Drying device for chemical raw materials

A technology for drying devices and chemical raw materials, applied in drying, drying machines, heating devices, etc., which can solve the problems of troublesome operation of picking and placing raw materials, complex structure of drying equipment, easy accumulation of particles, etc., to achieve easy operation, reduce Energy waste, not easy to accumulate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

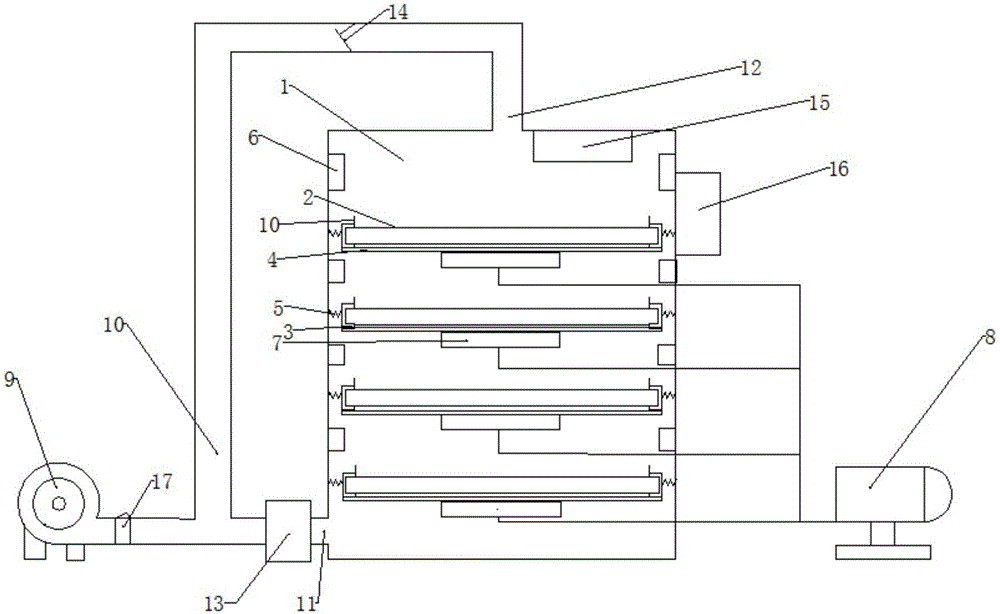

[0020] Such as figure 1 As shown, a chemical raw material drying device includes a drying box 1, a conveying plate 2, a slide rail 3, a supporting plate 4, a spring 5, a heating block 6, a vibration device 7, a motor 8, a blower 9, and an air inlet pipe 11 , an air outlet pipe 12, a heating device 13, a one-way valve 14, a temperature sensor 15, and a controller 16;

[0021] Described drying case 1 is provided with 4 conveying plates 2, and the main body of described drying case 1 is the cuboid shape of vertical placement, and described conveying plate 2 is provided with baffle plate 10 around, and each conveying plate 2 There are slide rails 3 at both ends, one end of the slide rail 3 is connected to the inner wall of the drying box 1 through a spring 5, and the other end of the slide rail 3 is slidingly connected with the transmission plate 2; Supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com