Heat insulation roof exhaust pipeline system and construction method

An exhaust duct and construction method technology, applied in the direction of roof, ventilation system, roof covering layer, etc., can solve the problems of construction quality of thermal insulation layer roof exhaust duct, achieve good air diffusion, solve leakage problems, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

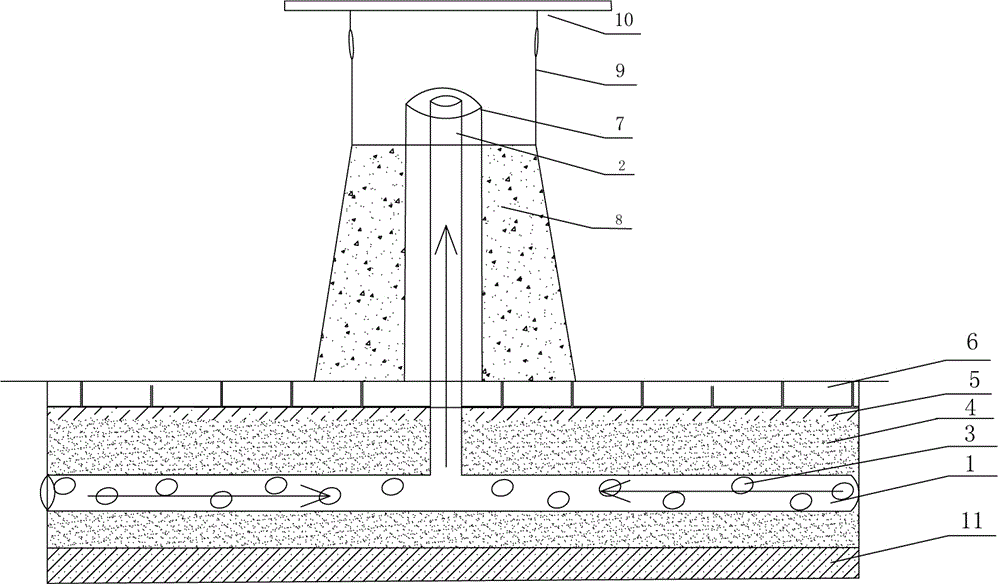

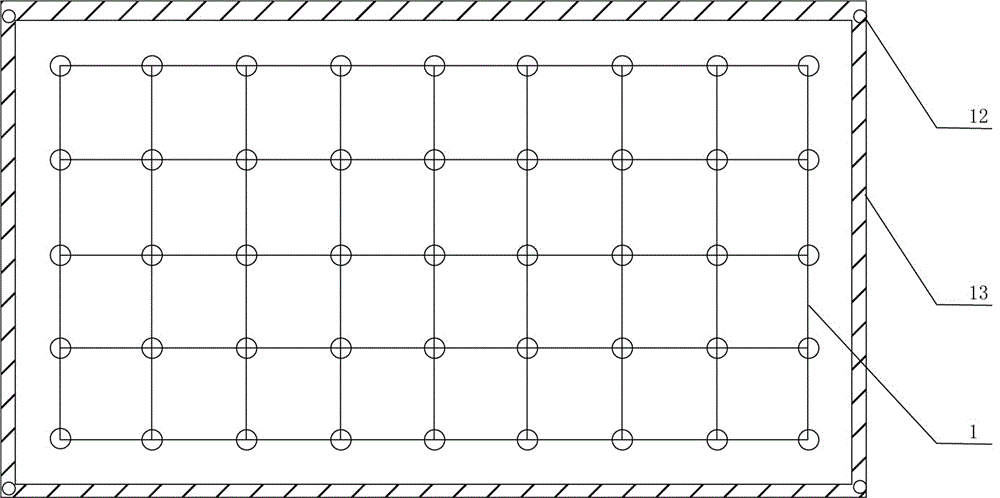

[0030] Such as Figure 1-2 As shown, a thermal insulation roof exhaust duct system includes the first exhaust duct 1 arranged horizontally and vertically, the distance between the branch pipes in the first exhaust duct 1 arranged side by side is 5.5m, and the parallel longitudinal The distance between each branch pipe in the first exhaust pipe 1 is 5.3m, and the distance between the outermost exhaust pipe in the first exhaust pipe 1 and the gutter around the roof is 2.5m. A plurality of quincunx-shaped exhaust holes 3 are evenly distributed along the length direction of the first exhaust pipe 1 . The plum blossom shape of the exhaust hole can ensure that the wall of the exhaust pipe will not be damaged during the drilling process, but the number of apertures is sufficient within the limited exhaust range. The pore diameter is required to be no larger than the particle size of light ceramsite to prevent ceramsite from entering the pipe. The spacing between each exhaust hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com