Seamless preformed integral polyurethane floor

A polyurethane, integral technology, applied in floors, building components, buildings, etc., can solve the problems of manpower, material resources, slow construction speed, poor waterproof performance, etc., to improve waterproof performance, shorten construction period, and overcome long construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

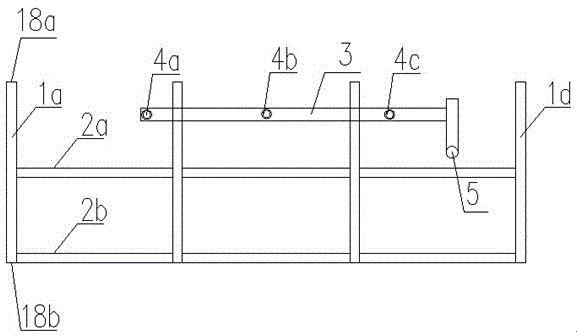

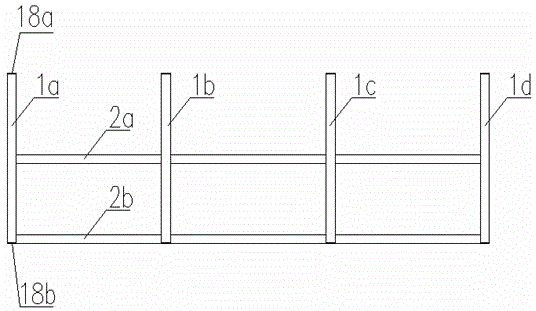

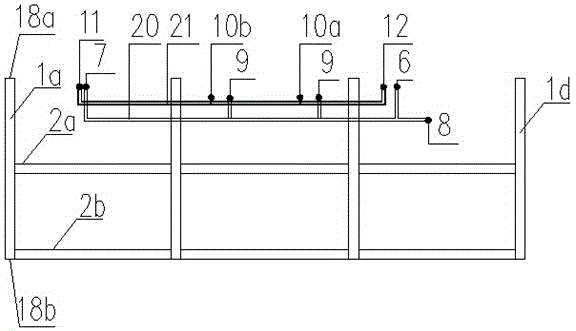

[0023] Such as figure 1 As shown, four main beams 1 (1a, 1b, 1c, 1d) and six secondary beams 2 (2a, 2b) are manufactured in the factory, the main beams 1 and secondary beams 2 are made of laminated lumber, and the layer The building timber is a heavy wood structure composed of wood squares stacked orthogonally and glued together. Four main beams 1 and six secondary beams 2 are tightly connected by metal connectors 18 (18a, 18b), and pre-installed at the end of each main beam Metal connector 18. Such as figure 2 As shown, the sewage pipe 3 is installed on the structural frame, the floor drain 4 (4a, 4b, 4c) is pre-installed on the upper part of the pipe, the sewage pipe 5 is installed at the position of the toilet, and the sewage pipe 5 is fixed on the frame beam, and at the same time Make the sewage pipe 5 maintain a slope of 1%.

[0024] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com