A full armor mud discharge pipe and its production method

A technology of mud discharge pipe and armor, applied in the field of full armor mud discharge pipe, can solve the problems of loss of fastening function of multi-layer steel fastening layer, technical defects of reliability of use quality, matching of difficult metal composite mud discharge pipe, etc. Achieve the effect of expanding the applicable field and scope of use, reliable pipeline direction adjustment technology, and highlighting substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

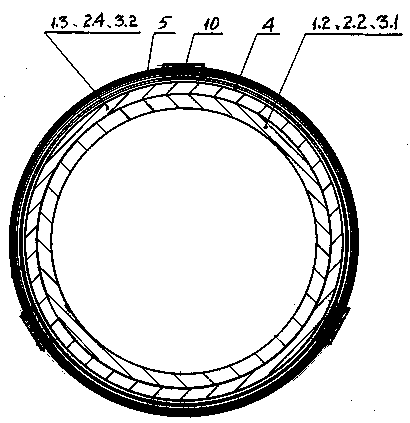

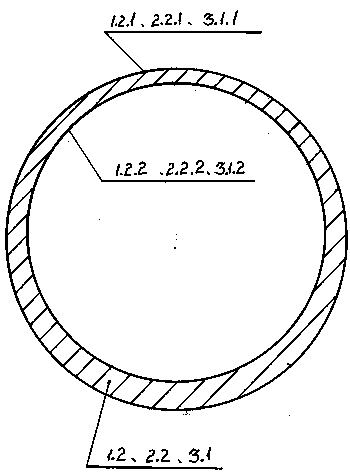

[0037] A kind of full armor mud discharge pipe of embodiment 1 of the present invention (referring to figure 1 , figure 2 ), including a pipe body and a connecting fastening layer, the pipe body is an inlet end pipe 1 with a flange, 5 tapered pipes 2, and an outlet end pipe 3 with a flange in order to be assembled as a whole . The inlet end connecting pipe 1 is a combination of the inner steel pipe 1.2 and the outer layer steel pipe 1.3, an inlet end connecting pipe flange 1.1 is provided at the inlet end, and two inlet end connecting pipes 1 are arranged on the outer side of the outer layer steel pipe 1.3. The annular positioning fastening ring 1.4, the outlet end of the inlet pipe 1 is provided with a tapered boss 1.5 of the inlet pipe 1 inserted into the inner chamber 2.1 of the inlet end of the tapered pipe 2, and the inlet pipe flange 1.1 is connected to the outer Several support plates 1.6 for the inlet end pipes are provided between the outer walls of the steel pipes...

Embodiment 2

[0048] A kind of full armor mud discharge pipe of embodiment 2 of the present invention (referring to image 3 , Figure 4 , Figure 5 ), including a pipe body and a connecting fastening layer, the pipe body is an inlet end pipe 1 with a flange, 8 tapered pipes 2, and an outlet end pipe 3 with a flange, which are armored and assembled in sequence . The inlet end connecting pipe 1 is a combination of the inner steel pipe 1.2 and the outer layer steel pipe 1.3, an inlet end connecting pipe flange 1.1 is provided at the inlet end, and two inlet end connecting pipes 1 are arranged on the outer side of the outer layer steel pipe 1.3. The annular positioning fastening ring 1.4, the outlet end of the inlet pipe 1 is provided with a tapered boss 1.5 of the inlet pipe 1 inserted into the inner chamber 2.1 of the inlet end of the tapered pipe 2, and the inlet pipe flange 1.1 is connected to the outer Several support plates 1.6 for the inlet end pipes are provided between the outer wa...

Embodiment 3

[0059] A kind of full armor mud discharge pipe of embodiment 3 of the present invention (referring to image 3 , Figure 4 , Figure 5 , Figure 6 ), including the pipe body and the connecting fastening layer compounded on the outside of the pipe body, the pipe body is an inlet end pipe 1 with a flange, 10 tapered pipes 2, and an outlet end with a flange The connecting pipe 3 is assembled into one piece of armor sequentially. The inlet connecting pipe 1 and the outlet connecting pipe 3 are composed of inner steel pipes 1.2, 3.1 and outer steel pipes 1.3, 3.2. The inner steel pipes 1.2 and 3.1 are wear-resistant layers. The wear-resistant high-chromium cast iron pipe is prepared by grinding the steel plate through the process of batching, blanking, pressing and welding. The outer steel pipe 1.3 and 3.2 are the reinforcement layer, and the ordinary spiral low-carbon steel pipe coil is used. The inlet end connection pipe 1 is composed of an inner steel pipe 1.2 and an outer laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com