Pressure cooker cover grinding machine

A grinding machine and pot cover technology, which is applied to the parts of grinding machine tools, grinding machines, grinding workpiece supports, etc., can solve the problems of laborious work, poor roundness, etc., and achieve the effect of convenience, comfort and good roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

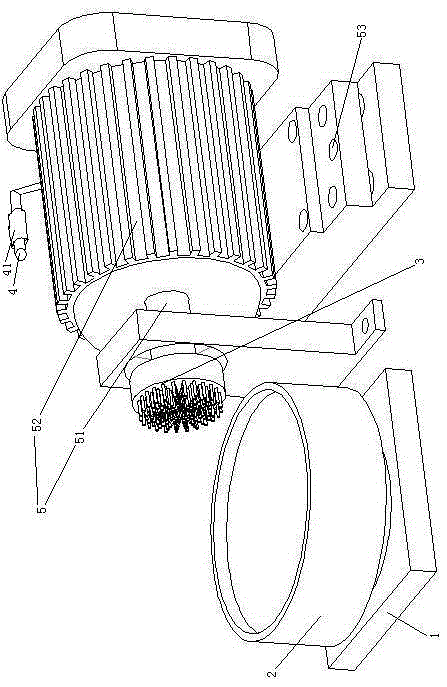

[0022] Example 1, see figure 1 , a pressure cooker lid grinder, including a base 1 and a motor 5. A support bowl 2 is rotatably connected to the base 1 . The motor 5 includes a motor shaft 51 and a motor case 52 . The left end of the motor shaft 51 protrudes from the motor housing 52 . The grinding head 3 is connected to the left end of the motor shaft 51 . The sanding head 3 is located outside the support bowl 2 . The grinding head 3 is located on the radially outer side of the support bowl 2, that is, outside the cylindrical surface where the outer peripheral surface of the support bowl is located. The motor housing 52 is fixed on the motor mounting frame 53 .

[0023] The motor housing 52 is provided with the handle bar 4 . The outer elastic sleeve of the handle bar 4 is provided with a sleeve 41 .

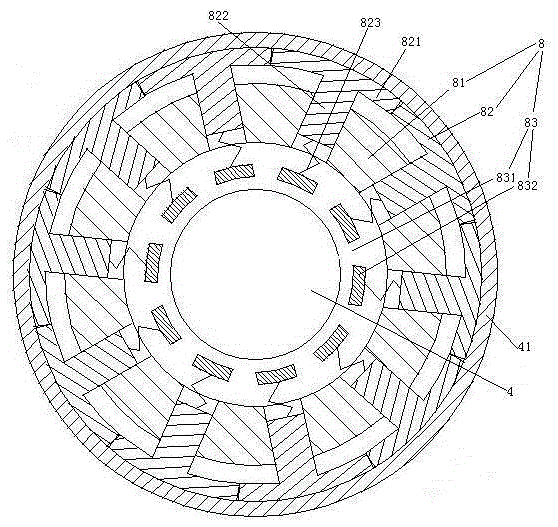

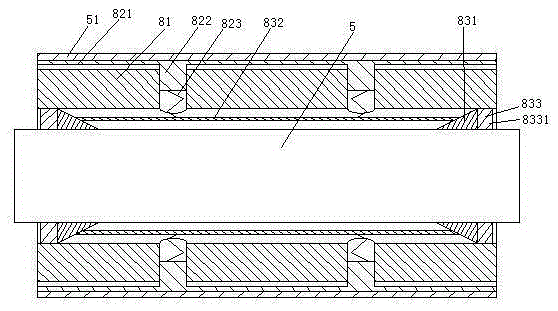

[0024] see figure 2 , between the handle bar 4 and the sleeve 41 is provided with an elastic force adjustment mechanism 8 . The elastic force adjustment mechanism 8 i...

Embodiment 2

[0029] Embodiment two, the difference with embodiment one is:

[0030] see Figure 4 , and also includes a friction wheel 7 and a transmission mechanism 9 . The transmission mechanism 9 includes a first rotating shaft 91, a second rotating shaft 92, a third rotating shaft 93, a first sector gear 94, a second sector gear 95, a third sector gear 96, a fourth sector gear 97, a fifth sector gear 98 and a first sector gear 98. Six sector gear 99. The motor shaft 51 extends in the left-right direction. Both left and right ends of the motor shaft 51 protrude from the motor housing 52 . The grinding head 3 is connected to the left end of the motor shaft 91 . The sixth sector gear 99 is connected to the right end of the motor shaft 51 . The fifth sector gear 98 and the sixth sector gear 99 mesh together. The fifth sector gear 98 is connected to the lower end of the third rotating shaft 93 . The fourth sector gear 97 is connected to the upper end of the third rotating shaft 93 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com