In-situ preparation method of composite magnetic water treatment material

An in-situ preparation and magnetic material technology, applied in mining wastewater treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem that the treatment effect is difficult to meet the actual needs of oilfield water treatment, and achieve Efficient water treatment, strong dispersibility, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

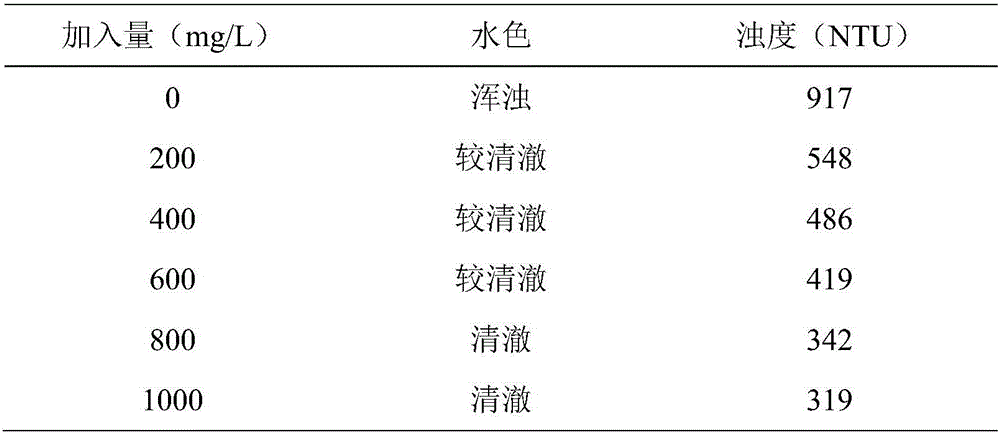

Examples

Embodiment 1

[0019] Step 1: In situ deposition to prepare organically supported Fe 3 o 4 magnetic aggregates

[0020] Measure 55ml of deionized water into the reactor, connect the sealed ventilation device, and bubble nitrogen into the deionized water for 30min. Weigh FeSO 4 ·7H 2 O powder 2.92g, C 17 h 35 Add 0.15 g of COONa (sodium octadecanoate) powder into the reactor, turn on the heating at 75°C, adjust the mechanical stirrer, keep the nitrogen flow continuously flowing, and stir and mix the system at a speed of 400 rpm for 15 minutes. Weigh 1.0g of NaOH powder, NaNO 3 1.7g of powder was dissolved in 20ml of deionized water, and the mixed solution was added to a 25ml constant pressure funnel and connected to the reactor. The heating temperature was raised to 85°C, the stirrer speed was increased to 700 rpm, and the NaNO 3 -NaOH mixed solution was added dropwise to the reaction system, reacted for 0.5h, and the reaction system gradually turned black.

[0021] Step 2: Organic l...

Embodiment 2

[0024] Step 1: In situ deposition to prepare organically supported Fe 3 o 4 magnetic aggregates

[0025] Measure 55ml of deionized water into the reactor, connect the sealed ventilation device, and bubble nitrogen into the deionized water for 30min. Weigh FeCl 3 ·6H 2 O powder 2.84g, C 17 h 33 Add 0.30 g of COONa (sodium octadecenoate) powder into the reactor, turn on the heating at 65°C, adjust the mechanical stirrer, keep the nitrogen flow continuously flowing, and stir and mix the system at a speed of 400 rpm for 15 minutes. Weigh 1.0g of NaOH powder, NaNO 3 1.7g of powder was dissolved in 20ml of deionized water, and the mixed solution was added to a 25ml constant pressure funnel and connected to the reactor. The heating temperature was increased to 80°C, the stirrer speed was increased to 700 rpm, and the NaNO 3 -NaOH mixed solution was added dropwise to the reaction system, reacted for 0.5h, and the reaction system gradually turned black.

[0026] Step 2: Organi...

Embodiment 3

[0029] Step 1: In situ deposition to prepare organically supported Fe 3 o 4 magnetic aggregates

[0030] Measure 50ml of deionized water into the reactor, connect the sealed ventilation device, and bubble nitrogen into the deionized water for 30min. Weigh FeCl 3 ·6H 2 O powder 2.84g, C 17 h 35 Add 0.15 g of COONa (sodium octadecanoate) powder into the reactor, turn on the heating at 75°C, adjust the mechanical stirrer, keep the nitrogen flow continuously flowing, and stir and mix the system at a speed of 400 rpm for 10 min. Weigh 1.0g of NaOH powder, NaNO 3 1.7g of powder was dissolved in 20ml of deionized water, and the mixed solution was added to a 25ml constant pressure funnel and connected to the reactor. The heating temperature was raised to 85°C, the stirrer speed was increased to 700 rpm, and the NaNO 3-NaOH mixed solution was added dropwise to the reaction system, reacted for 0.5h, and the reaction system gradually turned black.

[0031] Step 2: Organic load F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com