Hydraulic valve element milling clamping fixture

A technology for clamping tooling and hydraulic valve, which is applied in the field of tooling and hydraulic valve core milling and clamping tooling, which can solve the problems of high labor intensity, low processing efficiency, and adverse effects on positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

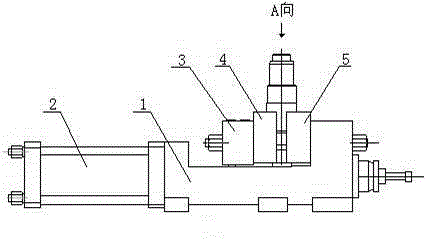

[0015] The hydraulic spool milling and clamping tool of this embodiment is as follows: figure 1 As shown, the base 1 for placing on the milling machine is in a concave shape, and one end is equipped with a hydraulic cylinder 2 installed horizontally, and the piston rod protruding from the hydraulic cylinder 2 is fixedly connected with the push block 3 . The bottom of the pushing block 3 is installed in the chute in the middle of the base 1 to form a horizontal movement pair, and is fixedly connected with the dynamic clamping block 4 by means of fasteners. The opposite side of the dynamic clamping block 4 is equipped with a static clamping block 5 fixed on the other end of the base 1 .

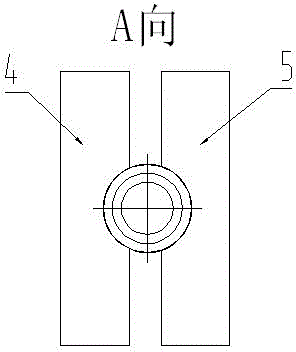

[0016] Such as figure 2 As shown, the middle parts of the opposite end surfaces of the dynamic clamping block 4 and the static clamping block 5 respectively have workpiece positioning circular arc concaves matching the outer circle of the valve core G. The positioning arc concave of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com