A clarification method for tea soup

A technology for tea soup and tea liquid, applied in the field of tea beverage processing and processing, can solve problems such as being unsuitable for large-scale industrial production, affecting the color and luster quality of tea soup, difficult to control processing conditions, etc., achieving obvious clarification effect, improving overall taste, and good sweetness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

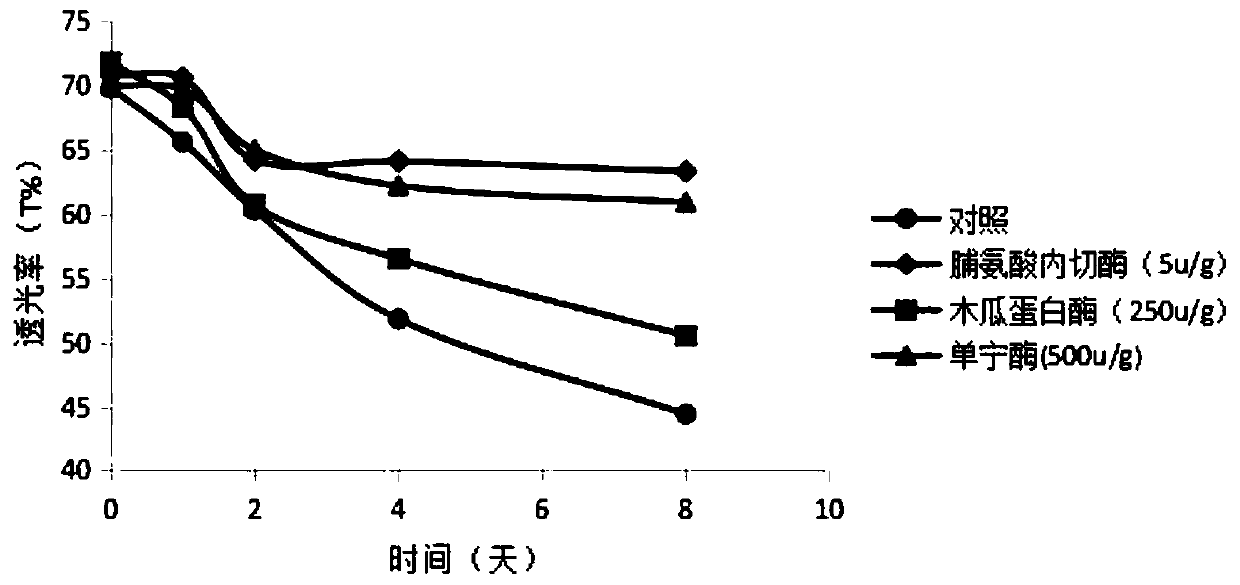

[0027] (1) Tea extraction: use extraction equipment for hot water extraction, put 40g of commercially available Keemun black tea into one part, add 2000g of distilled water, and put the other part into 100g of the same Keemun black tea, add 2000g of distilled water, and extract for 50 minutes. After the extraction, Cool the water at 4-10°C to room temperature, suction filter to obtain clarified tea soup, adjust the concentration of the tea soup to 2% and 5% respectively, pack each into 4 bottles, and put it in a water bath to keep the temperature at 45°C;

[0028] (2) Tea clarification: 50 ppm of proline endonuclease was sequentially added to each portion of clarified tea soup. The enzymatic hydrolysis reaction was 6 hours, and the enzymatic hydrolysis temperature was controlled at 45°C;

[0029] (3) Sterilization: After the enzymatic hydrolysis process, pasteurization was carried out for 30 minutes using 80°C water bath equipment to prepare tea soup, and the light transmittan...

Embodiment 2

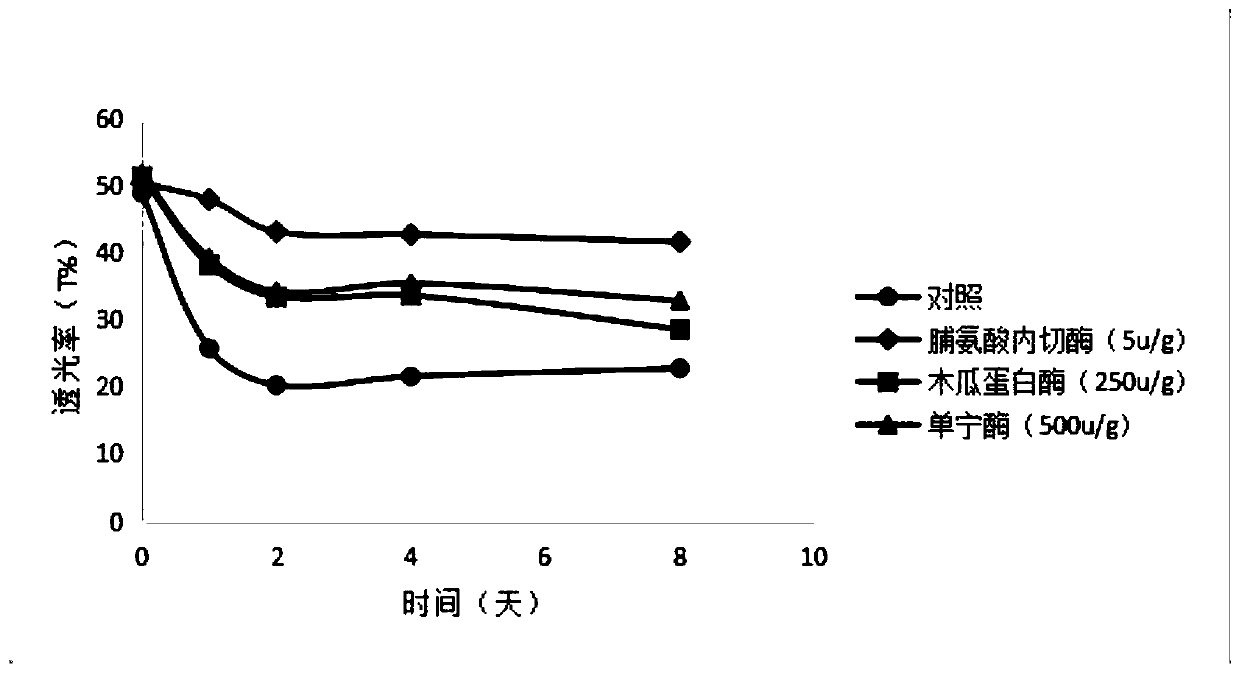

[0031] (1) Tea extraction: use extraction equipment for hot water leaching, put in 40g of tea raw materials, add 2000g of distilled water, and extract for 50min. After the extraction, cool the water at 4-10°C to room temperature, and filter to obtain clarified tea soup. Divide into 6 bottles and put in a water bath to keep the temperature at 45°C;

[0032] (2) Tea clarification: add proline endonuclease in amounts of 12.5ppm, 25ppm, and 50ppm in sequence, enzymolysis for 6 hours, and enzymolysis temperature at 45°C;

[0033] (3) Sterilization: After the enzymatic hydrolysis process, pasteurization was carried out for 30 minutes using 80°C water bath equipment to prepare tea soup, and the light transmittance was measured at a wavelength of 660nm with a spectrophotometer. The experimental data are as follows: image 3 , 4 , 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com