Overall post-pouring type industrial building system and construction method thereof

An integral and architectural technology, applied in the direction of architecture, building components, building structures, etc., can solve the problems of complex pouring process, poor physical and mechanical properties of buildings, and production, processing and transportation without considering the overall structure of buildings. Achieve batch processing and installation, reduce transportation volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

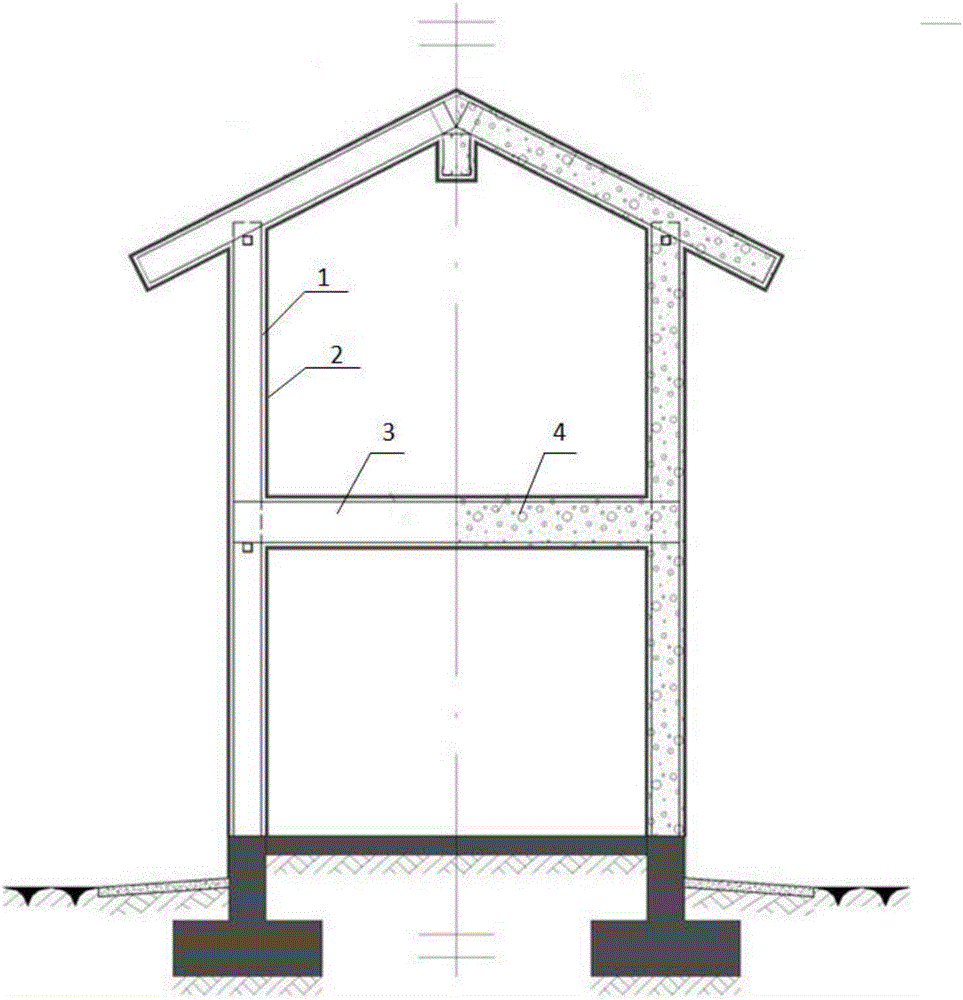

[0060] refer to figure 1 , an integral post-cast industrialized building system, including:

[0061] Structural skeleton 1, which adopts a modular assembly method;

[0062] The plate system 2, which wraps the inner and outer sides of the structural skeleton 1 to form a wall, floor, and roof structure;

[0063] The cavity 3 is formed by the mutual sealing of the plate system 2, and penetrates through the wall, floor and roof structure;

[0064] Filling material 4, which is evenly poured in the cavity 3;

[0065] After the filling material 4 is poured into the cavity 3 and solidified, the wall, floor, and roof structures form an integrated shell structure.

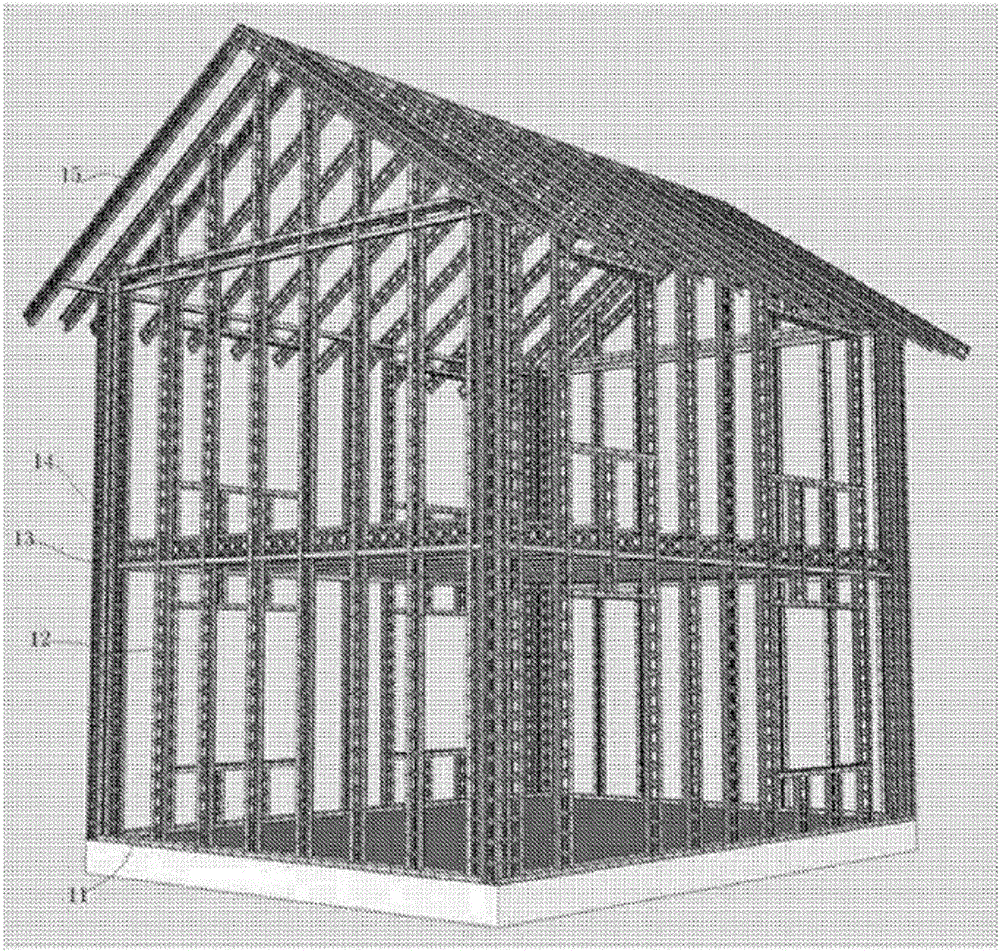

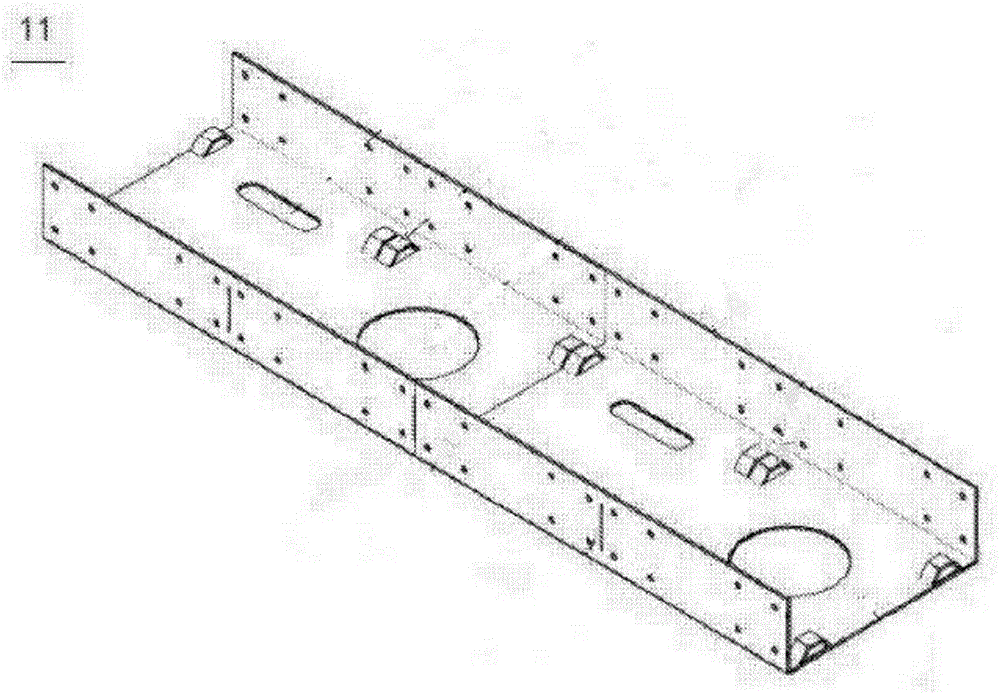

[0066] refer to figure 2 , as a preferred solution, the structural skeleton 1 is a steel structural skeleton, and the structural skeleton 1 includes a steel ground beam 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com