Hydraulic drive spin type trash drift

A hydraulic-driven, spin-type technology, applied in water conservancy projects, cleaning of open water surfaces, construction, etc., can solve the problems of difficult work on the river surface, the lack of self-cleaning ability of pollution blocking and drifting, and time-consuming and labor-intensive problems. Convenient to salvage dirt, convenient salvage operation, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

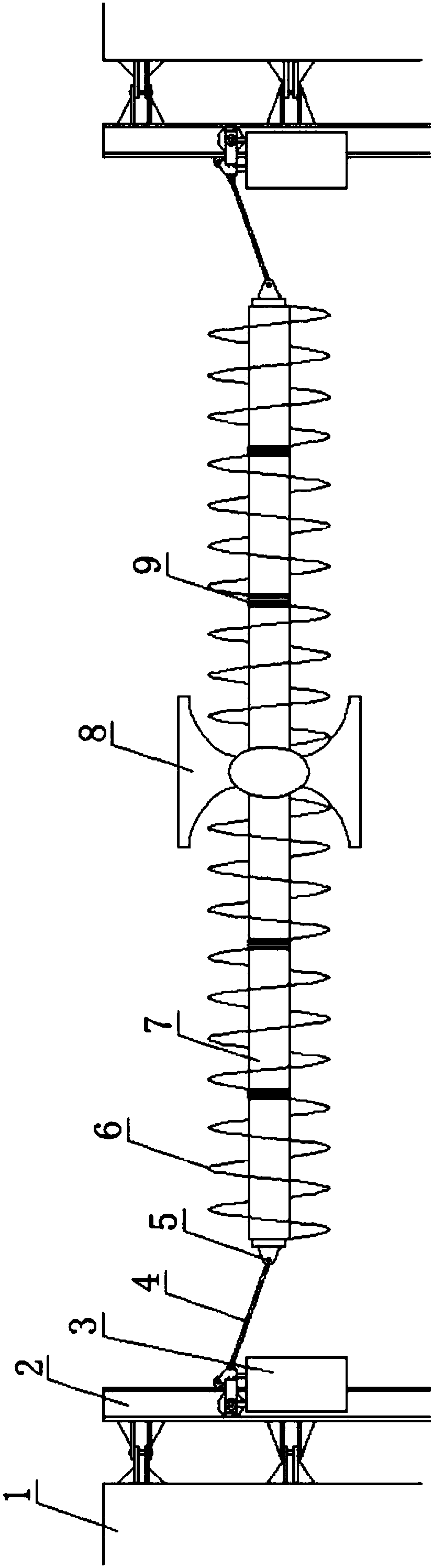

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A hydraulically driven spin-type trash-retaining float includes a dam 1, vertical rails 2 are relatively fixed on the inner parts of the dam 1 on opposite sides, and installation buoys that can move up and down on the vertical rails 2 on the opposite sides respectively. The box assembly 3 is rotatably installed on the two opposite bearing seat assemblies 5, and the hollow seal shaft assembly 7 is installed, and the water impeller assembly 8 is fixed on the hollow seal shaft assembly 7. On the shaft assembly 7, the auger blades 6 with opposite helical directions are respectively fixed on the two sides of the water impeller assembly 8. The stay cables 4 on both sides hang and connect the hollow sealed shaft assembly 7 to the pontoon assemblies 3 on opposite sides. The hollow sealing shaft assembly 7 is composed of a plurality of hollow sealing shafts sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com