shaft assembly

A technology of shaft assembly and assembly, applied in the direction of bearing elements, shafts, crankshafts, etc., can solve the problems of time-consuming, expensive surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

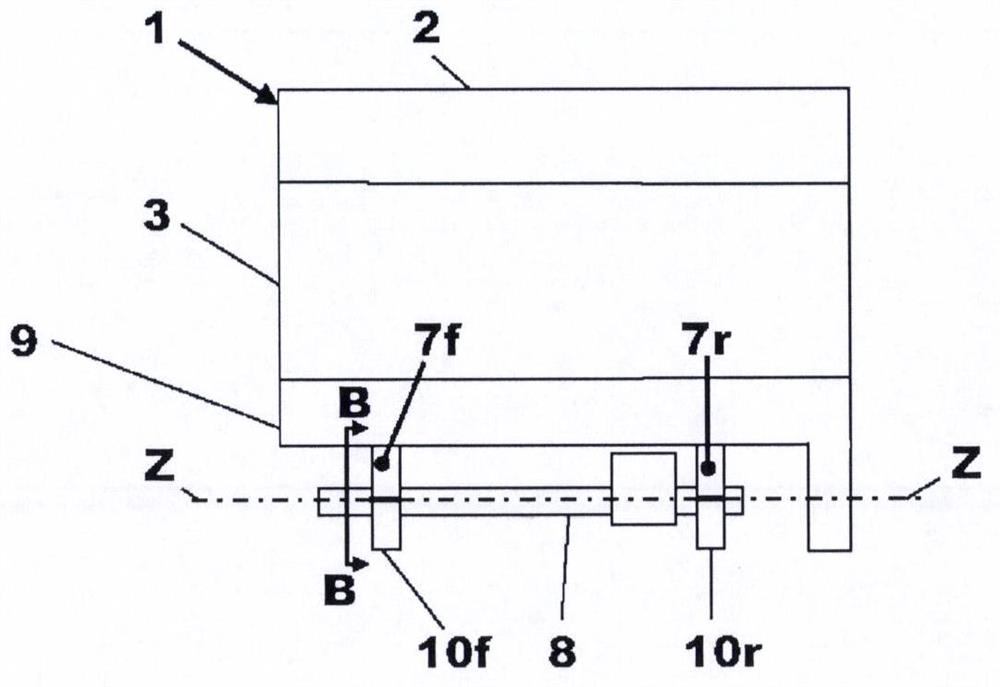

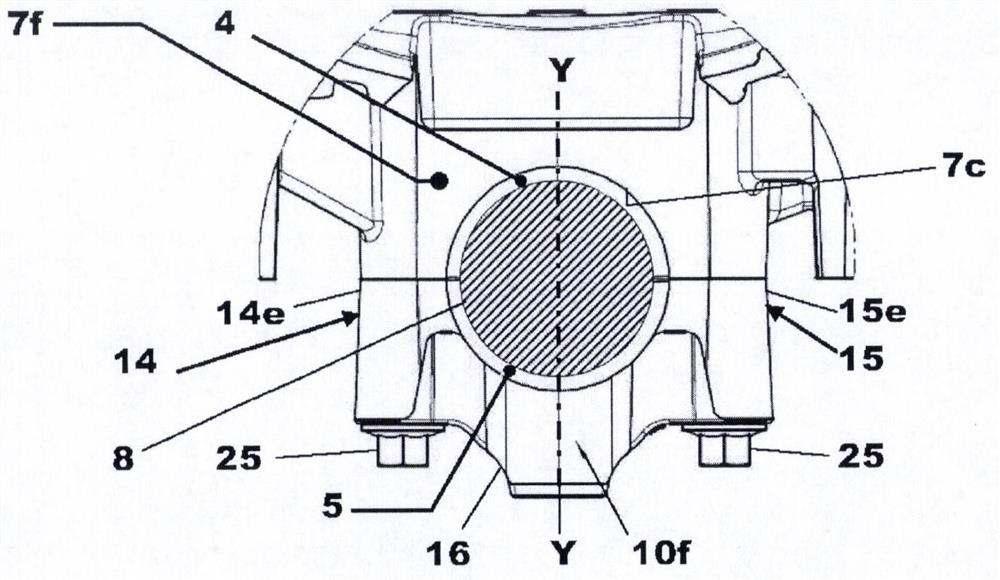

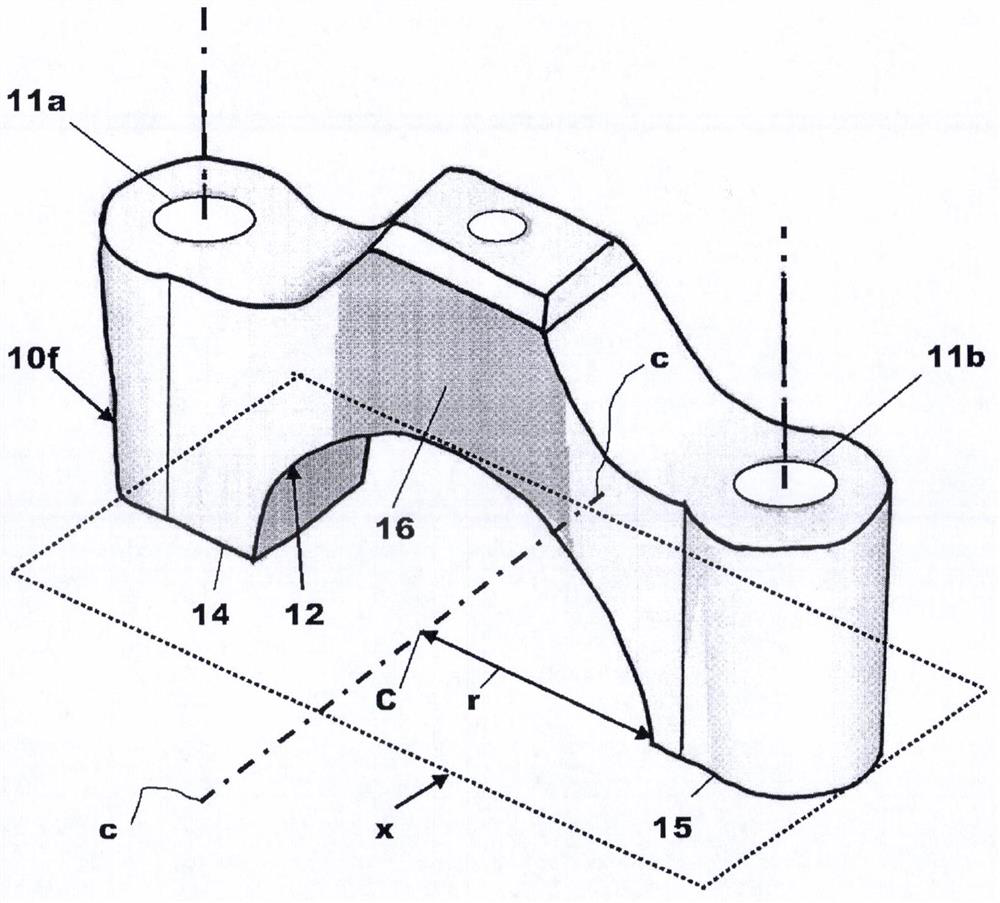

[0046] specific reference Figure 1a , Figure 1b , figure 2 with image 3 , shows an engine 1 having a cylinder head 2 , a cylinder block 3 and a trapezoidal frame 9 bolted to the lower end of the cylinder block 3 . The trapezoidal frame 9 defines at the lower end a front bearing support structure 7f and a rear bearing support structure 7r, to each of which a respective error proof bearing cap 10f, 10r is bolted by a pair of bolts 25 . The front bearing cap 10f is bolted to the front bearing support structure 7f and the rear bearing cap 10r is bolted to the rear bearing support structure 7r.

[0047] In the exemplary case where the shaft 8 is an engine balancer shaft, the shaft 8 is rotatably supported by the front bearing cap 10f and the rear bearing cap 10r and the front bearing support structure 7f and the rear bearing support structure 7r to form a shaft and bearing assembly. In the example case, the shaft 8 is rotatably supported by two bearing support assemblies 7f,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com