Sapphire crystal ingot profile measuring device

A measurement device, sapphire technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of large and difficult shape measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The objects, features and characteristics of the present invention, as well as the operation method of the relevant elements of the structure and the function and combination of parts will become more apparent when reading the following description and the above claims with reference to the accompanying drawings. It is to be expressly understood that the drawings are for purposes of illustration and description only and are not intended as limitations of the invention.

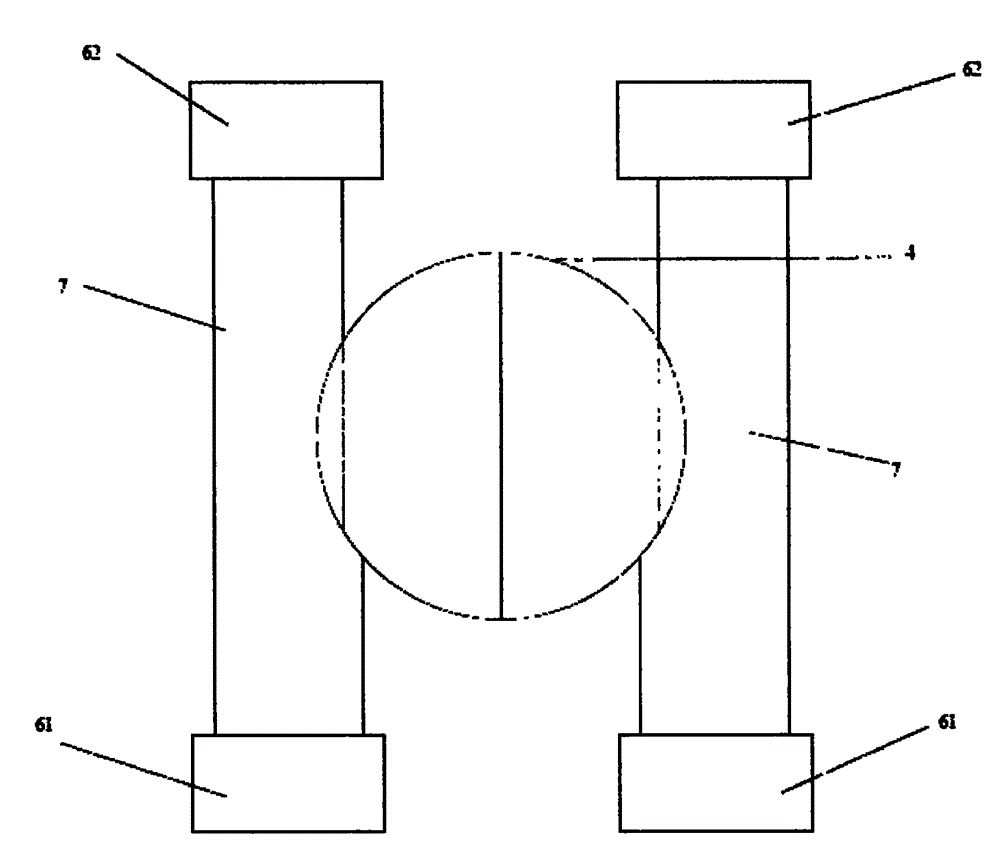

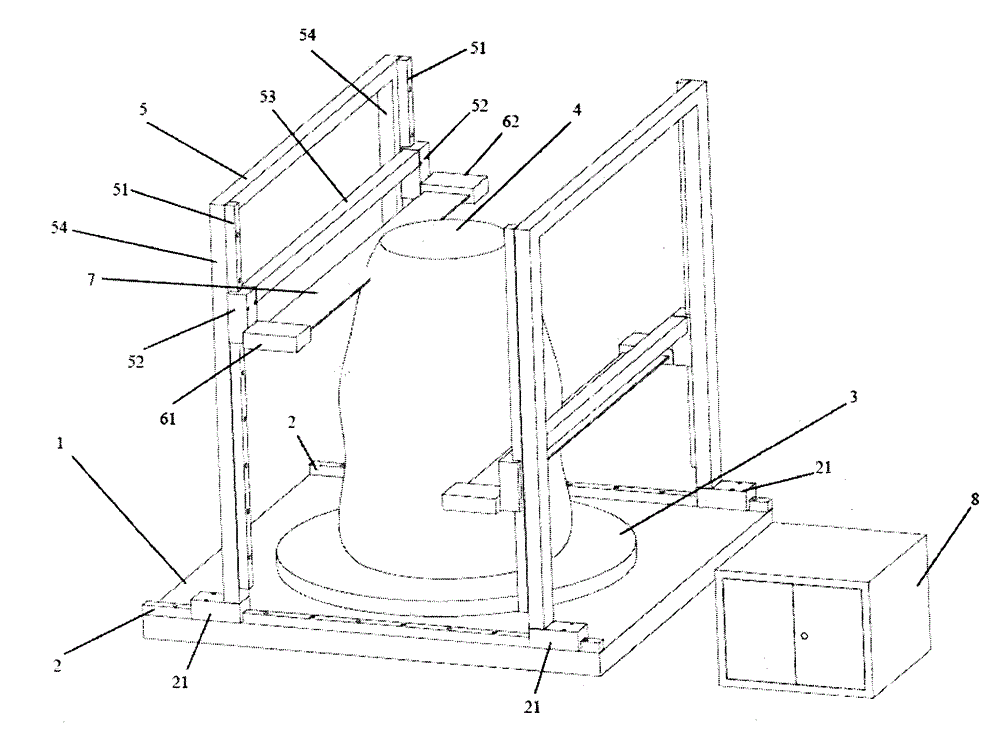

[0015] figure 1 is a schematic diagram of a sapphire crystal ingot shape measuring device according to an embodiment of the present invention. Such as figure 1 As shown, two laterally moving slide rails 2 and a rotating table 3 are fixedly arranged on the base 1 . Wherein, two laterally moving slide rails 2 are arranged on opposite sides of the rotary table 3 , and the sapphire crystal ingot 4 to be measured is fixed on the rotary table 3 . The portal frame is vertically arranged on the base 1, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com