Bread maker control system, device and method

A control system and control device technology, which is applied in the direction of toasting equipment, kitchen utensils, household utensils, etc., to shorten the kneading time and fermentation time, improve the production efficiency and bread quality, and improve the production efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

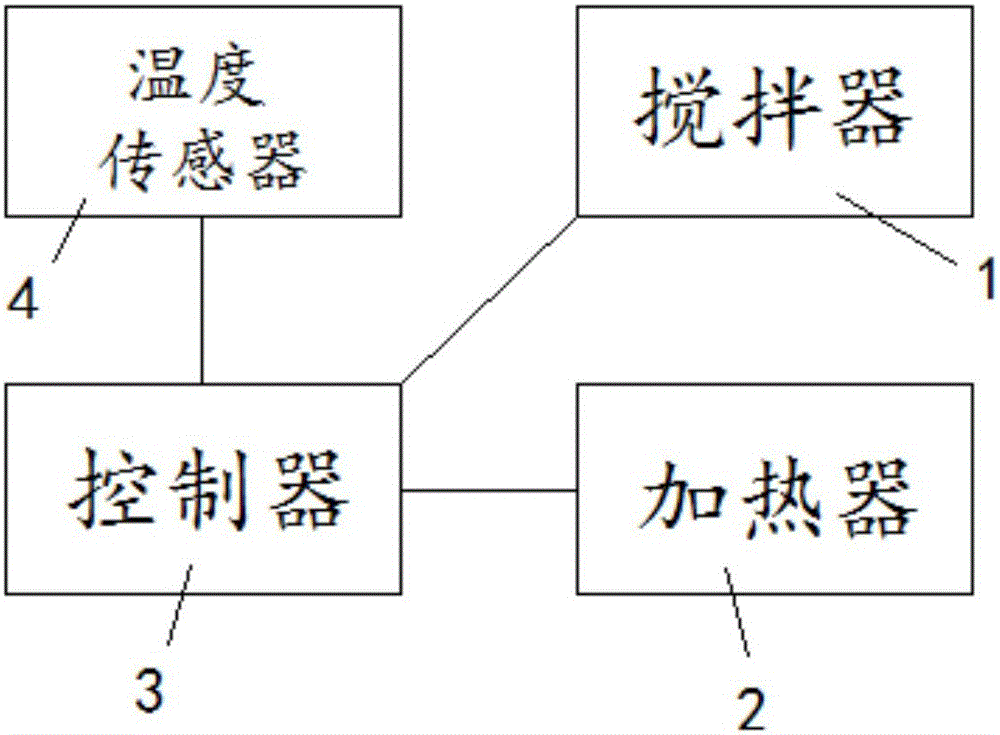

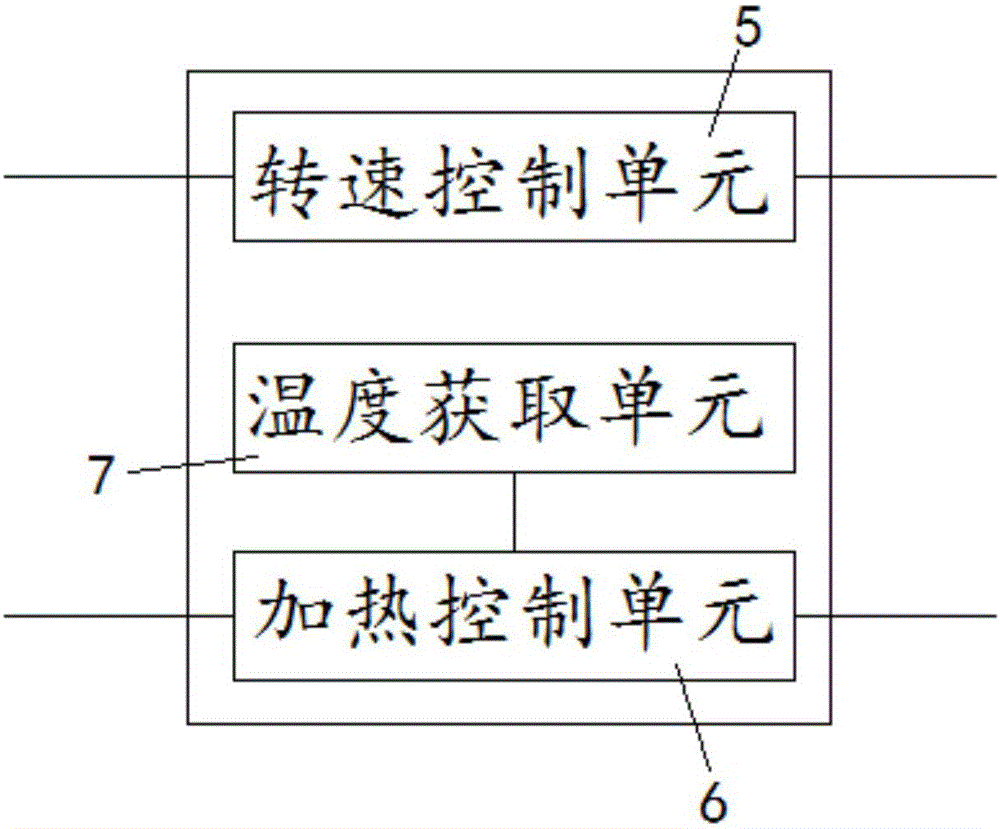

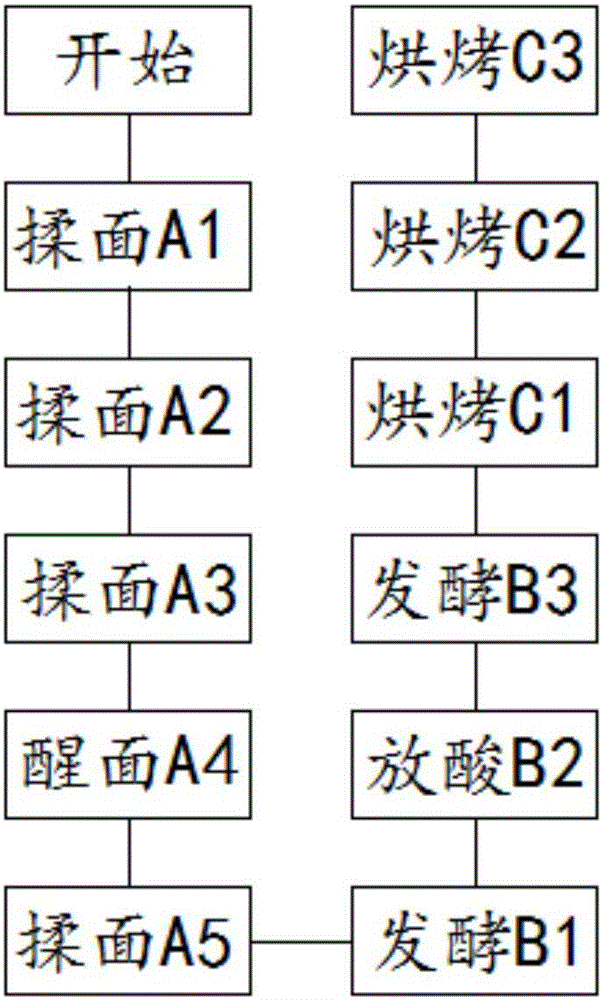

[0056] like figure 1 As shown, a control system for a bread machine according to the present invention includes: a mixer 1, which is used to stir the dough at a predetermined speed; a heater 2, which is used to change the temperature of the dough; and a controller 3, which is used to control all the agitator 1 and the heater 2, and the controller 3 is used to control the agitator 1 to operate at a plurality of different predetermined rotational speeds and a plurality of predetermined stirring durations corresponding to the plurality of different predetermined rotational speeds The dough is stirred, and the heater 2 is used to control the heater 2 to heat the dough according to a plurality of different predetermined heating temperatures and a plurality of predetermined heating time periods corresponding to the plurality of different predetermined heating temperatures. Through the combination of various kneading speeds and durations, the kneading process can simulate the manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com