Optimized utilization method for light naphtha

A technology of light naphtha and light removal tower, applied in chemical instruments and methods, organic chemistry, hydrocarbons and other directions, to achieve the effect of improving utilization rate, low energy consumption, high product purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

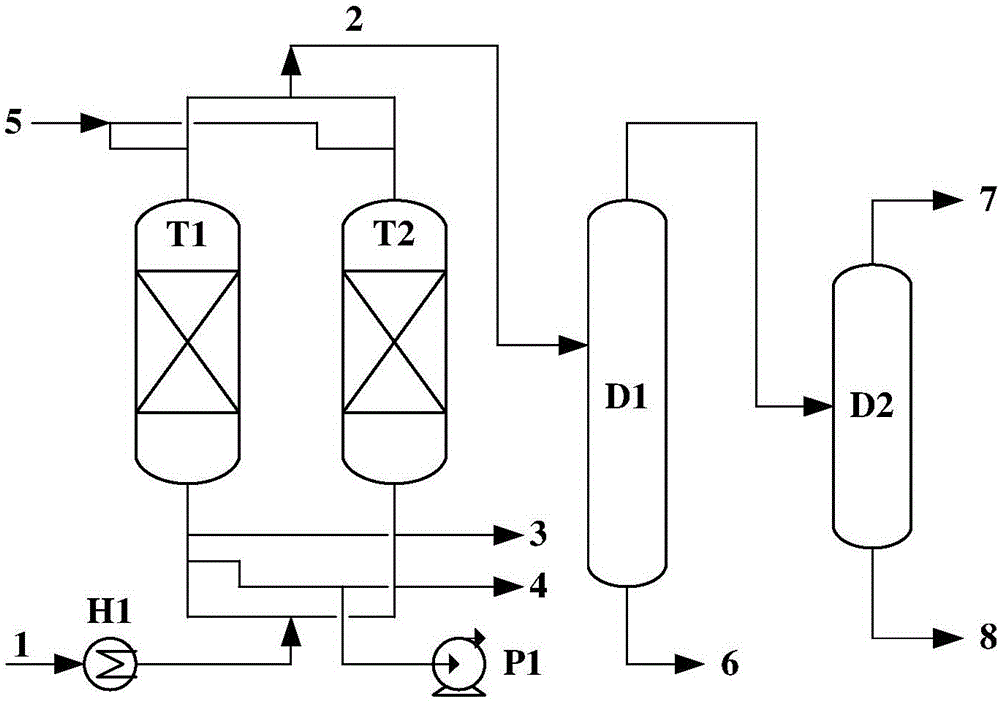

Image

Examples

Embodiment 1

[0029] Light naphtha with a normal paraffin content of 25% enters the vaporizer H1 and is vaporized at 150°C and 0.7MPa. The n-alkanes in the naphtha are adsorbed by mordenite, and the residual oil flows out from the outlet of the adsorption tower, wherein the n-alkanes content is 0.3%;

[0030] After the adsorption process is over, use nitrogen for intermediate replacement under the conditions of 150°C and 0.2MPa to purge out the materials in the dead space of the bed for 5 minutes;

[0031] After the intermediate replacement process is completed, desorption is carried out by combining vacuum pumping and nitrogen purging. Under the conditions of 150°C and 0.05MPa, the normal alkanes adsorbed in the mordenite are desorbed for 25 minutes, and the normal alkanes in the desorbed oil The alkane content is 99.5%, and the ethylene yield is 41.8% when used as ethylene cracking material.

[0032] The suction residue oil of above-mentioned adsorption separation unit enters deweighting...

Embodiment 2

[0034] Light naphtha with a normal paraffin content of 25% enters the vaporizer H1 and is vaporized at 80°C and 0.15MPa. The n-alkanes in the naphtha are adsorbed by mordenite, and the residual oil flows out from the outlet of the adsorption tower, wherein the n-alkanes content is 0.25%;

[0035] After the adsorption process, at 80°C, reduce the pressure in the bed to 0.1MPa, and discharge the material in the dead space by reducing the bed pressure for 5 minutes;

[0036] After the intermediate replacement process, the bed is evacuated to 0.1×10 -3 MPa, at 80°C, 0.1×10 -3 Carry out vacuum desorption under the condition of MPa, desorb the n-alkanes adsorbed in the mordenite for 25 minutes, the content of n-alkanes in the desorbed oil is 99.3%, and the yield of ethylene when used as ethylene cracking material is 41.7%.

[0037] The suction residue oil of above-mentioned adsorption separation unit enters deweighting D1, and plate number is 40, and feed plate is the 40th, and re...

Embodiment 3

[0039] The light naphtha with a n-paraffin content of 35% enters the vaporizer H1 and is vaporized at 350°C and 9.5MPa. After 10 minutes of adsorption, the n-alkanes in the light naphtha were adsorbed by the SAPO-17 aluminum phosphate molecular sieve, and the residual oil flowed out from the outlet of the adsorption tower, wherein the n-alkanes content was 0.15%;

[0040] After the adsorption process is over, nitrogen is used for intermediate replacement under the conditions of 350°C and 2MPa, and the material in the dead space of the bed is purged out for 2 minutes;

[0041] After the intermediate replacement process is completed, desorption is carried out by combining vacuum pumping and water vapor purging. Purging and desorption is carried out under the conditions of 350 ° C and 0.08 MPa to desorb the n-alkanes adsorbed in the mordenite. The time is 8 minutes. The content of n-alkanes in the attached oil is 99.1%, and the ethylene yield is 41.6% when used as ethylene cracki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com