A microscopic visual displacement simulation system and its application method

A displacement simulation and driving system technology, applied in earthwork drilling, wellbore/well components, production fluid, etc., can solve the problem of inability to clearly observe the microscopic model, inability to achieve continuous and constant pressure, and inability to realize multiple displacements Replacement and other problems to achieve the effect of saving manpower and time, achieving heat preservation effect, and avoiding complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

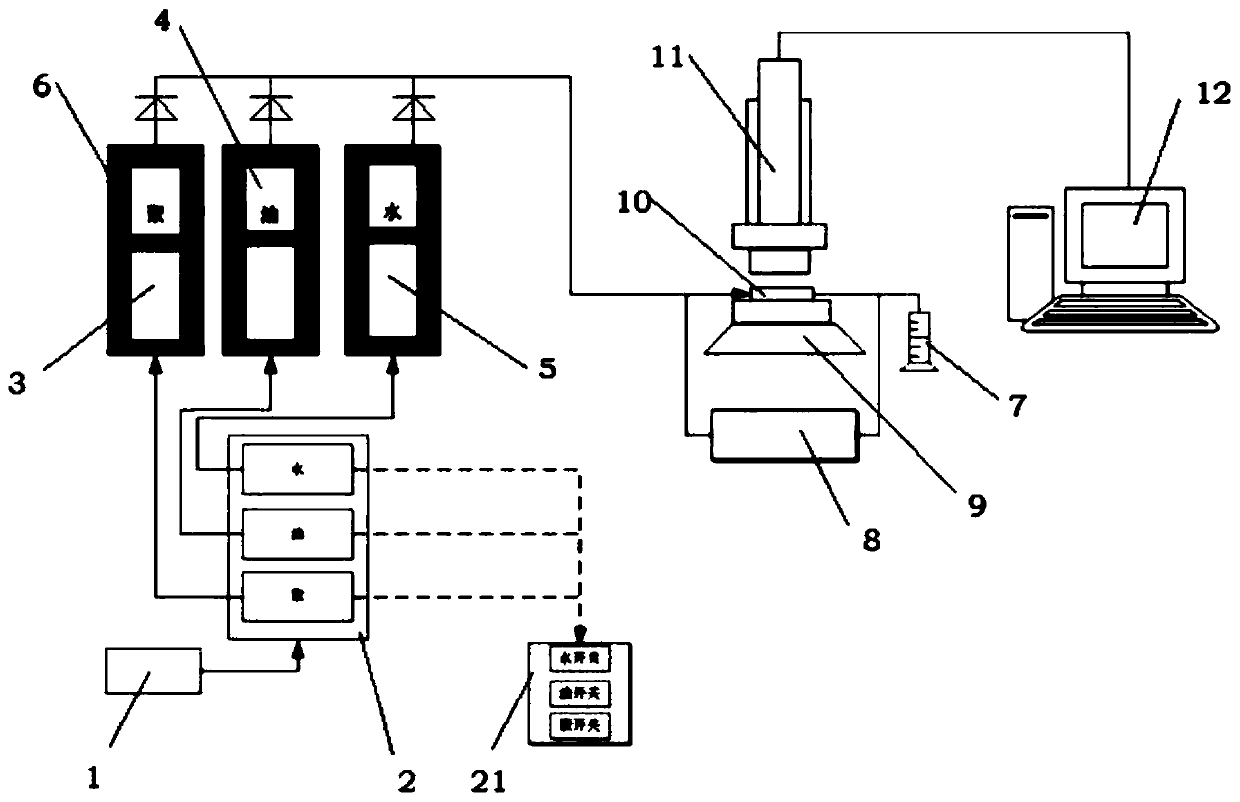

[0031] The invention mainly includes a high-resolution observation and acquisition system and a drive system;

[0032] The high-resolution observation and acquisition system includes a microscope magnification system 11, a dynamic capture system, an illumination system, a stage system 9 and an image acquisition and processing system:

[0033] (1) Microscope magnification system

[0034] Microscope magnification system 11 includes a microscope and a zoom control panel. In the process of experimental observation and collection, it is necessary to use the magnification and collection function of the microscope to observe the characteristics of the tiny fluid. The present invention uses a 230-fold microscope and adds a 100-fold lens for observati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com