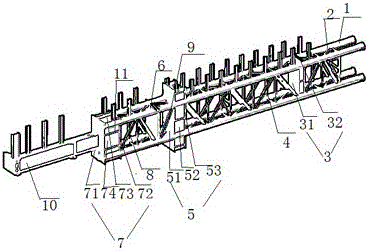

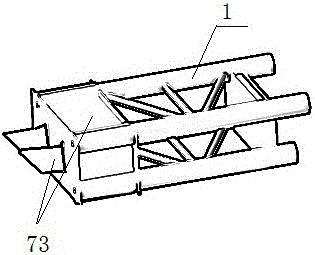

[0057] Such as figure 1 and figure 2 A high-stability composite lattice column shown includes: a first segment, a second segment and a third segment, and the second segment and the third segment are sequentially arranged on the first segment One end, wherein, the first segment and the second segment are respectively equipped with a steel pipe column 1 for welding the first segment and the second segment, a reinforcing tube 2, a small closing piece 3, a steel tube web 4, and a second column Inter-steel platform 5, the second small closing piece 6, the steel platform 7 between the columns on the fourth floor, web bars 8, embedded web bars 9,

[0058] Wind-resistant column 10 and reinforcing plate 11;

[0059] The relationship between the above components is as follows:

[0060] The steel pipe columns 1 used for welding the first segment are connected by reinforcing pipes 2 to form the first crane beam plane, and the upper and lower first crane beam planes are positioned and ...

Embodiment 2

[0067] The structure of the high-stability composite lattice column in the processing technology of the high-stability composite lattice column described in this embodiment is the same as that in Embodiment 1.

[0068] Such as figure 1 and figure 2 A high-stability composite lattice column shown includes: a first segment, a second segment and a third segment, and the second segment and the third segment are sequentially arranged on the first segment One end, wherein, the first segment and the second segment are respectively equipped with a steel pipe column 1 for welding the first segment and the second segment, a reinforcing tube 2, a small closing piece 3, a steel tube web 4, and a second column Inter-steel platform 5, the second small closing piece 6, the steel platform 7 between the columns on the fourth floor, web bars 8, embedded web bars 9,

[0069] Wind-resistant column 10 and reinforcing plate 11;

[0070] The relationship between the above components is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com