Sanding tank for production of composite electroplated diamond wires and utilization method of sanding tank

A diamond wire and composite electroplating technology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problems of poor wire diameter uniformity of finished wires, insufficient structure design of the upper sand tank, and poor distribution of diamond micro-powders, etc. The effect of controllable sand application rate, improved efficiency and coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

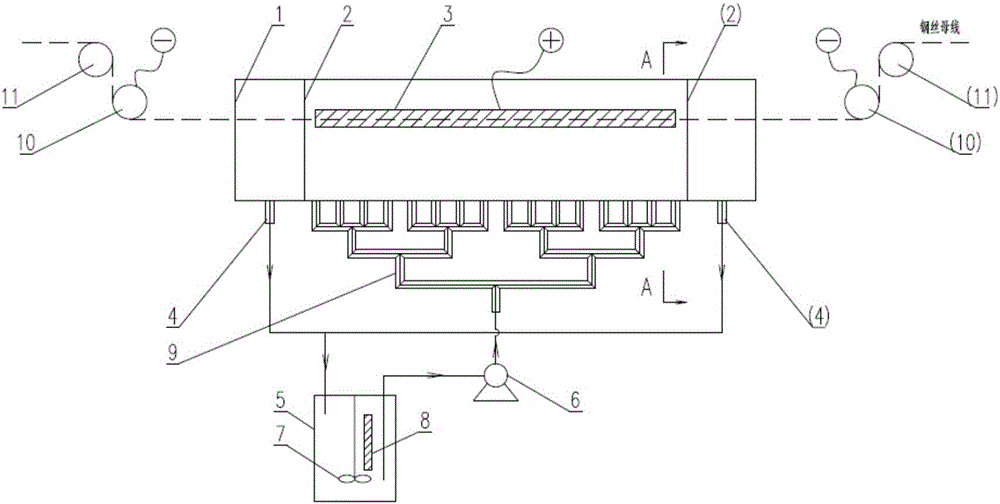

[0028] figure 1 Among them, an upper sand tank for producing a composite electroplating diamond wire, including an upper sand tank body, an inlet liquid circulation device, an inlet liquid distribution device, a steel wire transmission device, and the like.

[0029] The upper sand tank body 1 includes three areas, the middle area is the upper sand area, the two side areas are overflow areas, and the middle partition of the three areas is equipped with a liquid level adjustment plate 2; the lower part of the overflow area of the upper sand tank body There is a return pipe 4;

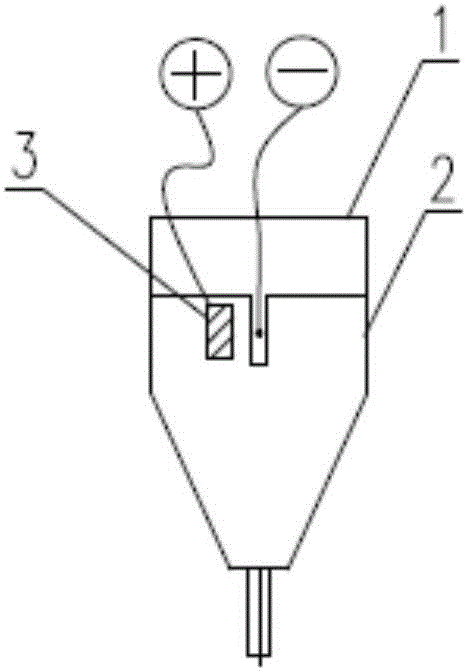

[0030] figure 2 Among them, the cross section of the lower part of the upper sand area is a lower narrow trapezoid; one side of the upper sand area of the upper sand tank body is equipped with a titanium basket 3, and nickel balls are housed in the titanium basket. Anode; the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com