Hydraulic pump valve integrated system of engineering machine

A technology for construction machinery and hydraulic pumps, used in mechanical equipment, rotary piston machinery, pumps, etc., can solve the problems of high process and installation, many connection points, and scattered structures, so as to reduce production costs, reduce quality, and reduce work. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

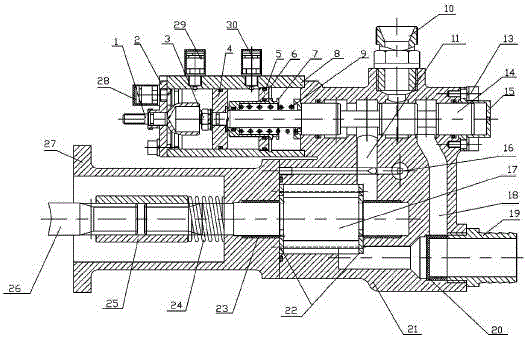

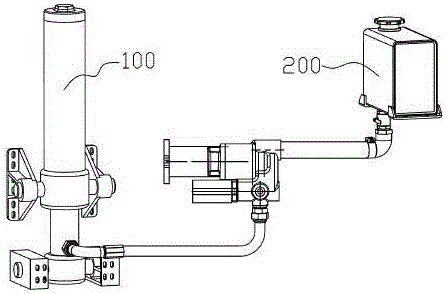

[0019] a kind of like figure 1 The overall hydraulic pump and valve system for construction machinery shown includes a pump valve rear body 21 integrally casted with a gear pump and a reversing valve body. The reversing valve body of the pump valve rear body 21 is connected with The cylinder block 8 has a mandrel 14 that can slide through the inside of the two, and is arranged in a dynamic seal with the mandrel 14 near the position adjacent to the cylinder body 8 and the rear body 21 of the pump valve; The oil inlet and outlet 19 is provided on the body 21, and the oil inlet and outlet 19 are connected to the reversing valve body through the oil return passage 18, and the oil inlet and outlet 19 are connected to the reversing valve body through the built-in oil inlet passage 11 through the gear pump at the same time. The valve body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com