A permanent magnet positioning tool for surface-mounted permanent magnet motor

A permanent magnet motor, positioning tooling technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of complex processing technology, inaccurate installation, large electromagnetic force, etc., to simplify the processing technology and ensure positioning accuracy. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

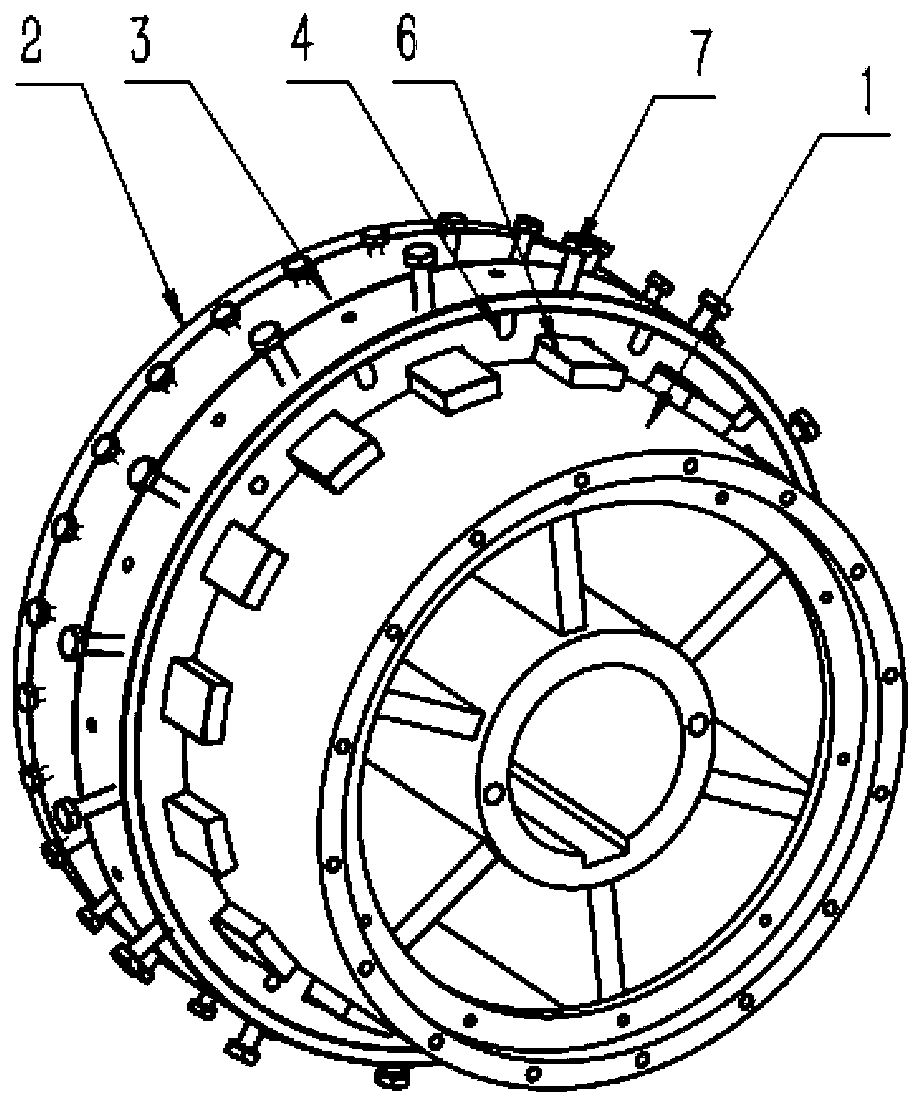

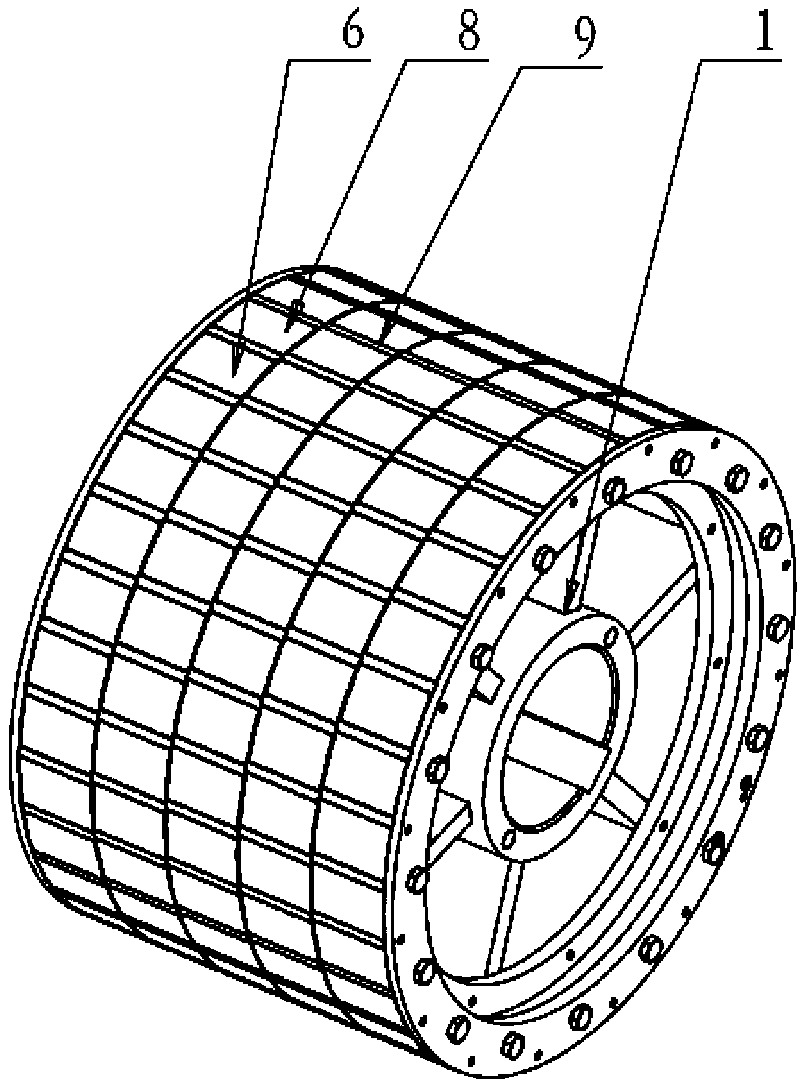

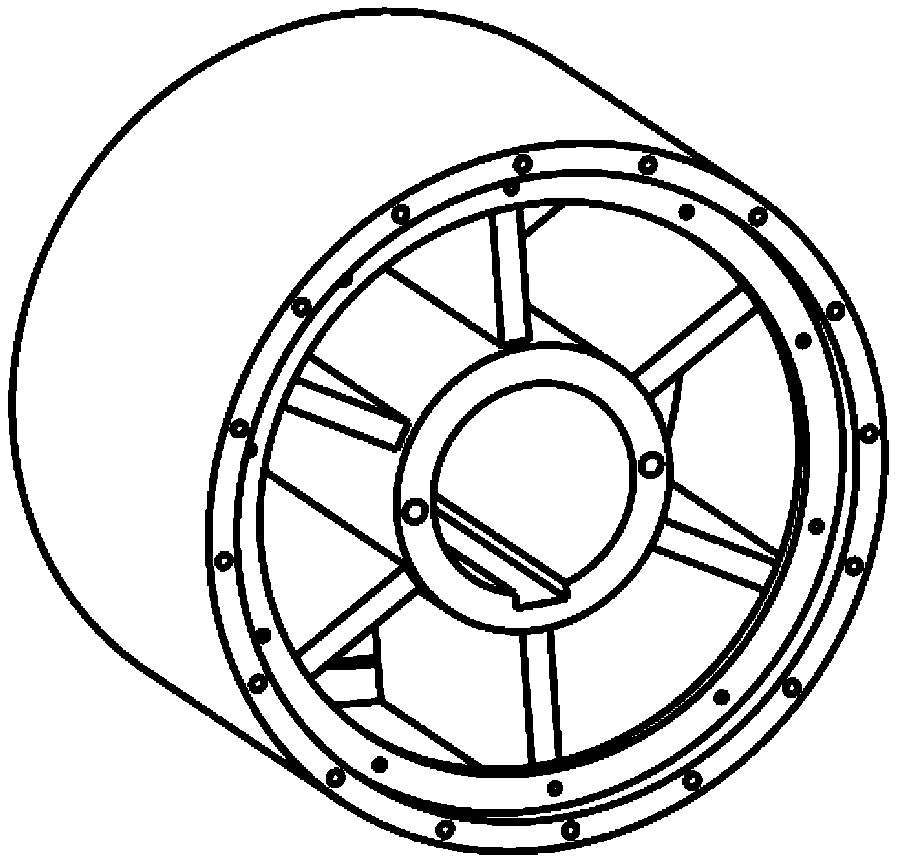

[0026] refer to figure 1 Shown is the general drawing of the permanent magnet installation tooling, which includes a cylindrical skeleton 1 with openings at both ends. The skeleton 1 is an ordinary carbon steel skeleton, a silicon steel skeleton or other magnetic material skeletons. The inside of the skeleton 1 A plurality of reinforcing ribs are also arranged according to the law, and coaxial axial positioning plates 2, radial positioning rings 3 and tangential positioning rings 4 are successively arranged on the outer circumference of the skeleton 1, and the axial positioning plates 2 and the skeleton 1 is provided with a first positioning member, wherein the first positioning member is a bolt, a pin or a spring pressure rod, and the axial positioning plate 2 is provided with a first outer stop 21, a first inner stop 22 and a second A positioning hole 23, the radial positioning ring 3 is provided with a second positioning hole 31, a second inner stop 34 and a second outer st...

Embodiment 2

[0039] The difference from Example 1 is that the frame 1 is not made of steel plates, but laminated with silicon steel sheets.

Embodiment 3

[0041] The difference from Example 1 is that the permanent magnets are not segmented in the axial direction, and limited by the processing technology, the length of the common permanent magnets at present is difficult to exceed 60 mm. If the permanent magnets with a length of more than 60 mm are required, the axial segment is mostly used. If the length is less than 60mm, the axial non-segmented method is adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com