Automatic Lubricating Device for Vertical Screw Conveyor

A vertical screw, automatic lubrication technology, used in conveyor objects, liquid distribution, conveying or transfer devices, cleaning devices, etc., can solve the problems of low degree of automation, low lubrication efficiency, and reduced running speed, and achieve high degree of automation, The effect of convenient oil injection and stable oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

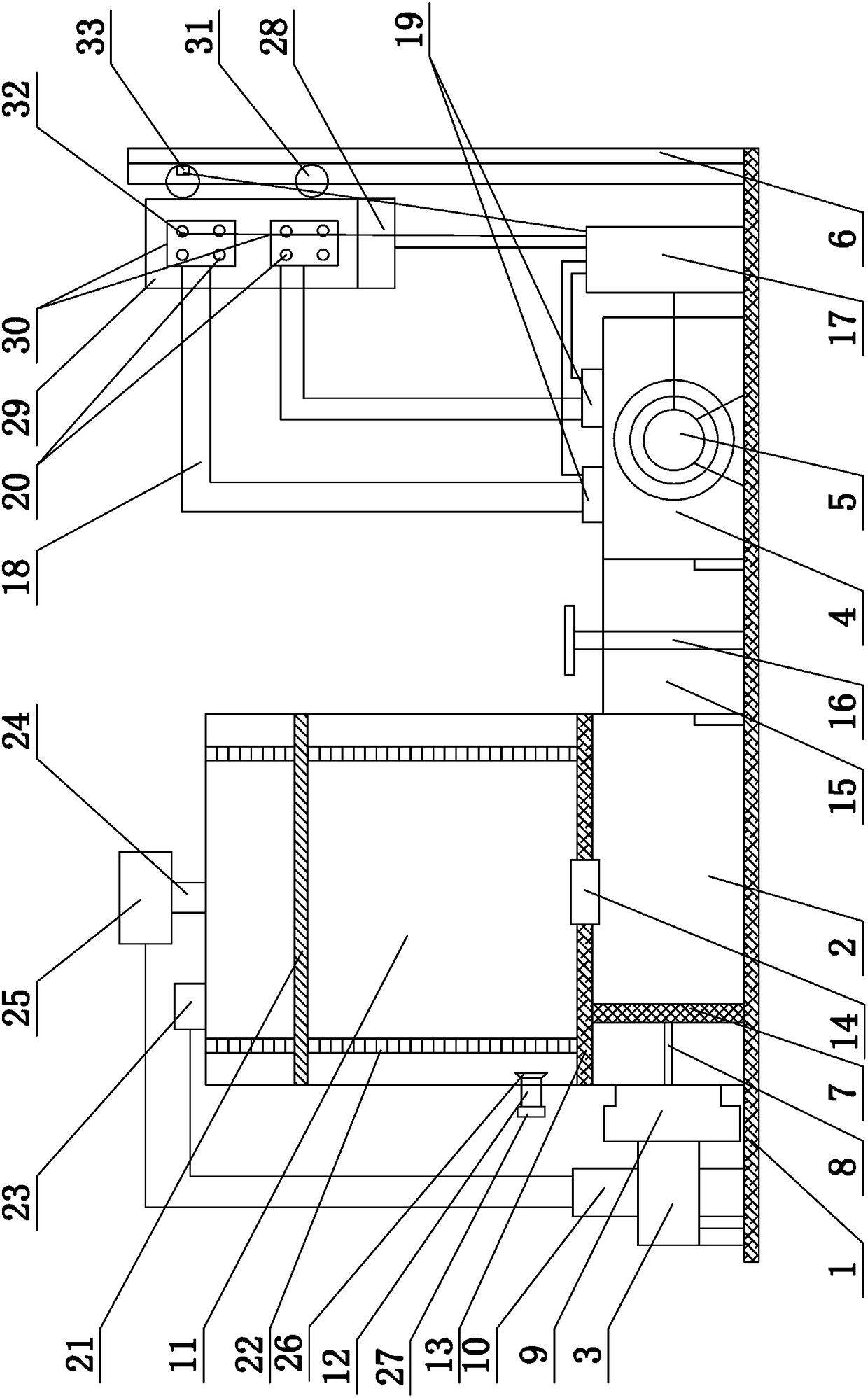

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, an automatic lubricating device for a vertical screw conveyor includes a bottom plate 1, which is a shock-absorbing and noise-absorbing layer. The plug motor 5 and the rolling support plate 6, the oil outlet cylinder body 2 is provided with an oil outlet piston 7, the oil outlet piston 7 is connected to the rotating mechanism 9 through the oil outlet piston rod 8, the rotation mechanism 9 is connected to the output shaft of the oil outlet motor 3, and the oil outlet The motor 3 is connected to the controller I10 through a control line. The oil outlet cylinder 2 is provided with an oil inlet and an oil outlet, and an oil barrel 11 is arranged on the top of the oil outlet cylinder 2. The oil barrel 11 is a transparent oil barrel 11. Lubricating oil is stored, and a moving plate 21 is suspended on the liquid surface of the lubrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com