An alignment system and alignment method for automatic focusing

An automatic focusing and aligning system technology, applied in the photoengraving process, instruments, optics and other directions of the pattern surface, can solve the problems of complex structure, difficult realization, difficult and clear imaging of alignment marks, etc., to achieve rapid focusing, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

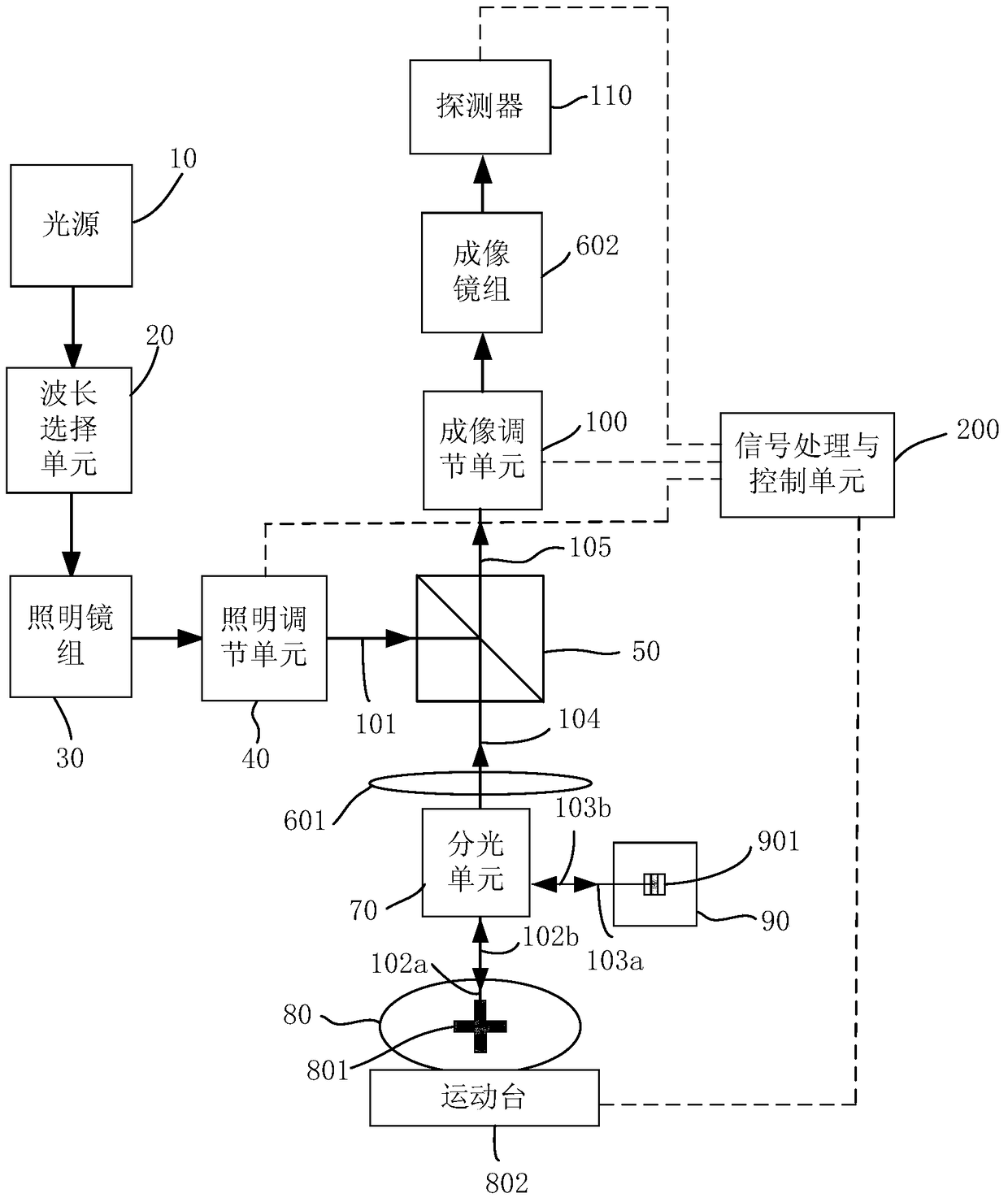

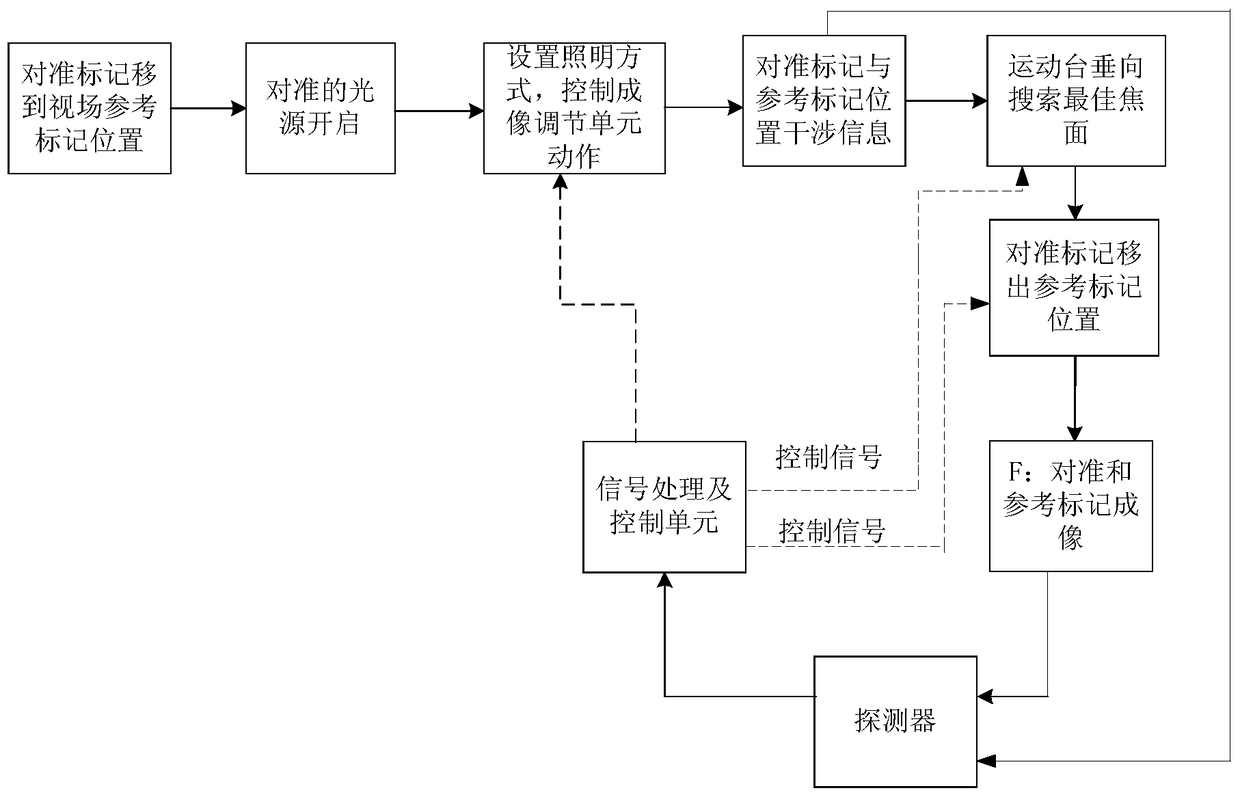

[0043] figure 1 It is a schematic structural diagram of the automatic focusing alignment system provided by the present invention, as shown in the figure, the automatic focusing system at least includes:

[0044] The light source 10 is used to provide an illumination light source;

[0045] A wavelength selection unit 20, configured to filter optical signals with interfering wavelengths or bandwidths;

[0046] The illuminating mirror group 30 is used to provide illuminating light for the alignment marks 801 on the surface of the silicon wafer 80;

[0047] An illumination adjustment unit 40, configured to switch between a manual illumination mode and an automatic illumination mode and adjust light intensity and polarization state distribution, etc. for the marks on the surface of the silicon wafer 80;

[0048] The beam splitting unit 50 is used for vertically distributing and splitting the passing illumination light path and the passing reflection light path;

[0049] The refer...

Embodiment 2

[0074] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the measurement reflected light path 102b is taken as the axis, the first reflected light path 104 and the second reflected light path 105 are coaxial with the measured reflected light path 102b, and the The angle formed by the measurement incident light path 102a and the axis where the measurement reflection light path 102b is located is between 0° and 90°, and this off-axis lighting method can improve contrast and reduce interference. In addition, a shutter 902 is installed on the optical path of the reference mark 901 for switching. After the photolithography of the first silicon wafer, the shutter 902 can be used to close the reference incident light path 103a incident on the reference mark 901. The alignment system can automatically search for the best focal plane position z according to the alignment data records of the first silicon wafer, and at the same time, it can avo...

Embodiment 3

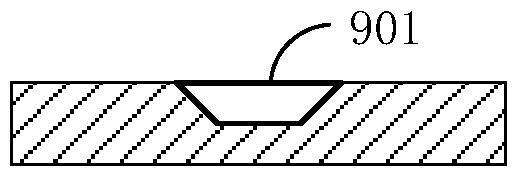

[0076] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the cross-section of the reference mark 901 is an isosceles trapezoid that is convex relative to the reference mark surface 90 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com