Construction method of high vertical straw sand barrier suitable for strong wind area

A construction method and high-vertical technology, applied in construction, soil protection, infrastructure engineering, etc., can solve problems such as grid holes, unsuitable for strong wind areas, grid and column suspension, etc., to enhance the ability to resist strong winds ability, increase the horizontal tensile strength, and improve the effect of surface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

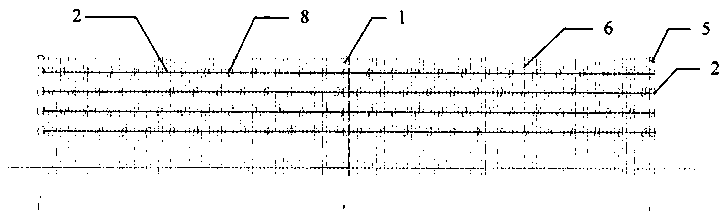

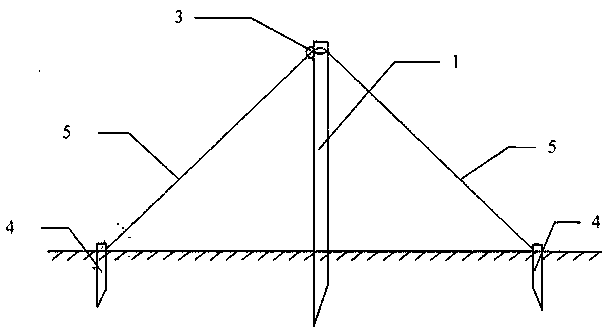

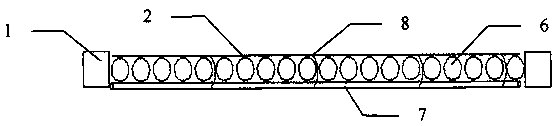

[0020] A method for constructing a high vertical straw sand barrier suitable for strong wind areas according to the present invention, the sand barrier involved in the method is composed of fixed piles, anchor piles, anchor cables, straw, reinforcing ribs, cross bars and fixed wires. Composition, longitudinally equidistant or unequal-distance fixed reinforcing ribs 2 on the fixed pile 1, the distance between the fixed piles 1 is 2-4m; at the intersection of the reinforced ribs 2 on the side of the fixed pile 1, fix the reinforced ribs 2 with U-shaped nails 3; On the windward side of the rib 2, the cut straw 6 is leaned against the reinforcing rib 2, the straw 6 is clamped along the reinforcing rib 2 with the cross bar 7, and the reinforcing rib 2, the straw 6 and the cross bar 7 are bound and fixed with the fixing wire 8, The distance between the fixed wire 8 nodes is 10-30cm; the anchor pile 4 is fixed on the ground at 1.5m on the windward side and the leeward side of the fixe...

Embodiment 2

[0026] A kind of construction method of the high vertical straw sand barrier suitable for strong wind area according to the present invention, the sand barrier involved in this method is according to embodiment 1, concrete operation is carried out according to the following steps:

[0027] a. Measure and set out according to the design, draw the position line of the sand barrier on the ground, nail the fixed pile 1 into the soil with a hammer, keep the distance between the fixed piles 1 at 3m; wind the reinforcing rib 2 at the longitudinal unequal distance on the fixed pile Tighten and tighten in one circle, and fix the reinforcement rib 2 at the intersection of the reinforcement rib 2 on the side of the fixed pile 1; the U-shaped nail 3 is a U-shaped iron nail with a diameter of 3mm and a length of 30mm; use the same method, sequentially Connect and fix with other fixed piles 1;

[0028] b. Vertical to the laying direction of the sand barrier, use a hammer to vertically drive...

Embodiment 3

[0032] A kind of construction method of the high vertical straw sand barrier suitable for strong wind area according to the present invention, the sand barrier involved in this method is according to embodiment 1, concrete operation is carried out according to the following steps:

[0033] a. Measure and set out according to the design, draw the position line of the sand barrier on the ground, nail the fixed pile 1 into the soil with a hammer, keep the distance between the fixed piles 1 at 4m; wind the reinforcing rib 2 at the longitudinal equidistant position on the fixed pile Tighten the circle, tighten it, fix it with U-shaped nail 3 at the intersection of reinforcement rib 2 on the side of fixed pile 1, and use the same method to connect and fix it with other fixed piles 1 in sequence;

[0034] b. Vertical to the laying direction of the sand barrier, use a hammer to vertically drive the anchor pile 4 into the ground at 3m from the windward side and the leeward side of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com