Preparation method of diaphragm and lithium ion battery

A lithium-ion battery and separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as affecting battery performance, easy falling off of ceramic layers, and restricting large-scale applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

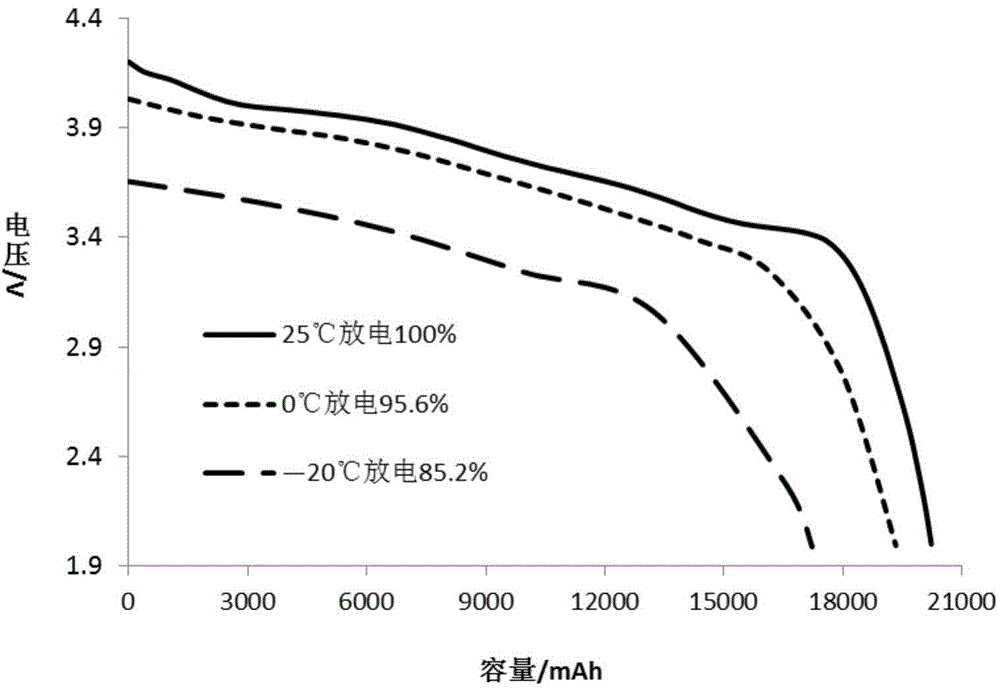

[0024] like figure 1 The preparation method of the shown diaphragm comprises the following steps:

[0025] S10. Coating the ceramic material on both surfaces of the organic substrate by physical vapor deposition technology to obtain a diaphragm, the diaphragm is an organic diaphragm coated with a ceramic material, and the physical vapor deposition technology is magnetron sputtering, ion beam sputtering, pulsed At least one of laser deposition, atomic layer deposition, and electron beam evaporation.

[0026] The ceramic material is α-Al 2 O 3 (α-alumina), SiO 2 (Silica), TiO 2 (Titanium dioxide), ZrO 2 (zirconia) or BN (boron nitride). Among them, porous α-Al 2 O 3 It has the characteristics of capillary liquid absorption. The surface of the diaphragm is made of ceramic material, which can improve the permeability of the diaphragm at low temperature. At the same time, because the ceramic has a certain strength, the low temperature mechanical properties of the diaphragm ...

Embodiment 1

[0049] α-Al with a particle size of 7nm 2 o 3 Coated on both surfaces of the organic substrate by atomic layer deposition technology, the organic substrate is a PP / PE / PP three-layer composite separator, PE is the middle layer, and both sides are PP.

[0050] LiMn 0.7 Fe 0.3 PO 4 、LiNi 0.8 co 0.15 Al 0.05 o 2 , SP, KS-6, and PVDF were mixed with NMP (N-methylpyrrolidone) according to the mass ratio of 46.45:46.45:2.05:2.05:3 to form a uniform slurry, and then coated on aluminum foil to control the compaction density. 3.0, the density of one side is 110g / cm 2 , dried and rolled to obtain the positive electrode sheet.

[0051] Mix artificial graphite, SP, KS-6, CMC and SBR with deionized water according to the mass ratio of 93.8:1:1:1.7:2.5 to form a uniform slurry, and then coat it on copper foil to control the compaction density is 1.35, and the density of one side is 60g / cm 2 , dried and rolled to form a negative electrode sheet.

[0052] The selected composition i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com