Method for preparing and using fiber-reinforced hat-shaped rib molding soft mold

A fiber-reinforced, forming mold technology, applied in the field of composite material forming, can solve the problems of Airpad rubber soft mold being time-consuming and laborious, having to be re-prepared in time, prone to breakage, etc., to avoid breakage problems, improve reusability, and facilitate The effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

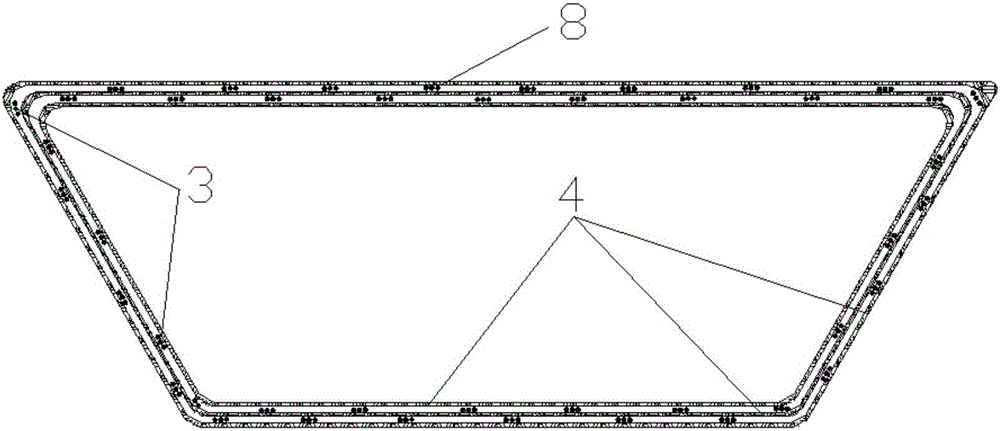

[0023] according to figure 1 The inner profile surface 1 of the "cap" rib shown in the figure is designed in the soft molding mold 2 of the "hat" rib, and the unvulcanized rubber matrix 3 and the unidirectional fiber reinforcement 4 adopt the sandwich blending method, and the "hat" rib Lay 3 layers of unvulcanized rubber 3 in the molding die 2 of the strip soft mold, and lay unidirectional carbon fiber reinforcements with a width of 3 mm and a length of 200 mm on the surface of the unvulcanized rubber 3 at intervals of 10 mm. The length and direction of the hat-shaped ribs are consistent, and the unidirectional carbon fiber reinforcements are spliced along the 0° direction. Lay 2 layers of unvulcanized rubber 3, such as Image 6 As shown, after encapsulation, vacuuming, and vulcanization, a carbon fiber-reinforced "cap" type rib forming soft mold 5 is obtained;

[0024] Put the "cap" type reinforced composite wall panel structure preform 6 between the rigid female mold 7 a...

Embodiment 2

[0026] according to figure 1 The inner profile surface 1 of the "cap" rib shown in the figure is designed in the soft molding mold 2 of the "hat" rib, and the unvulcanized rubber matrix 3 and the unidirectional fiber reinforcement 4 are interlayer blended. A layer of unvulcanized rubber 3 is laid in the strip soft mold forming mold 2, and unidirectional glass fiber reinforcements with a width of 3 mm are laid on the surface of the unvulcanized rubber 3 at intervals of 15 mm. The length and direction of the "shaped ribs are consistent, and the unidirectional glass fiber reinforcements are spliced along the 0° direction. The non-collinear unidirectional glass fiber reinforcements are not spliced at the same cross-sectional position of the "cap" rib forming soft mold 5, and then Lay a layer of unvulcanized rubber 3, and then lay unidirectional glass fiber reinforcements with a width of 3 mm on the surface of the unvulcanized rubber 3 at intervals of 10 mm and interlaced with ...

Embodiment 3

[0029] according to figure 1The inner profile surface 1 of the "cap" rib shown in the figure is designed in the soft molding mold 2 of the "hat" rib, and the unvulcanized rubber matrix 3 and the unidirectional fiber reinforcement 4 adopt the sandwich blending method, and the "hat" rib Lay two layers of unvulcanized rubber 3 in the molding die 2 of the strip soft mold, and lay unidirectional aramid fiber reinforcements with a width of 5 mm on the surface of the unvulcanized rubber 3 at intervals of 20 mm. The 0° direction of the unidirectional aramid fiber reinforcement is The length and direction of the "hat" ribs are consistent, and the unidirectional aramid fiber reinforcement is spliced along the 0° direction, and the non-collinear unidirectional aramid fiber reinforcement is not in the same cross-sectional position of the "hat" rib forming soft mold 5 Splicing, and then laying two layers of unvulcanized rubber 3, packaging, vacuuming, and vulcanization to obtain aramid f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com