Anti-irradiation easy-decontamination paint and preparation method thereof

A technology that is easy to decontaminate and is resistant to radiation. It is used in anti-fouling/underwater coatings, radiation-absorbing coatings, anti-corrosion coatings, etc., which can solve the problem of increased waste liquid treatment burden, prone to chalking of coatings, and high requirements for coating performance. problem, to achieve the effects of strong self-cleaning, improved radiation resistance, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

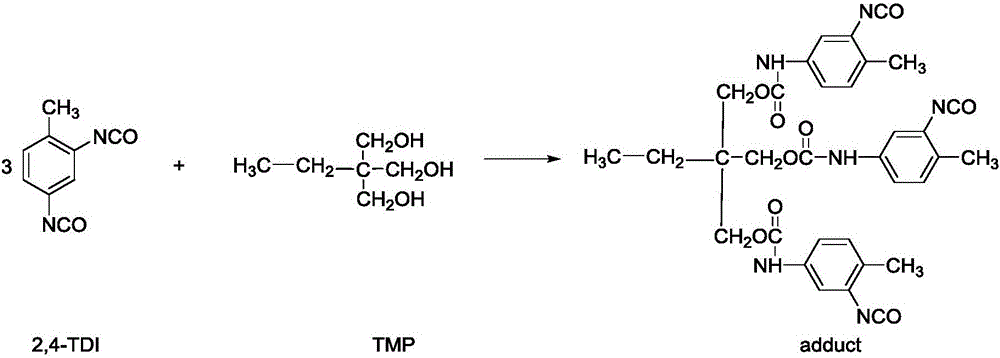

Method used

Image

Examples

preparation example Construction

[0029] Preparation of component A: (1) Weigh the fluorocarbon resin and diluent of the formula into the container, stir evenly to form a transparent solution;

[0030] (2) Add coloring pigments, fillers, anti-corrosion pigments, flame retardants, and dispersants in the formulated amount and stir for 15 minutes;

[0031] (3) Grinding the solution obtained in step (2), and after the fineness of the grinding slurry is less than or equal to 35 μm, transfer the slurry into a stirring container and continue stirring for 30 minutes to obtain component A;

[0032] Preparation of component B: filter the modified aromatic polyisocyanate curing agent and / or aliphatic polyisocyanate curing agent to obtain component B;

[0033] Mixing: Mixing component A and component B in proportion is a radiation-resistant, easy-to-stain paint.

Embodiment 1-5

[0036] (1) Preparation of component A

[0037] ① Prepare each component according to the following ratio

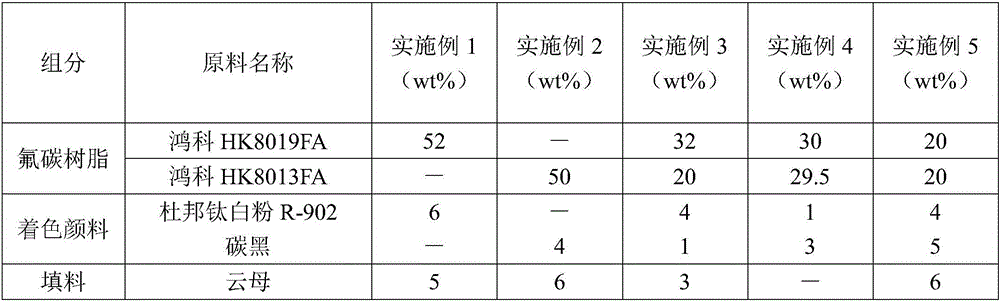

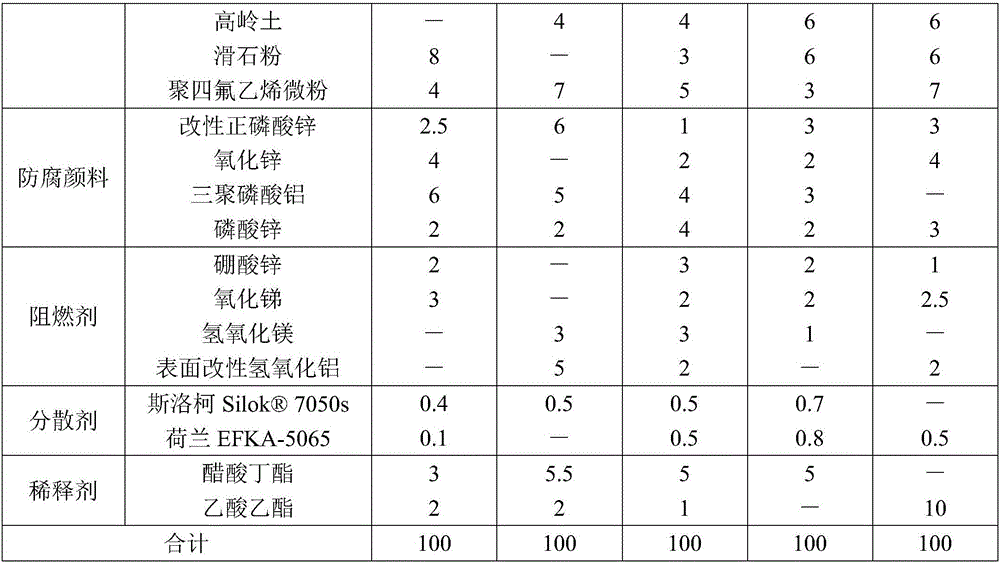

[0038] In terms of weight percentage, component A includes the following components: 40-60% fluorocarbon resin, 4-10% colored pigment, 15-25% filler, 10-15% anti-corrosion pigment, 5-15% flame retardant, Dispersion aid 0.5-1.5%, diluent 5-10%.

[0039] The specific formula in each embodiment is shown in Table 1.

[0040] The formula of A component in each embodiment of table 1

[0041]

[0042]

[0043] ②Specific operation: Add fluorocarbon resin and diluent into the mixing tank, stir until a uniform transparent liquid is formed, then add coloring pigment, filler, anti-corrosion pigment, flame retardant, and dispersing aid in sequence and continue stirring for 15 minutes, then transfer to sand When the fineness of the grinding slurry is less than or equal to 35 μm, transfer the grinding slurry into the mixing tank, and after stirring for 30 minutes, take a sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com