Switch reset buffer structure

A cushioning structure and switch technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of affecting operation comfort and noise, and achieve the effect of improving operation comfort and reducing impact impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

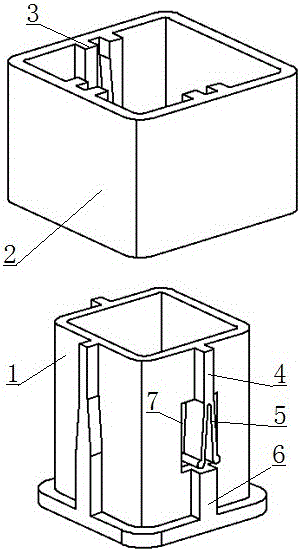

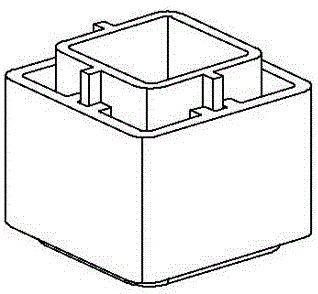

[0018] Embodiment: The switch structure includes a button, a slider 1, a housing 2, an elastic rubber pad, a PCB, and a base. Wherein the reset structure is achieved by the cooperation of two parts, the slider 1 and the housing 2, to achieve the motion deceleration effect.

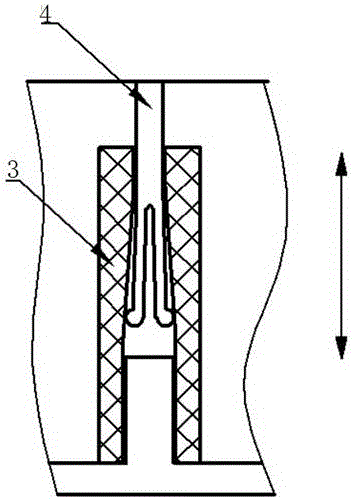

[0019] There is a guide groove 3 on the inner wall of the housing 2, and the guide groove 3 is a three-section type. The guide rib is also a three-section type, including a narrow straight section 4 at the upper end, two elastic cantilevers in the middle section) and a wide straight section 6 at the lower end. There is a rectangular groove 7 on the slider 1, and the elastic cantilever 5 is located in the groove 7. The upper ends of the two elastic cantilevers 5 are fixed, the lower ends are open, and there are convex points at the ends; the guide ribs cooperate with the guide groove 3, and the upper convex point structure of the elastic cantilever 5 on the slider 1 is always in contact with the housing gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com