Water-based shoes with natural color toe cloth adhesive and preparation method thereof

A technology for adhesives and shoes, applied in the direction of conductive adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low initial adhesive strength, high cost, and long processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

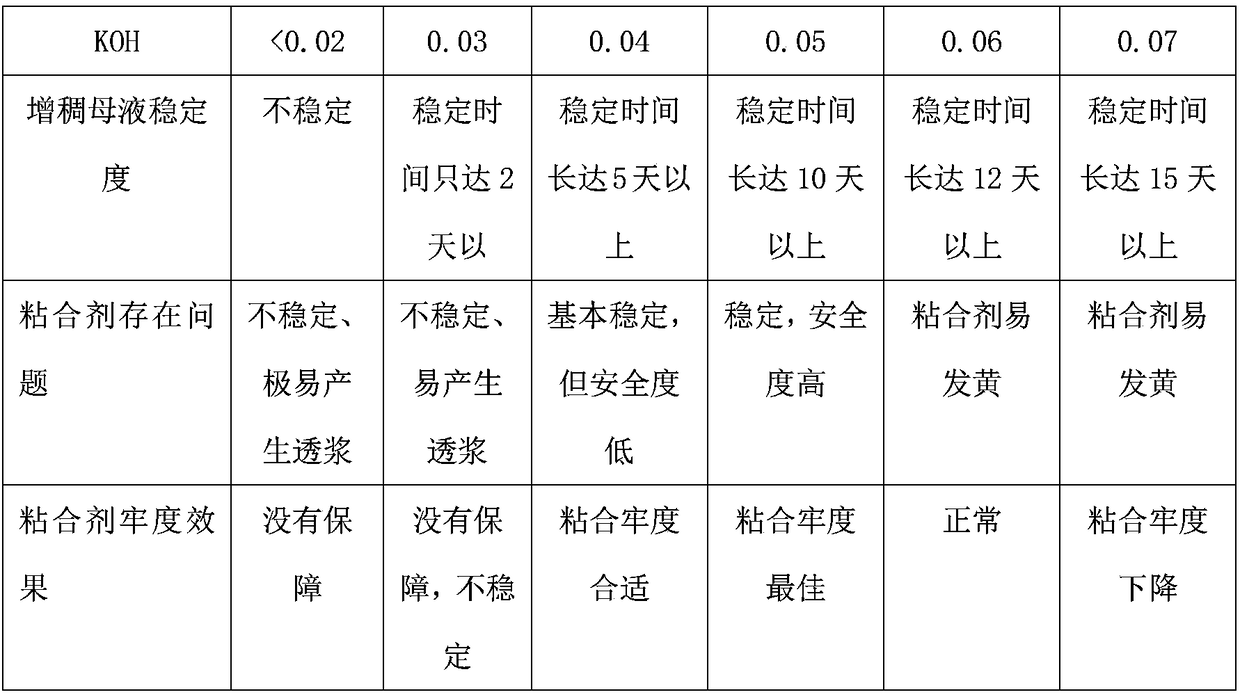

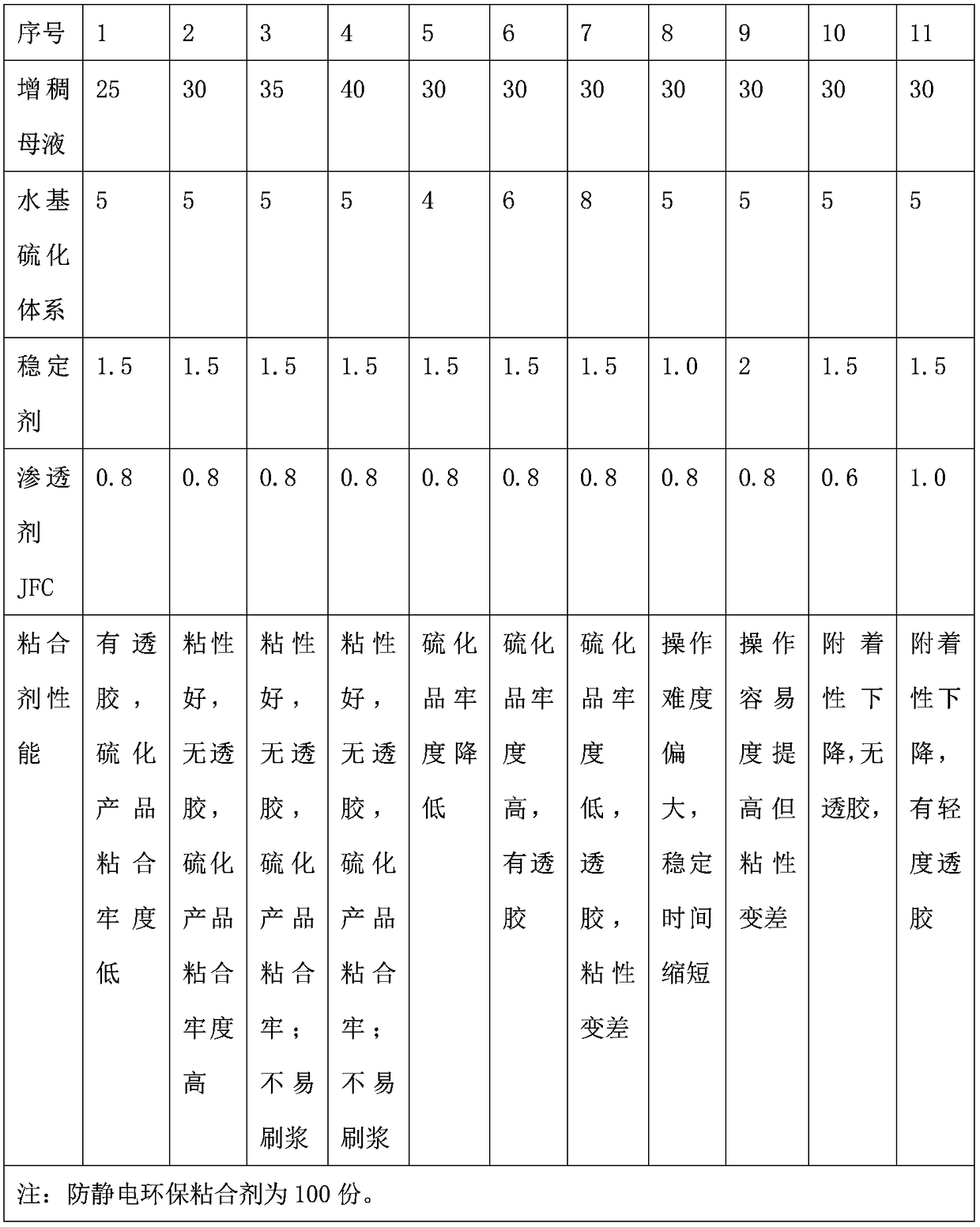

[0051] Embodiments of the present invention: water-based shoes with natural color headband adhesive, calculated in parts by weight, it includes 100 parts of antistatic environmental protection adhesive, 30 parts of thickening mother liquor, 1.5 parts of Pingpingjiao, water-based vulcanization system 5 parts and 0.8 parts of penetrant JFC are raw materials for preparation; every 20 parts of water-based vulcanization system includes 1 part of potassium hydroxide, 1 part of sulfur, 1.5 parts of vulcanization accelerator TMTD, 1.2 parts of nano-zinc oxide, 0.5 parts of diffusing agent, 0.3 parts Anti-aging agent MB, 0.5 parts of anti-aging agent SP-C, 0.5 parts of casein anhydride and 13.5 parts of soft water; every 30 parts of thickening mother liquor consists of 28 parts of soft water, 1.8 parts of sodium carboxymethylcellulose, 0.1 part of anti-mold agent BCM and 0.1 part hydrogen potassium hydride composition.

[0052] The preparation method of the natural-color headband adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com