Crude oil single well metering and measuring system

A measurement system and flow measurement technology, applied in measurement, wellbore/well components, construction, etc., can solve problems such as inability to meet measurement requirements, low automation processing capacity, and large equipment on-site maintenance, to improve oil well measurement efficiency, The effect of improving oil well measurement accuracy and reducing on-site labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

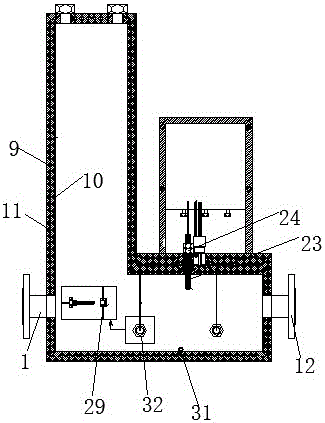

[0032] A crude oil single well metering and measuring system, comprising a casing, a main controller, a receiving terminal, a flow measurement assembly, a density measurement assembly, and a temperature measurement assembly, the casing includes an inner casing and an outer casing, the inner casing Insulation cotton is arranged between the layer shell and the outer shell, a heat transfer oil storage room is arranged in the inner shell, an explosion-proof box bracket is set on the outer shell, and an explosion-proof box bracket is connected to the explosion-proof box bracket. The explosion-proof box is equipped with a converter, an air switch and a heating cable inside the converter. The heating cable is located inside the converter. The air switch controls the opening and closing of the heating cable. heat preservation system, the flow measurement component is arranged in the inner shell, the density measurement component and the temperature measurement component are all set on ...

Embodiment 2

[0035]In another specific embodiment of the present invention, the difference from Example 1 is that the flow measurement assembly includes a flow meter pipe, a flow meter pressure-taking short pipe, a wedge-shaped throttling piece, a pipe connecting flange, and a flow pressure-taking connecting pipe , flow pressure-taking connection flange, flow transmitter pressure-taking flange and flow transmitter, the pipeline connection flange is welded on both ends of the flowmeter pipeline, and the wedge-shaped throttling piece is welded on the flowmeter On the side, the short pressure-taking tube of the flowmeter is welded on both sides of the wedge-shaped throttling piece, the short pressure-taking tube of the flowmeter is welded with the flow pressure-taking connection pipe, and the flow-pressure-taking connection pipe is welded on the flow pressure-taking connection pipe Lan, the pressure-taking flange of the flow transmitter is connected with the pressure-taking connecting flange o...

Embodiment 3

[0037] Such as figure 1 , figure 2 , image 3 and Figure 4 A crude oil single well metering and measuring system shown includes:

[0038] The shell, which includes an inner shell 10 and an outer shell 9, insulation cotton 11 is arranged between the inner shell and the outer shell, a heat transfer oil storage room is arranged in the inner shell, and a heat transfer oil storage chamber is arranged on the outer shell An explosion-proof box bracket 14 is provided, an explosion-proof box 15 is connected to the explosion-proof box bracket, and a converter 16, an air switch and a heating cable are arranged inside the explosion-proof box;

[0039] The flow measurement assembly is set in the housing. The flow measurement assembly includes a flow measurement assembly including a flowmeter pipe 1, a flowmeter pressure-taking short pipe 2, a wedge-shaped throttling piece 3, a pipe connecting flange 12, a flow pressure-taking connecting pipe, Flow pressure-taking connecting flange 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com