Intelligent piston ring electrochromism system

A technology of piston rings and electrochrome plating, applied in electrolysis process, electrolysis components, cells, etc., can solve problems affecting the health of workers, heavy labor, manual work, etc., to reduce the cost of manual inspection and maintenance, automation and intelligence The effect of high degree of automation and reduction of labor costs for enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

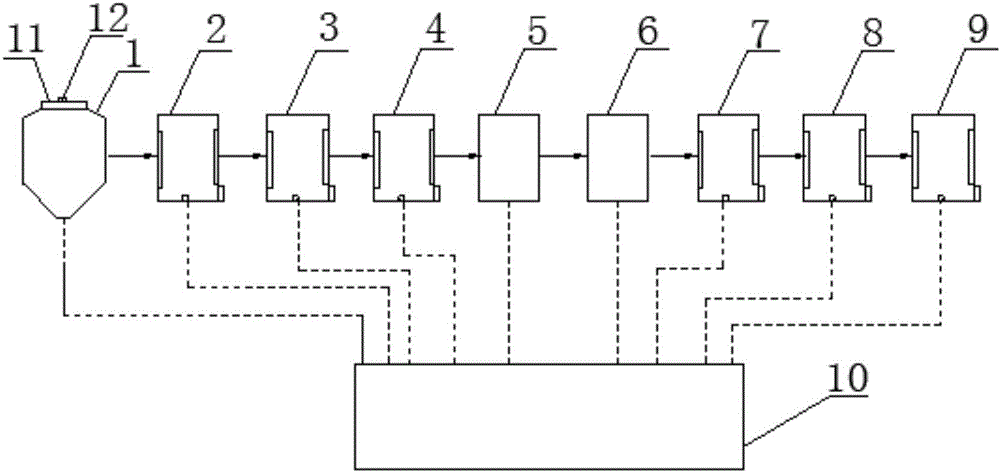

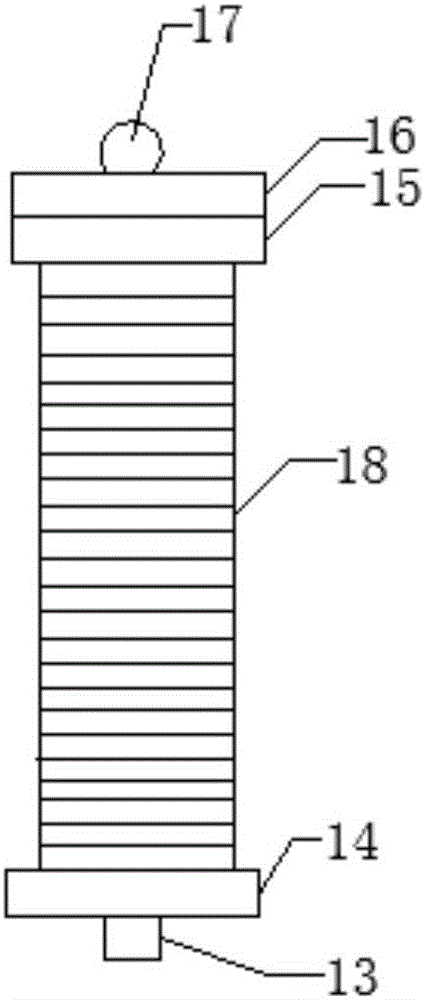

[0021] Embodiment: a kind of intelligent piston ring electrochrome plating system, such as figure 1 and figure 2 As shown, an intelligent piston ring chrome plating system is provided, including sandblasting machine 1, pickling device 2, first water washing device 3, second water washing device 4, etching tank 5, chrome plating unit, Alkali washing device 7, the third washing device 8 and the fourth washing device 9, each of the above-mentioned parts is provided with a sub-control system; a plurality of piston rings 18 are clamped into a barrel shape by a clamp; a driving device and a main control system 10 are also provided , the sub-control systems are all connected with the main control system 10, and the barrel-shaped piston ring 16 clamped by the clamp is suspended from the driving device, the main control system 10 is electrically connected with the driving device and controlled by The operation of the traveling gear controls the time that the piston ring 16 dwells in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com