Polishing separator for oil switch

A separation machine and switch technology, which is applied in the field of parts processing, can solve the problems of difficult selection of processed parts, inability to directly separate, low processing efficiency, etc., and achieve the effect of easy access, reduced difficulty, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

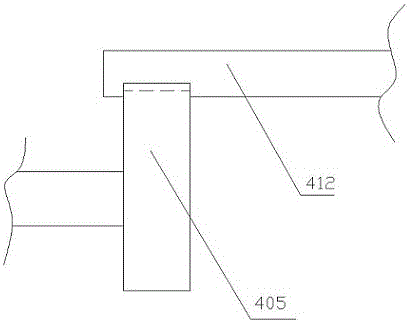

[0016] The reference signs in the accompanying drawings of the description include: grinding machine table 10, material inlet and outlet 101, vibration motor 20, vibration device 201, base 30, drive motor 40, power output shaft 401, rotating shaft 402, teeth 412, roller mechanism 403 , the receiving frame 404 , the first through hole 414 , the transmission gear 405 , and the abrasive material 50 .

[0017] The embodiment is basically as attached figure 1 And attached figure 2 Shown: a kind of oil switch grinding separator, comprises grinder platform 10, vibrating device 201, vibrating motor 20, base 30 and abrasive material 50, is provided with inlet and outlet 101 on the side of cylindrical grinder platform 10, feed inlet And the discharge port is set as a discharge port 101, in order to simplify the disassembly process of the housing frame 404; the side of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com