Gas-fired boiler based on porous medium combustion technology

A technology of porous media and combustion technology, applied in the field of gas boilers, can solve the problems of large volume, high emission, and low thermal efficiency, and achieve the effects of overcoming large volume, reducing combustion temperature, and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

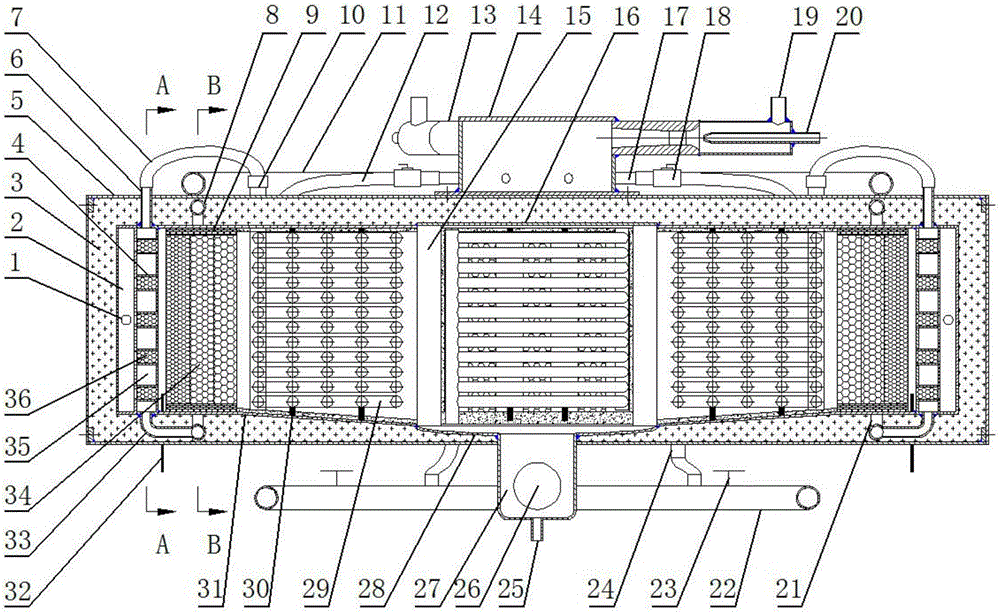

[0045] The structure and shape of the gas boiler based on porous media combustion technology in this embodiment are shown in Figure 1-4 .

[0046] The gas boiler based on porous media combustion technology in this embodiment includes a premixer, a number of combustion heat exchange units and a connection box; the number of combustion heat exchange units are connected through the connection box, and the combustion heat exchange unit surrounds the connection box The body is symmetrically distributed in the center, and the connecting box and the combustion heat exchange unit are wrapped with a shell 5, and the insulation material 3 is filled between the shell 5 and the connecting box and the combustion heat exchange unit to prevent heat loss. The premixer is set at Connect the upper part of the box;

[0047] The combustion heat exchange unit includes an anti-backfire structure, a combustion chamber 40, a tail heat exchanger and an air intake chamber 2, and two premixed gas inle...

Embodiment 2

[0057] In this embodiment, the structural connections of the various parts of the gas boiler based on the porous media combustion technology are the same as in Embodiment 1, except that the premixer includes a gas nozzle 20, an injector 13, an air nozzle 19, a premix chamber 14 and a premixer. Mixed gas outlet pipe 17; the bottom of the premix chamber 14 is fixedly connected to the upper surface of the connecting box, and two injectors 13 are arranged on the side near the top of the premix chamber 14, between the two injectors 13 The included angle is 120°, and eight premixed gas outlet pipes 17 are evenly arranged on the side of the premixed chamber 14 near the bottom, and the premixed gas outlet pipes 17 are connected with the premixed gas in the intake chamber The inlet pipe 1 is connected, and each premixed gas connecting pipe 12 is equipped with a stop valve 18, which is convenient for adjusting the working load of the gas boiler based on the porous media combustion techno...

Embodiment 3

[0059] The structural connection of each part of the gas boiler based on the porous medium combustion technology in this embodiment is the same as that in Embodiment 1, the difference is that the gas boiler based on the porous medium combustion technology in this embodiment has 6 combustion heat exchange units, Figure 5 It is a top view cross-sectional schematic diagram of the connecting box. The cross-section in the figure shows the side plates 15 connecting the box. There are 6 side plates in total, and each side plate 15 is connected to every two combustion heat exchange units.

[0060] In the gas boiler based on the porous medium combustion technology of the present invention, the raw materials, parts and installation methods involved are all well known in the technical field.

[0061] What is not mentioned in the present invention is applicable to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com