A kind of cyanate-based resin modified phenolic resin foam preparation method

A technology based on phenolic resin foam and phenolic resin, which is applied in the field of resin foam preparation, can solve the problems of limited application range and high thermal conductivity, and achieve the effects of good heat resistance, low thermal conductivity and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

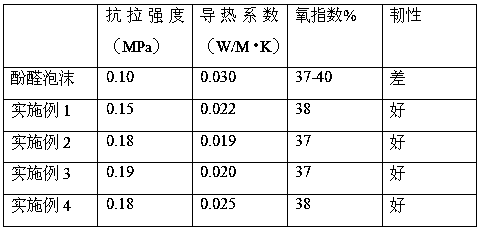

Examples

Embodiment 1

[0025] The present invention is a phenolic resin foam modified by cyanate-based resin and a preparation method thereof, comprising the following steps:

[0026] (1) Set the temperature of the water bath at about 60°C, add 100 parts of phenol into a three-necked flask equipped with a thermometer and a magnetic rotor, then add 1 part of sodium hydroxide and stir evenly for about 5 minutes to activate the phenol, and then divide into batches Add 40 parts of paraformaldehyde, control the addition within half an hour, and keep warm for half an hour after all the addition is completed to make the paraformaldehyde fully react. After fully reacting, gradually increase the temperature to 90°C, keep the constant temperature for about one and a half hours, use acetic acid to adjust the pH to 7-8, and cool the synthesized phenolic resin for 24 hours to obtain the basic expandable phenolic resin.

[0027] (2) Add 10 parts of Span and 8 parts of n-pentane to 100 parts of the expandable phen...

Embodiment 2

[0029] The present invention is a phenolic resin foam modified by cyanate-based resin and a preparation method thereof, comprising the following steps:

[0030] (1) Set the temperature of the water bath at about 60°C, add 100 parts of phenol into a three-necked flask equipped with a thermometer and a magnetic rotor, then add 1 part of sodium hydroxide and stir evenly for about 5 minutes to activate the phenol, and then divide into batches Add 50 parts of paraformaldehyde, control the addition within half an hour, and keep warm for half an hour after all the addition is completed to make the paraformaldehyde fully react. After fully reacting, gradually increase the temperature to 90°C, keep the constant temperature for about one and a half hours, use acetic acid to adjust the pH to 7-8, and cool the synthesized phenolic resin for 24 hours to obtain the basic expandable phenolic resin.

[0031] (2) Add 8 parts of Tween-80 and 10 parts of n-pentane to 100 parts of the expandable ...

Embodiment 3

[0033] The present invention is a phenolic resin foam modified by cyanate-based resin and a preparation method thereof, comprising the following steps:

[0034] (1) Set the temperature of the water bath at about 60°C, add 100 parts of phenol into a three-necked flask equipped with a thermometer and a magnetic rotor, then add 1 part of sodium hydroxide and stir evenly for about 5 minutes to activate the phenol, and then divide into batches Add 45 parts of paraformaldehyde, control the addition within half an hour, and keep warm for half an hour after all the addition is completed to make the paraformaldehyde fully react. After fully reacting, gradually increase the temperature to 90°C, keep the constant temperature for about one and a half hours, use acetic acid to adjust the pH to 7-8, and cool the synthesized phenolic resin for 24 hours to obtain the basic expandable phenolic resin.

[0035] (2) Add 10 parts of Tween-80 and 88 parts of n-pentane to 100 parts of the expandable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com