Hydrogen sulfide automatic treatment device for oil and gas wells

An automatic treatment, hydrogen sulfide technology, applied in wellbore/well components, production fluids, earth-moving drilling and other directions, can solve the problems of accelerated pipeline corrosion rate, large equipment investment, and difficult operation, etc., to solve the problem of hydrogen sulfide corrosion, The effect of low power consumption and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

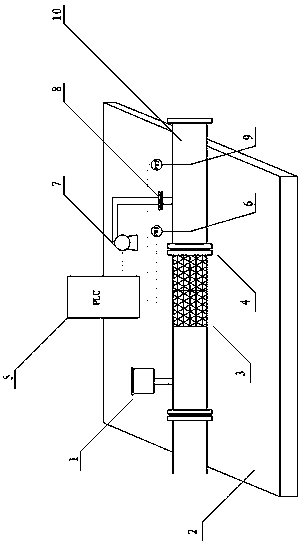

[0017] The invention provides a field treatment device for hydrogen sulfide removal of oil and gas well output, such as figure 1 As shown, it includes the base 2 of the dehydrogen sulfide mine processing device, and also includes a static mixer 3 arranged on the base 2, and an oxidant inlet 1 arranged on the static mixer 3, and an oxidizer inlet 1 1. The bottom is connected to the static mixer 3 by welding; the hydrogen sulfide removal field treatment device also includes a reduction pipeline 10 arranged on the base 2 and connected to the static mixer 3 by flange or welding, and the static mixing Both the device 3 and the reduction pipeline 10 are placed on the base 2 through pipeline support piers; the reduction pipeline 10 includes a first pH sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com