Heat-conduction double-sided bonded graphite flake

A thermal conductivity, graphite sheet technology, applied in the field of thermal conductivity double-sided bonded graphite sheets, can solve the problems of uneven quality and performance of polyimide film products, affecting the heat dissipation performance of double-sided film for heat dissipation, and unstable product heat dissipation performance. , to avoid volume shrinkage, improve thermal conductivity, improve compactness and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

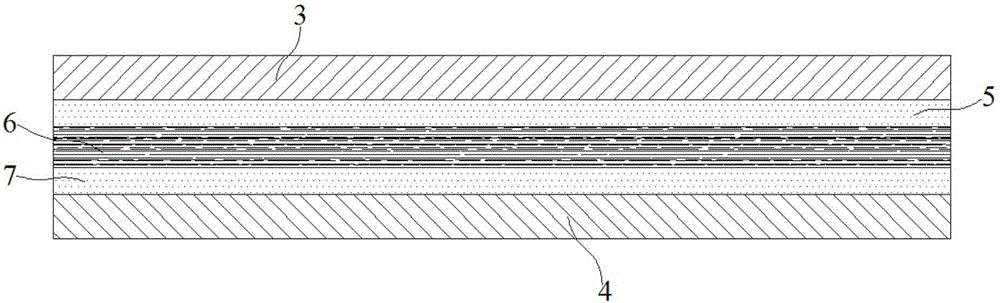

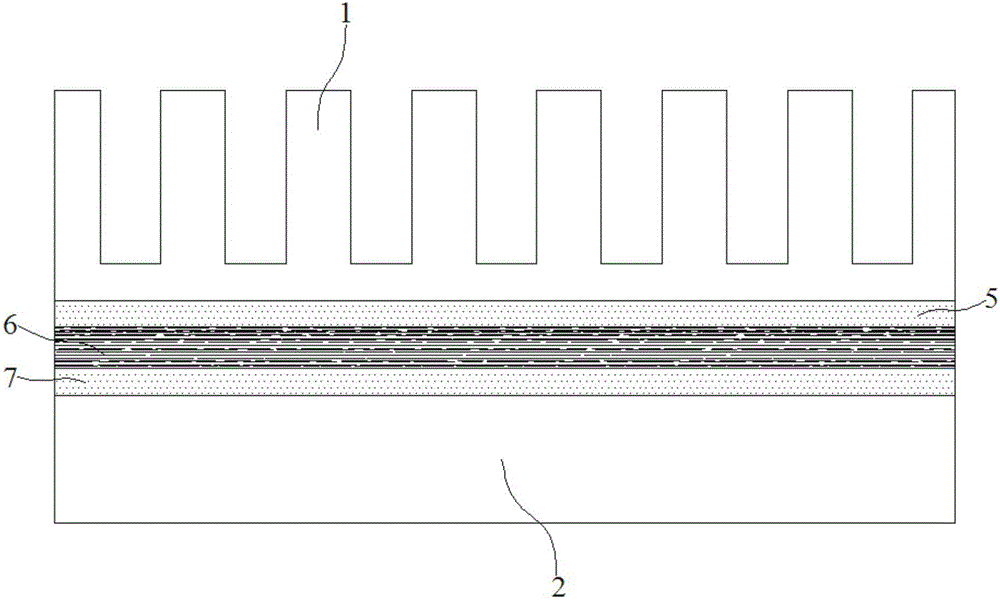

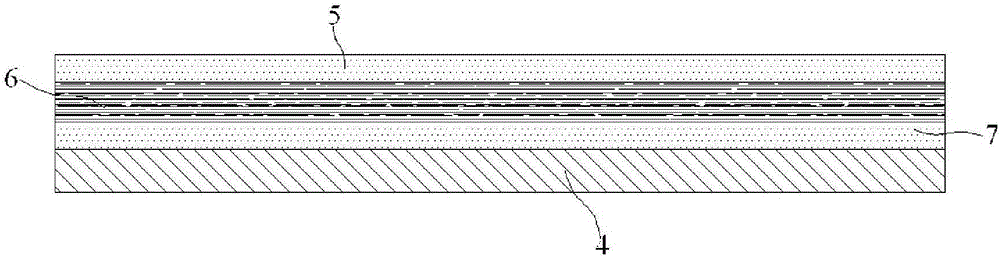

[0024] Embodiment: A thermally conductive double-sided bonded graphite sheet, the thermally conductive double-sided bonded graphite sheet is attached between the heat sink 1 and the heating component 2, and the thermally conductive double-sided bonded graphite sheet includes light peeling Type PET film 3 and heavy peeling type PET film 4, between the light peeling type PET film 3 and heavy peeling type PET film 4, a first thermally conductive adhesive layer 5, a graphite layer 6 and a second thermally conductive adhesive layer 7 are arranged in sequence ; The graphite layer 6 is obtained by the following process, which process comprises the following steps:

[0025] Step 1. Raise the polyimide film from room temperature to 250°C at a speed of 4~6°C / min, keep it for 0.9~1.1 hours, then raise it to 400°C at a speed of 2.5~3.5°C / min, keep it for 1 hour and then lower it. to room temperature;

[0026] Step 2, on the upper and lower surfaces of the polyimide film through step 1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com