Composite car roof

A technology for composite materials and automobile roofs, which is applied to vehicle parts, upper structure sub-assemblies, chemical instruments and methods, etc., can solve the problems of increased roof layout space, local rigidity surplus, and cost rise, so as to ensure quality and Appearance, simplify the preparation and assembly process, achieve the effect of thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

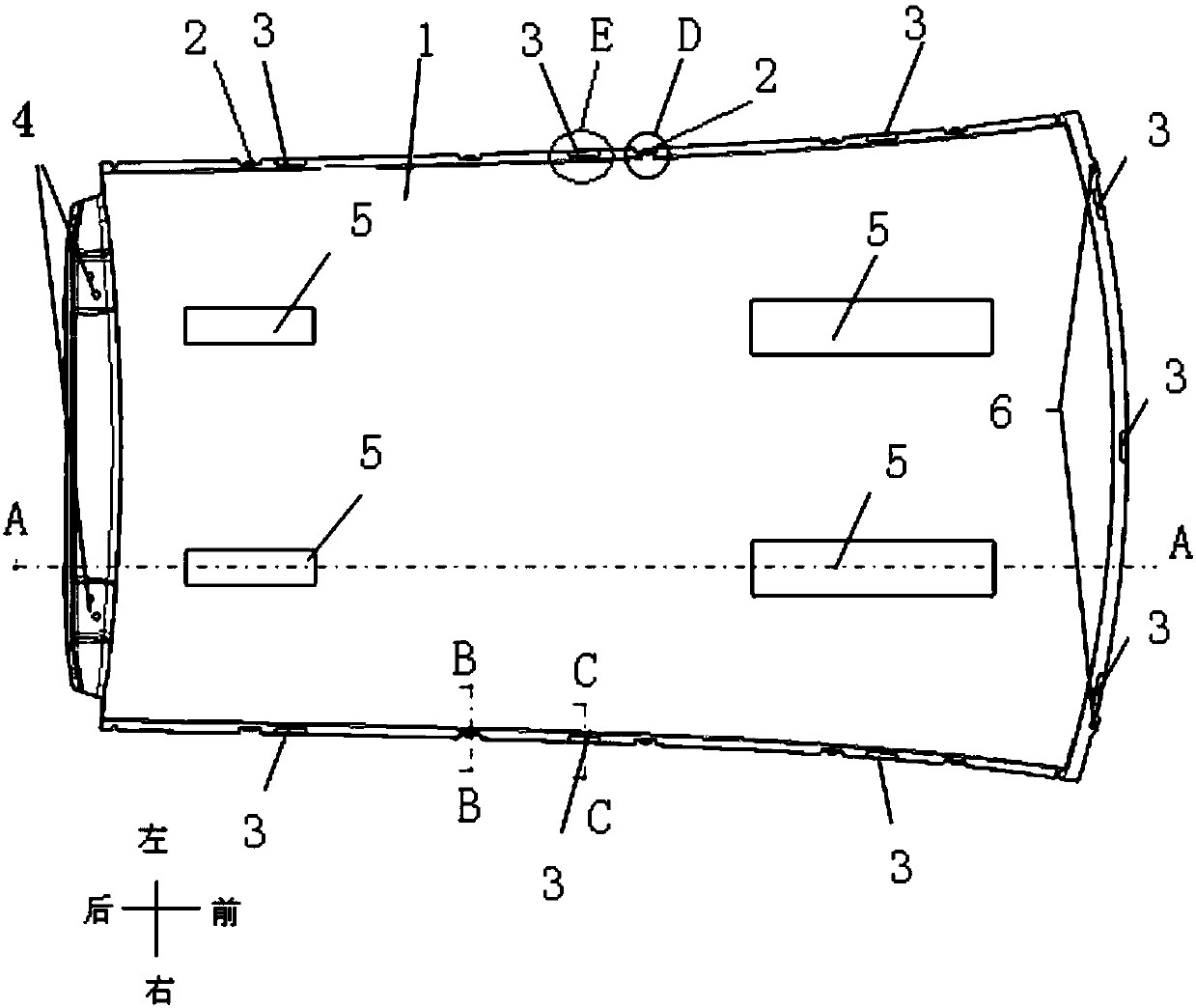

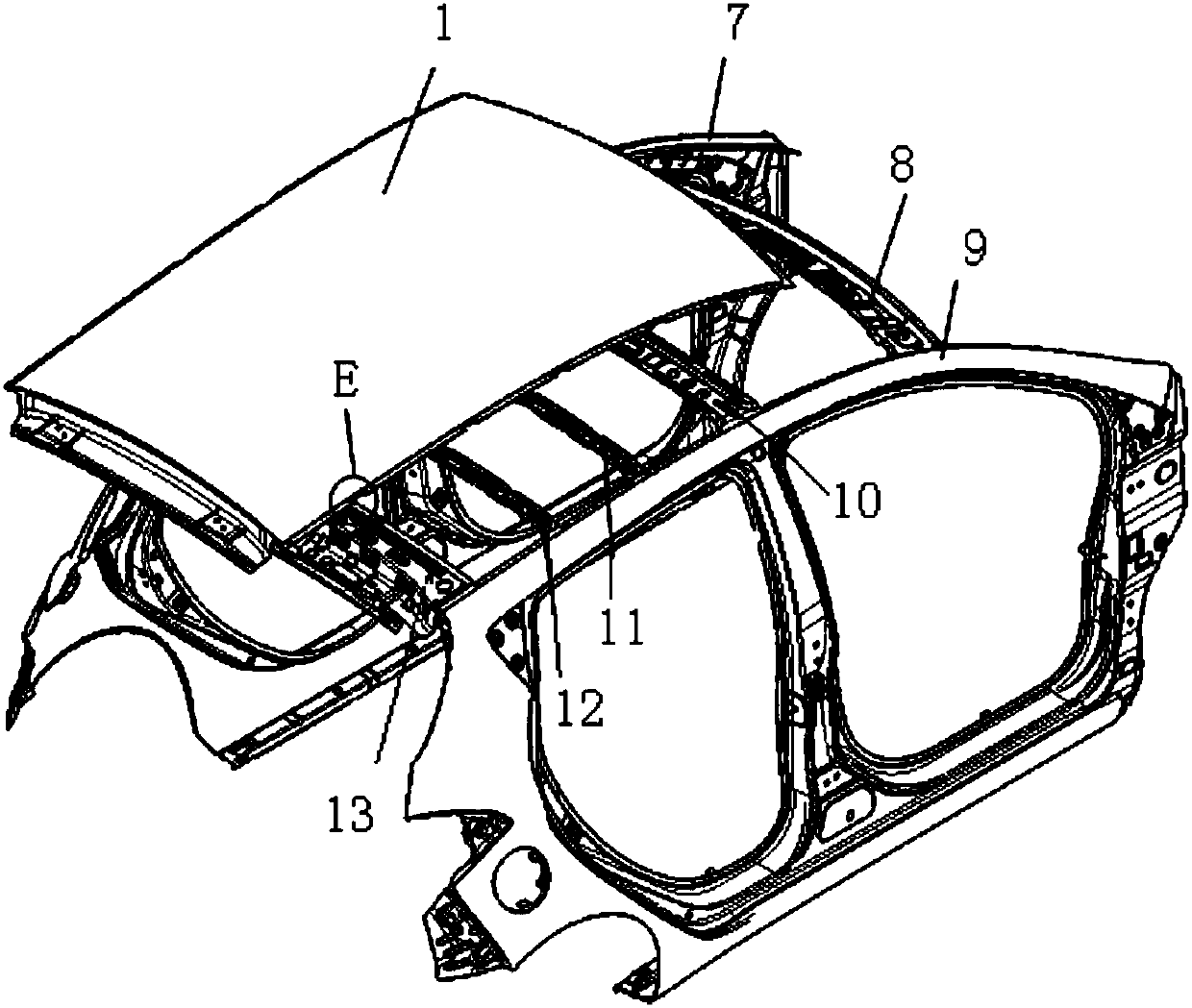

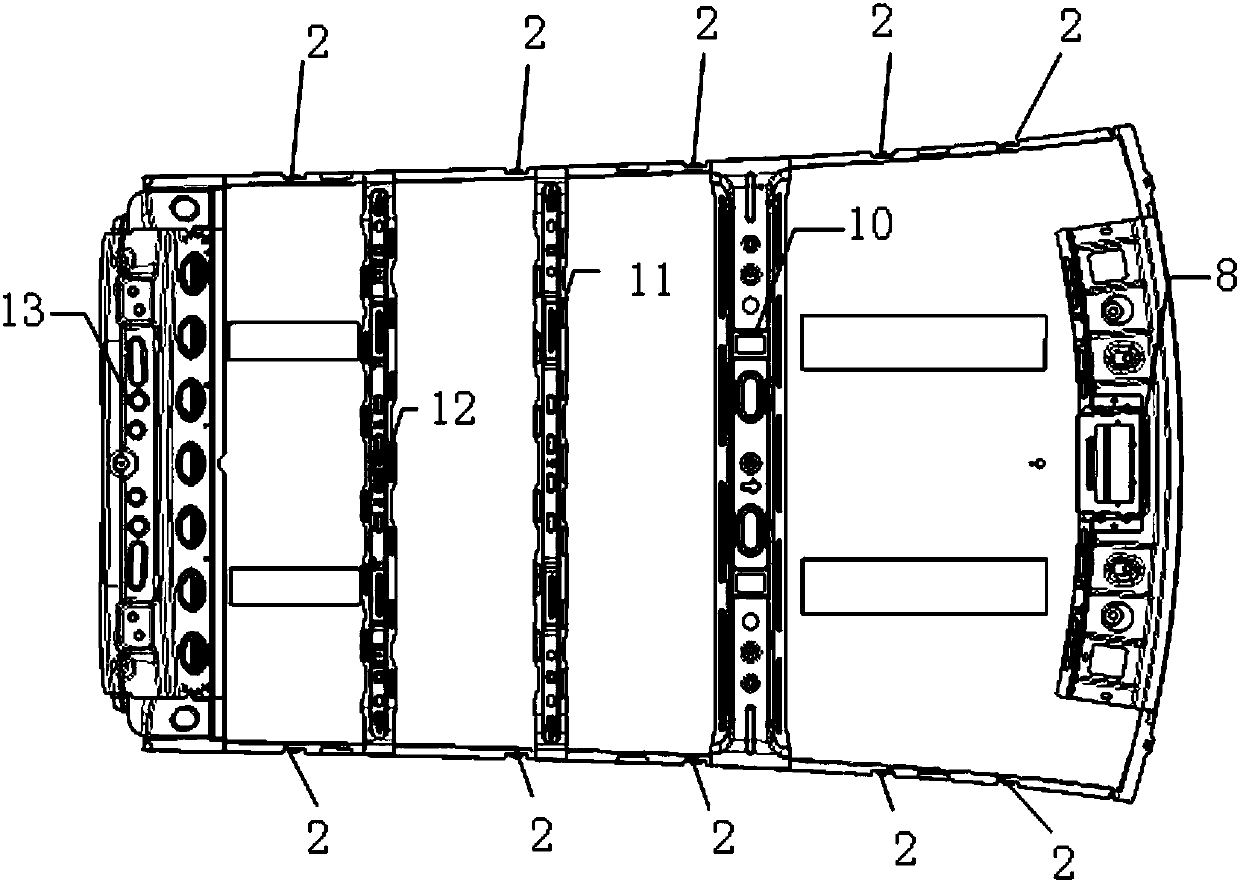

[0032] Such as Figure 1 to Figure 10 The composite car roof shown includes a roof main body 1, a front windshield mounting hole 6 is provided on the front edge of the roof main body 1, and a hinge mounting hole 4 is provided on the rear edge of the roof main body 1. The top cover main body 1 sequentially includes an inner layer 16, an intermediate layer 15 and an outer layer 14 from the inside to the outside, and the layers are formed by compression molding. The outer layer 14 is made of carbon fiber composite material, so that the top cover not only meets the requirement of light weight, but also has the texture of carbon fiber cloth, which improves the appearance quality. The middle layer 15 is made of glass fiber composite material; it can reduce the weight of the top cover. The inner layer 16 is made of glass fiber composite material, which can reduce the weight of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap