Improved main frame of offshore net cage

A deep-water cage and main frame technology, which is applied in the field of cages in seawater cage aquaculture, can solve the problems of unscientific design of the main frame structure and pipe material of the deep-water cage, damage to the connection between the anchor rope and the main frame of the cage, and I-shaped It can ensure the safety of offshore operations, improve the ability to resist typhoons and prevent risks, and avoid sinking to the seabed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

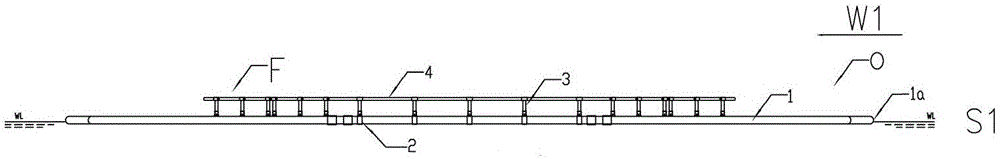

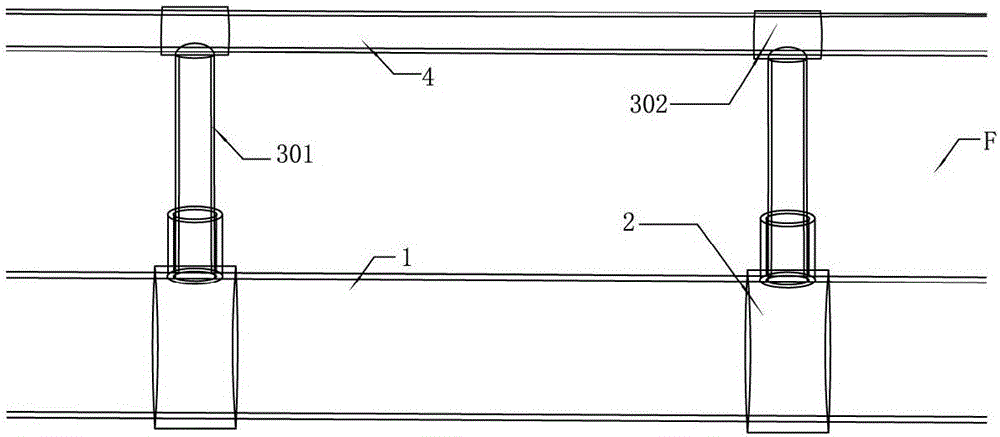

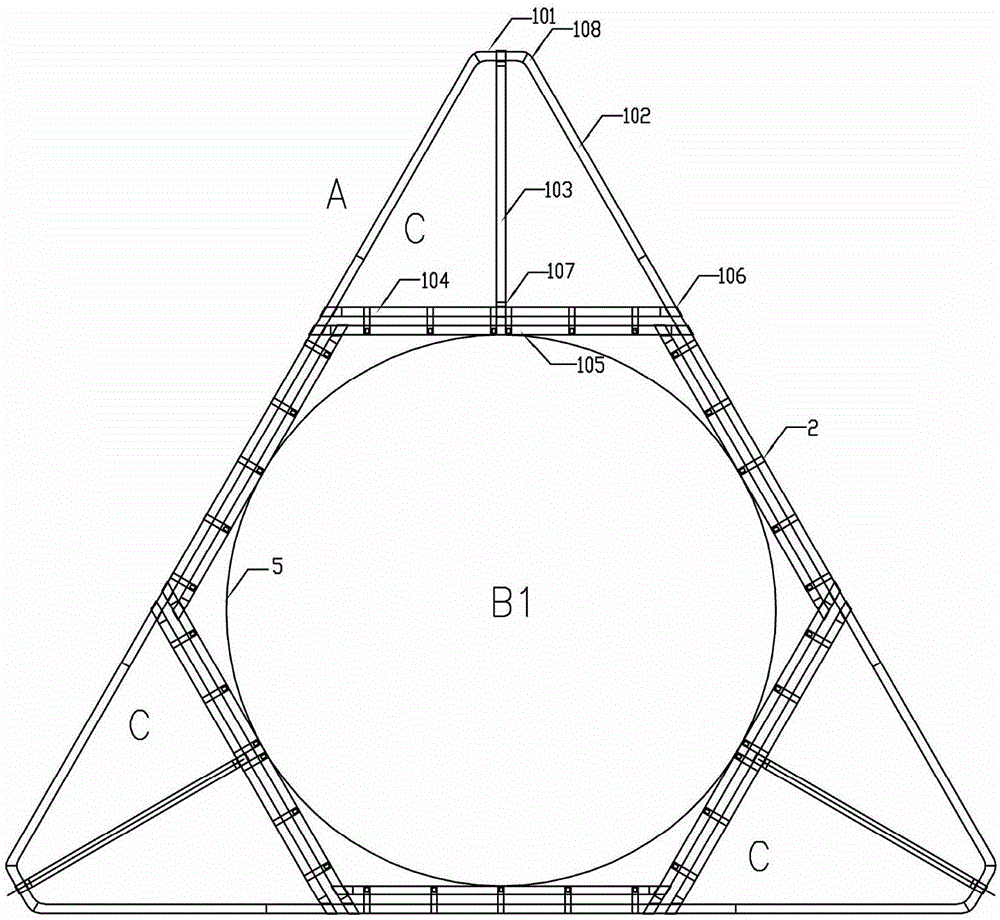

[0065] As shown in Figures 1 to 7, embodiment 1 of the main frame 1 of the improved deep-water net cage of the present invention includes a floating tube in the composition of the main frame, and the floating tube is a hollow elliptical tube with a major axis level, and it is a hollow elliptical tube with a reduction rate of 10. %-20% of round pipes are processed. The reduction rate refers to the percentage of the ratio of the reduction to the diameter of the blank before flattening.

[0066] Specifically: the main frame includes: an equilateral triangular floating tube plane frame and a regular hexagonal central zone floating tube plane frame, three spaced sides of the regular hexagonal central zone floating tube plane frame are parallel to the equilateral triangular floating tube plane frame The midpoints of the three sides and the other three spaced sides are facing the three corners of the equilateral triangle floating tube plane frame and are provided with reinforcing rib...

Embodiment 2

[0104] refer to Figure 8 As shown, the deep-water net cage frame of the second embodiment of the present invention can adopt any one of the pipe construction methods described in the first embodiment. The difference is that the main frame shape is an inner floating pipe connected by an I-shaped frame, and an outer floating pipe. The tube is heat-sealed and welded in an annular shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com