High-specific-surface-area N-doped surface-modified silkworm excrement-based microporous carbon material and preparation method and application thereof

A high specific surface and surface modification technology, applied in the field of carbon materials, can solve the problems of excessive pesticide residues in agricultural products, non-target biological damage to the environment, and low efficiency of pesticide utilization, etc., to achieve good slow and controlled release, high specific surface area, and improved porosity The effect of rate and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

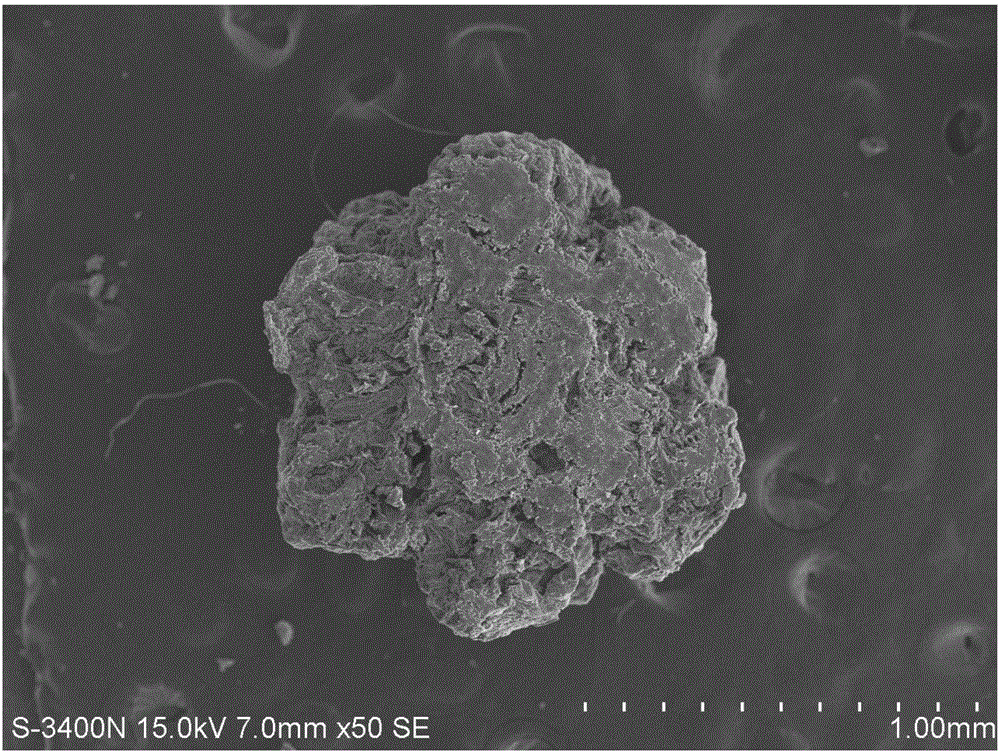

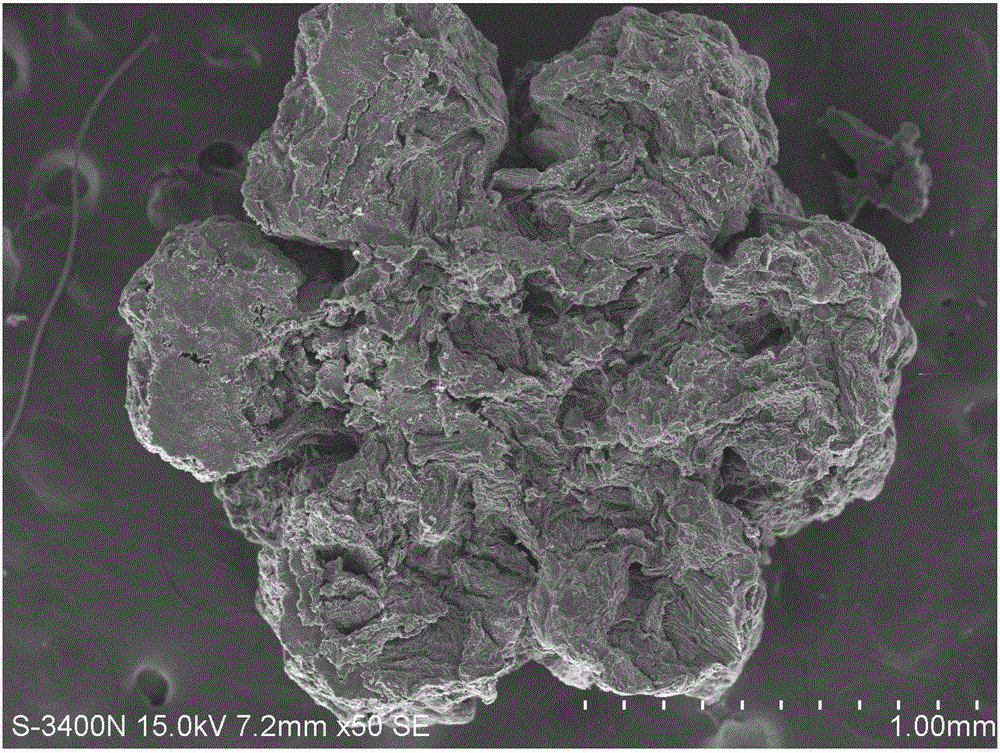

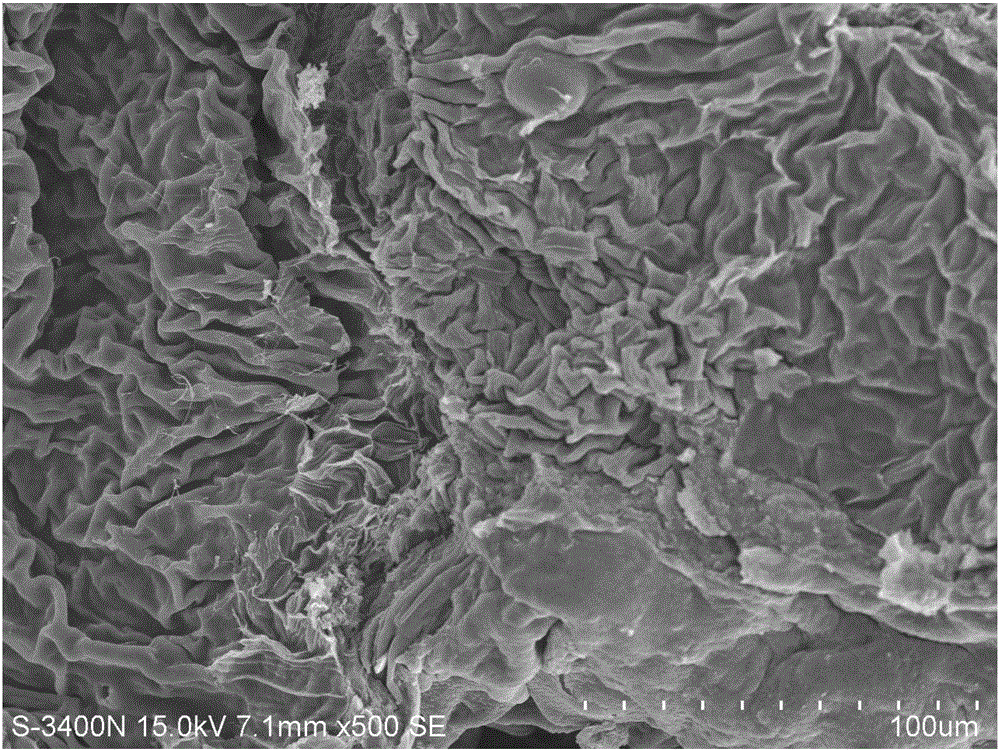

Image

Examples

Embodiment 1

[0034] A method for preparing a high specific surface N-doped surface-modified silkworm excrement-based microporous carbon material, comprising the following steps,

[0035] (1) Mix and swell the original silkworm excrement and deionized water according to the mass-to-body ratio of 1:100. After swelling at 30°C for 3.0 hours, remove the silkworm excrement and freeze-dry it. First, freeze and pretreat at -20°C for 4 hours. Then lower the temperature to -60° C. and freeze-dry for 24 hours to obtain freeze-dried silkworm excrement.

[0036] in N 2 In the atmosphere, 10.0 g of freeze-dried silkworm excrement was raised to 700°C at a heating rate of 5°C / min, kept at 700°C for more than 3 hours, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0037] (2) Mix carbonized silkworm excrement and KOH at a mass ratio of 1:1, 2 In the atmosphere, the temperature was raised to 650°C at a rate of 5°C / min, and kept at 650°C for 5.0h to carry out the pore expan...

Embodiment 2

[0040] (1) Mix and swell the original silkworm excrement and deionized water according to the mass-to-body ratio of 1:120. After swelling at 35°C for 2.5 hours, remove the silkworm excrement and freeze-dry it. First, freeze it at -20°C for 3 hours. Then lower the temperature to -55° C. and freeze-dry for 36 hours to obtain freeze-dried silkworm excrement.

[0041] In an Ar atmosphere, 10.0 g of freeze-dried silkworm excrement was raised to 800°C at a heating rate of 5°C / min, kept at 800°C for more than 2.5h, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0042] (2) Mix carbonized silkworm excrement and KOH at a mass ratio of 1:2, 2 In the atmosphere, the temperature was raised to 750°C at a rate of 5°C / min, and kept at 750°C for 4.0h to carry out the pore expansion reaction. After cooling down to room temperature naturally, the obtained solid was dissolved in 1mol / L HCl to wash and dissolve KOH. Then use deionized water to wash to pH ≈ 7, cent...

Embodiment 3

[0045] (1) Mix and swell the original silkworm excrement and deionized water according to the plastid ratio of 1:140, swell at 40°C for 2.0 hours, remove the silkworm excrement and freeze-dry it, and first freeze and pretreat it at -25°C for 2 hours, Then lower the temperature to -50° C. and freeze-dry for 48 hours to obtain freeze-dried silkworm excrement.

[0046] in N 2 In the atmosphere, 10.0 g of freeze-dried silkworm excrement was raised to 850°C at a heating rate of 5°C / min, kept at 850°C for more than 2.0 hours, and then cooled to room temperature to prepare carbonized silkworm excrement.

[0047] (2) Mix carbonized silkworm excrement and KOH at a mass ratio of 1:3, 2 In the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min, and kept at 800°C for 3.0h to carry out the pore expansion reaction. After cooling down to room temperature naturally, the obtained solid was dissolved in 1mol / L HCl to wash and dissolve KOH. Then use deionized water to wash to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com