Filtering device of flocculation washing machine and flocculation washing machine

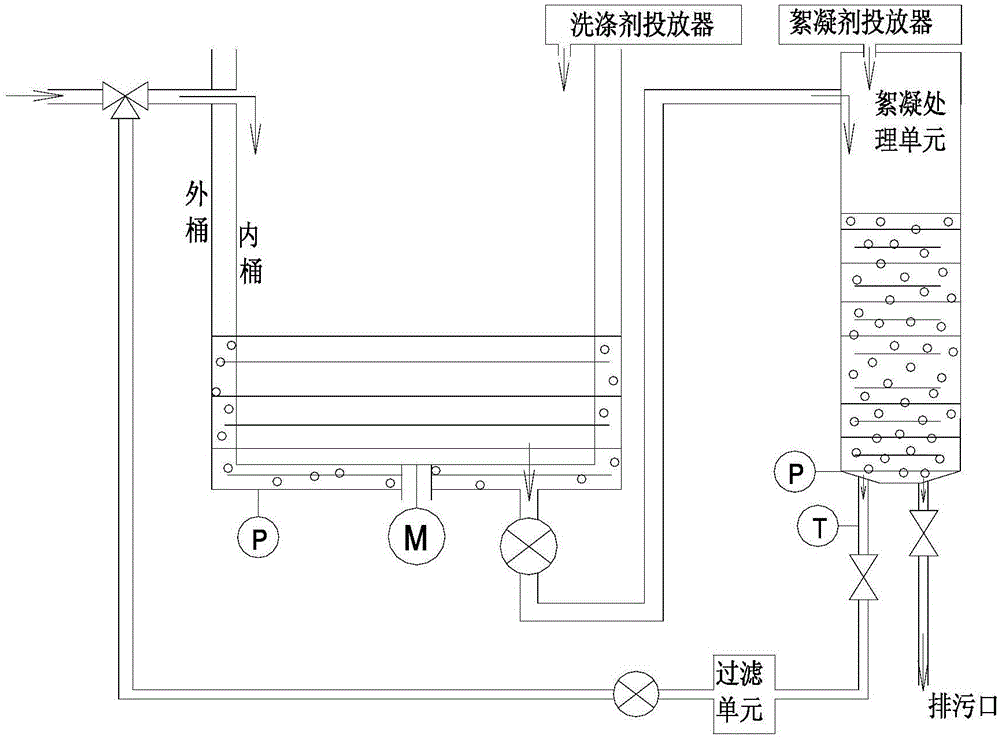

A technology of flocculation washing machine and filter device, which is applied in the field of washing machines, can solve the problems of reduced filtration efficiency, blockage of filter elements, and large amount of flocs remaining, and achieves remarkable effects, simple structure, and suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

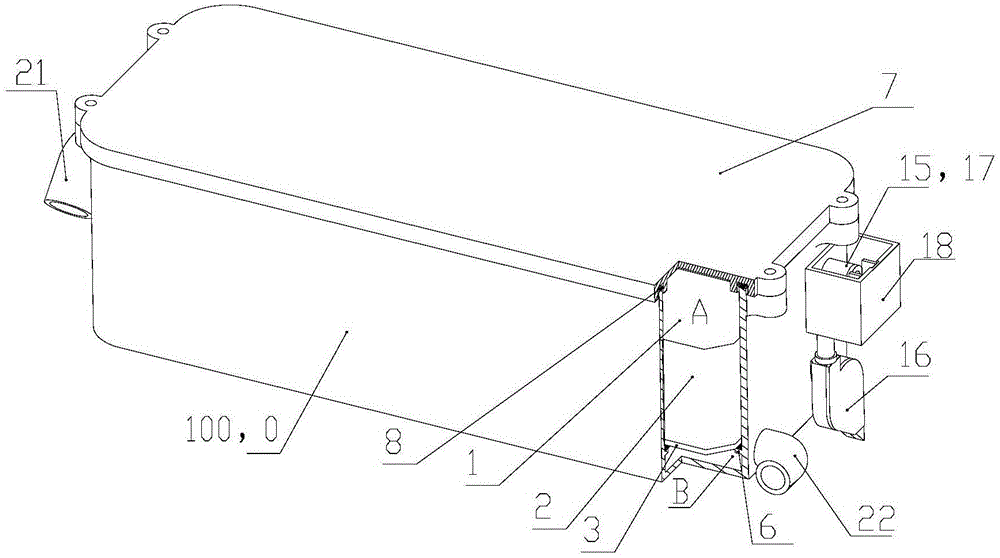

[0046] Such as figure 2 with image 3 As shown, in this embodiment, the first port 21 set in the upper filter chamber A of the filter device 100 is the water inlet, the second port 22 set in the lower filter chamber B is the water outlet, and the first port 21 communicates with the flocculation bucket 20 , the second port 22 communicates with the outer barrel. The flocculation water in the flocculation barrel 200 flows into the upper filter cavity A from the first port 21, and then is filtered through the filter element 2, and then the filtered clean water flows into the lower filter cavity B and flows back into the outer barrel through the second port 22, while The flocs remain in the upper filter chamber A of the filter chamber 11 to achieve the purpose of filtering the flocculated water and returning clean water for subsequent rinsing.

[0047] Such as figure 2 with Figure 4 As shown, in this embodiment, the filter element 2 is placed on the support frame 3 , and the...

Embodiment 2

[0052] Such as Figure 5 As shown, in the present embodiment, the first port 21 set in the upper filter chamber A of the filter device 100 is a water outlet, the second port 22 set in the lower filter chamber B is a water inlet, and the second port 22 is connected to the flocculation bucket 20 are connected, and the first port 21 is connected with the outer barrel. After the flocculation water in the flocculation bucket 200 flows in from the second port 22 and fills the lower part B of the filter chamber, as the water level rises, the incoming water is filtered by the filter element 2, and the filtered clean water flows into the upper filter chamber A and passes through the second filter chamber. A port 21 flows back into the outer barrel, while the flocs are retained in the lower filter cavity B, which can also achieve the purpose of filtering the flocculation water and returning clean water for subsequent rinsing.

[0053] In this embodiment, the filter cavity 1 formed by t...

Embodiment 3

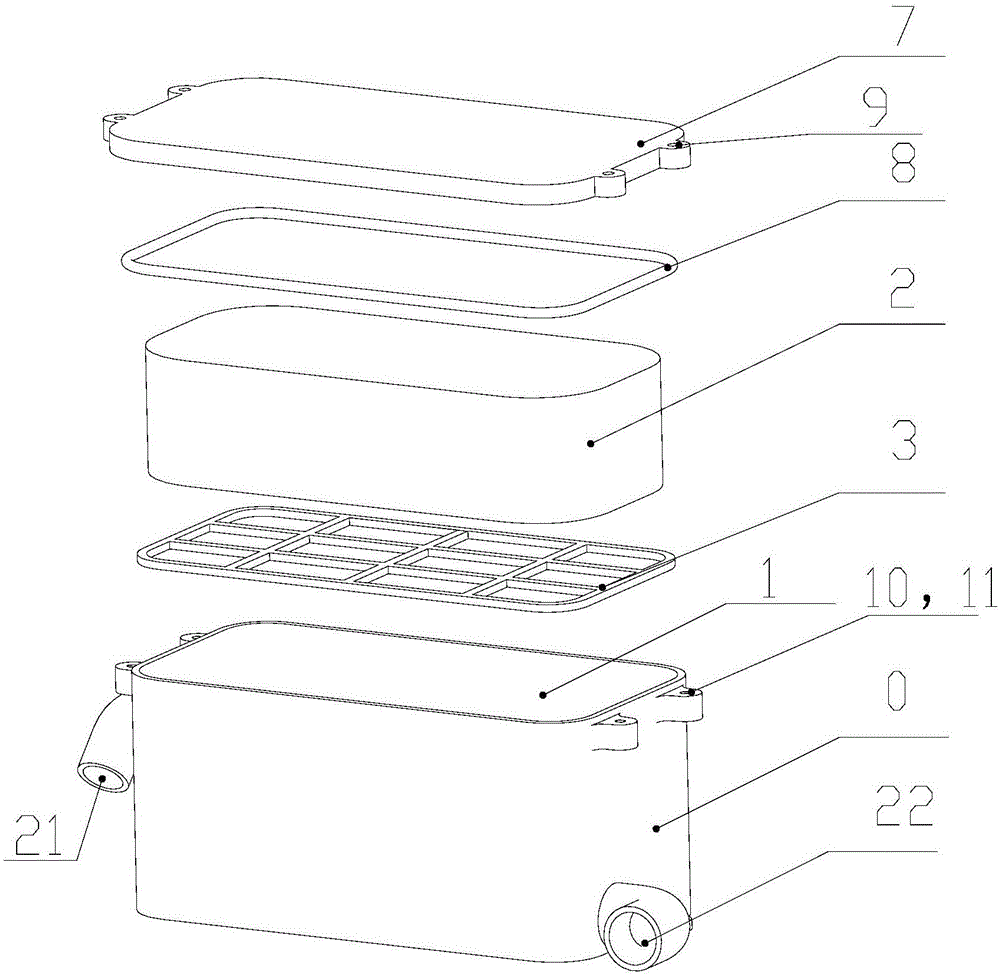

[0056] Such as Image 6 As shown, in this embodiment, the housing 0 of the filter device 100 includes a detachable upper cover 7, the upper cover 7 is fastened and installed on the top of the housing 0, and the upper cover 7 is connected to the side of the housing 0 A sealing ring 8 is provided at the contact position of the top of the wall. Thus, the upper cover 7 is detachably fastened with the housing 0 , and the contact gap of the upper cover 7 is sealed through the sealing ring 8 .

[0057] In this embodiment, at least one pair of buckle strips 12 protruding from the outer periphery of the upper cover 7 is provided. It can be in a horizontal or vertical state under the action of external force. A protruding buckle 14 is provided on the lower side of the buckle bar 12 , and a buckle 13 protruding outward horizontally is provided on the corresponding side wall of the housing 0 to cooperate with the buckle 14 .

[0058] Preferably, the upper cover 7 is made of a square pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com