Ganoderma lucidum spores oil

A technology of Ganoderma lucidum spore oil and Ganoderma lucidum spore powder, which is applied in the direction of fat oil/fat production, fat oil/fat refining, plant raw materials, etc. It can solve the problems that cannot be completely preserved, the quality of raw materials is average, and the effective ingredients cannot be retained, so as to achieve clear oil products Clear, low residual extraction solvent, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of broken ganoderma lucidum spore powder:

[0026] (1) Raw material preparation: take the ganoderma lucidum spore powder raw material, wash with water, and remove impurities;

[0027] (2) Vacuum drying: set the vacuum degree and vacuum drying time, the vacuum degree is 0.9MPa, the vacuum drying time is 6h, so that the moisture after vacuum drying is ≤6%;

[0028] (3) Freeze embrittlement and wall breaking: place the vacuum-dried raw materials at -18°C for embrittlement for 4 hours; then at 55°C, carry out ultrasonic mixing to break the wall. The time is 8 minutes, the mixing speed is 35 rpm, and the broken ganoderma spore powder is obtained.

[0029] Preparation of ganoderma lucidum spore oil:

[0030] (1) Raw material granulation: take the above-mentioned broken ganoderma lucidum spore powder, add purified water to mix and granulate, the mass ratio of the broken ganoderma lucidum spore powder:purified water is=1:0.3; the granulation adopts a rotary granul...

Embodiment 2

[0036] Preparation of broken ganoderma lucidum spore powder:

[0037] (1) Raw material preparation: take the ganoderma lucidum spore powder raw material, wash with water, and remove impurities;

[0038] (2) Vacuum drying: set the vacuum degree and vacuum drying time, the vacuum degree is 0.9MPa, the vacuum drying time is 6h, so that the moisture after vacuum drying is ≤6%;

[0039] (3) Freeze embrittlement and wall breaking: place the vacuum-dried raw materials at -18°C for embrittlement for 4 hours; then at 55°C, carry out ultrasonic mixing to break the wall. The time is 8 minutes, the mixing speed is 35 rpm, and the broken ganoderma spore powder is obtained.

[0040] Preparation of ganoderma lucidum spore oil:

[0041] (1) Raw material granulation: take the above-mentioned broken ganoderma lucidum spore powder, add purified water to mix and granulate, the mass ratio of the broken ganoderma lucidum spore powder:purified water is=1:0.4; the granulation adopts a rotary granul...

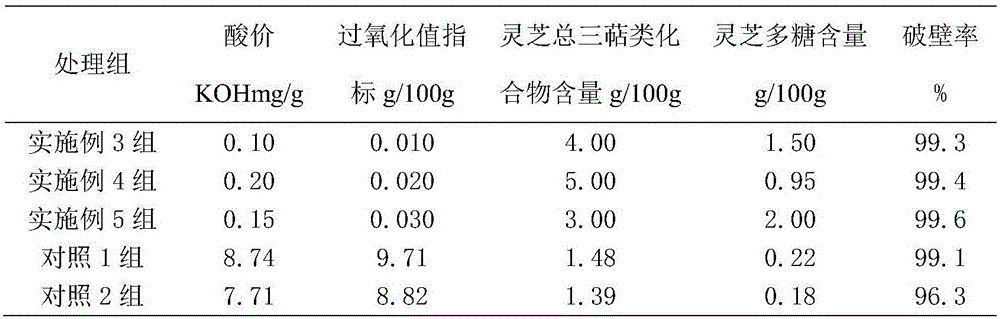

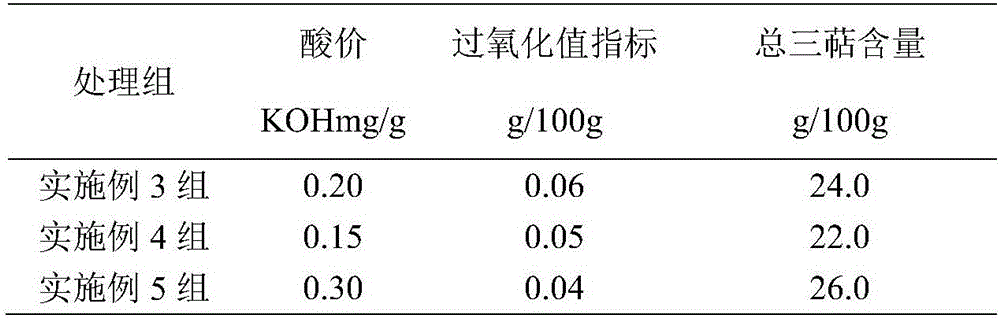

Embodiment 3

[0047] Preparation of broken ganoderma lucidum spore powder:

[0048] (1) Raw material preparation: take the ganoderma lucidum spore powder raw material, wash with water, and remove impurities;

[0049] (2) Vacuum drying: set the vacuum degree and vacuum drying time, the vacuum degree is 0.9MPa, the vacuum drying time is 6h, so that the moisture after vacuum drying is ≤6%;

[0050] (3) Freeze embrittlement and wall breaking: place the vacuum-dried raw materials at -18°C for embrittlement for 4 hours; then at 55°C, carry out ultrasonic mixing to break the wall. The time is 8 minutes, the mixing speed is 35 rpm, and the broken ganoderma spore powder is obtained.

[0051] Preparation of ganoderma lucidum spore oil:

[0052] (1) Raw material granulation: take the above-mentioned broken ganoderma lucidum spore powder, add purified water to mix and granulate, the mass ratio of the broken ganoderma lucidum spore powder:purified water is =1:0.35; the granulation adopts a rotary granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com