A deep-sea long-life electric field sensor

An electric field sensor, deep-sea environment technology, used in instruments, measuring electrical variables, manufacturing measuring instruments, etc., can solve the problems of limited long-term stability of electrodes, easy reduction of stability and sensitivity, internal electrode pollution, etc., and achieve stable electrode stability. Potential, prevent electrode potential drift, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

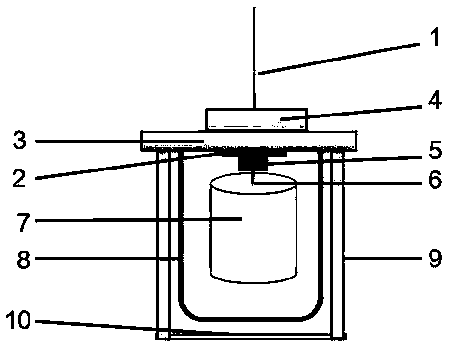

[0021] Embodiment 1: the present invention will be further described below in conjunction with accompanying drawing example:

[0022] combine figure 1 . One end of the electrode lead wire 1 is connected together with the pure silver column 6 embedded in the upper surface of the cylindrical inner electrode core body 7 of silver / silver chloride powder pressing and sintering through the solder joint 5, and the inner electrode core body 7 is placed on The middle part of the electrode sleeve 9 is fixed with epoxy sealing filler 4, and the inner electrode core 7 is required to expose the lower surface, and the remaining surface is sealed with epoxy sealing filler 4; after the other end of the electrode lead 1 passes through the epoxy sealing filler 4 Pass through the upper opening of the electrode sleeve 9 and pass through the through hole of the electrode fixing sealing sleeve 3 to extend outside the main body of the reference electrode as a signal interface for connecting monitor...

Embodiment 2

[0023] Embodiment 2: Preparation of nano-silver chloride powder.

[0024] Pure AgNO will be analyzed at room temperature 3 and NaCl powder in a ball mill at a weight ratio of 1:1.2 for programmed pulverization and ball milling for 50 minutes to obtain nano silver chloride powder.

Embodiment 3

[0025] Example 3: Pressing and calcining the inner electrode core.

[0026] Nano-silver and nano-silver chloride powder are mixed with 2% by mass of binder to granulate according to the weight ratio of 1:1.72, the pressing pressure is 10MPa, and sintering at 210°C after molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com