A kind of hand-painted water-based matt oil canvas and preparation method thereof

A kind of oil canvas, water-based technology, applied in the direction of coating, textiles, papermaking, starch coating, etc., can solve the problems that the texture of the base fabric cannot be reflected, the expression effect is reduced, etc., and it is not easy to yellow and wrinkle, easy to mount, and stable in color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

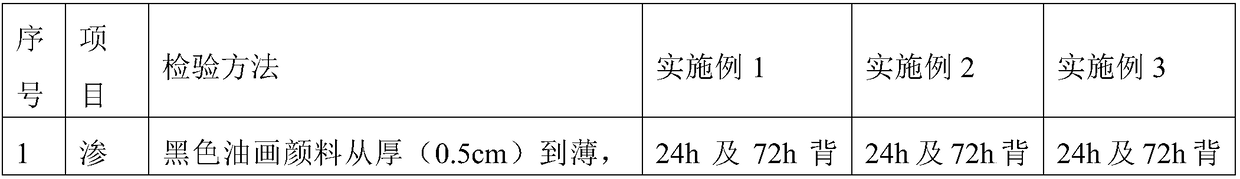

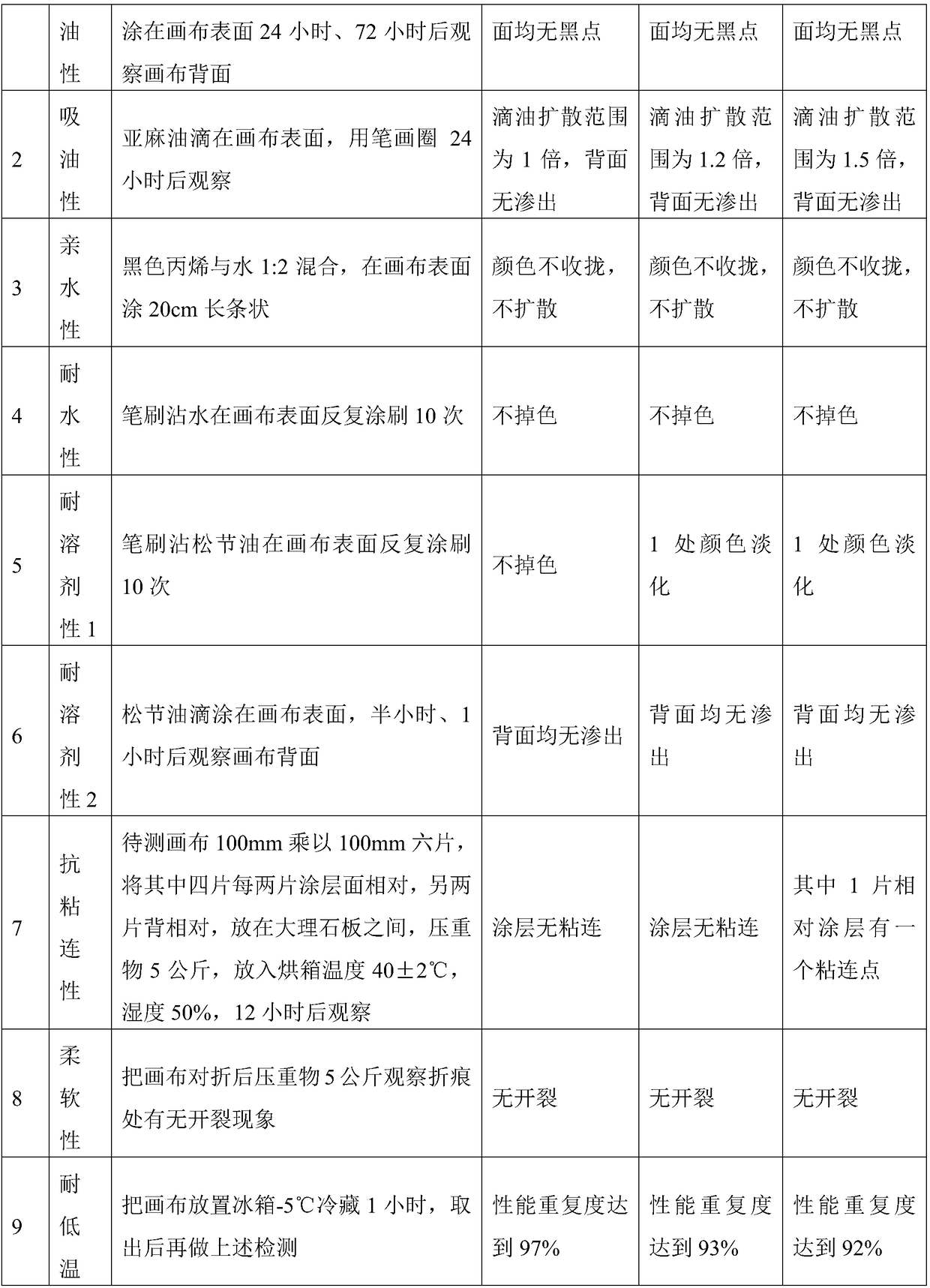

Embodiment 1

[0019] A kind of hand-painted water-based matte oil canvas, its preparation method comprises the steps:

[0020] (1) Clear glue layer material: Mix 2 parts of trimethylolpropane triacrylate, 1.5 parts of epoxy acrylate, and 2.5 parts of absolute ethanol, and then mix them with 22 parts of acrylate adhesive, 21 parts of starch, Mix 6 parts of alum and 12 parts of deionized water and stir evenly;

[0021] (2) Undercoat material: mix 6 parts of silicon dioxide, 31 parts of calcium carbonate, 12 parts of titanium dioxide, 21 parts of acrylate adhesive, 2.5 parts of brightener, and 22 parts of deionized water and stir evenly;

[0022] (3) Surface coating material: mix 11 parts of calcium carbonate, 22 parts of silicon dioxide, 17 parts of deionized water, 12 parts of acrylate adhesive, and 4.5 parts of surfactant and stir evenly;

[0023] (4) Carry out calendering treatment to the cotton gray cloth first, then spray the glue-clearing layer, and then dry it in an oven. 5.5m / min; ...

Embodiment 2

[0028] A kind of hand-painted water-based matte oil canvas, its preparation method comprises the steps:

[0029] (1) Clear glue layer material: mix 1-3 parts of trimethylolpropane triacrylate, 1 part of epoxy acrylate, and 2 parts of absolute ethanol, and then mix them with 20 parts of acrylate adhesive and 20 parts of starch part, 5 parts of alum, and 10 parts of deionized water are mixed and stirred evenly;

[0030] (2) Primer coating material: mix 5 parts of silicon dioxide, 30 parts of calcium carbonate, 10 parts of titanium dioxide, 20 parts of acrylate adhesive, 2 parts of brightener and 20 parts of deionized water and stir evenly;

[0031] (3) Surface coating material: mix 10 parts of calcium carbonate, 20 parts of silicon dioxide, 15 parts of deionized water, 10 parts of acrylate adhesive, and 4 parts of surfactant and stir evenly;

[0032] (4) Carry out calendering treatment to the polyester-cotton gray cloth first, then spray the glue-clearing layer, and then dry it...

Embodiment 3

[0037] A kind of hand-painted water-based matte oil canvas, its preparation method comprises the steps:

[0038] (1) Clear glue layer material: mix 3 parts of trimethylolpropane triacrylate, 2 parts of epoxy acrylate, and 3 parts of absolute ethanol, and then mix them with 24 parts of acrylate adhesive, 22 parts of starch, Mix 8 parts of alum and 14 parts of deionized water and stir evenly;

[0039] (2) Undercoat material: mix 7 parts of silicon dioxide, 32 parts of calcium carbonate, 15 parts of titanium dioxide, 23 parts of acrylate adhesive, 3 parts of brightener, and 25 parts of deionized water and stir evenly;

[0040] (3) Surface coating material: mix 12 parts of calcium carbonate, 23 parts of silicon dioxide, 18 parts of deionized water, 13 parts of acrylate adhesive, and 5 parts of surfactant and stir evenly;

[0041] (4) Carry out calendering treatment to the cotton gray cloth first, then spray the glue-clearing layer, and then dry it in an oven. 5 m / min;

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com