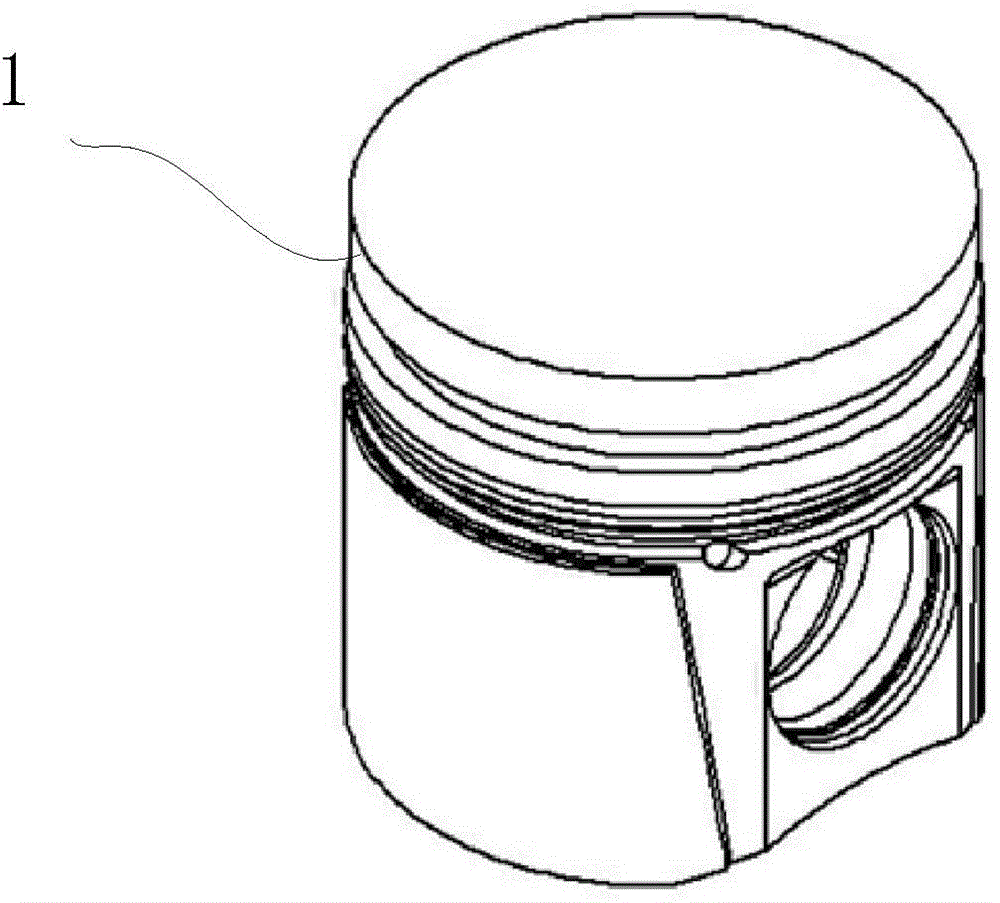

Piston top surface thermal fatigue-resistance alloy coating laser cladding method

A technology of laser cladding and thermal fatigue resistance, which is applied in the coating process and coating of metal materials, can solve the problems such as difficulty in obtaining a uniform and stable cladding layer, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An embodiment of the present invention provides a laser cladding method for a thermal fatigue-resistant alloy coating on the top surface of a piston, comprising the following steps:

[0029] Step 1: Perform machining pretreatment on the top surface of the piston blank; according to the set thickness of the cladding layer, cut the top surface of the piston blank to remove the oxide layer and expose the base material of the piston blank, so that the thickness of the piston after cutting The dimensional difference from the thickness of the finished piston is the set cladding layer thickness, and the error is ≤0.5mm.

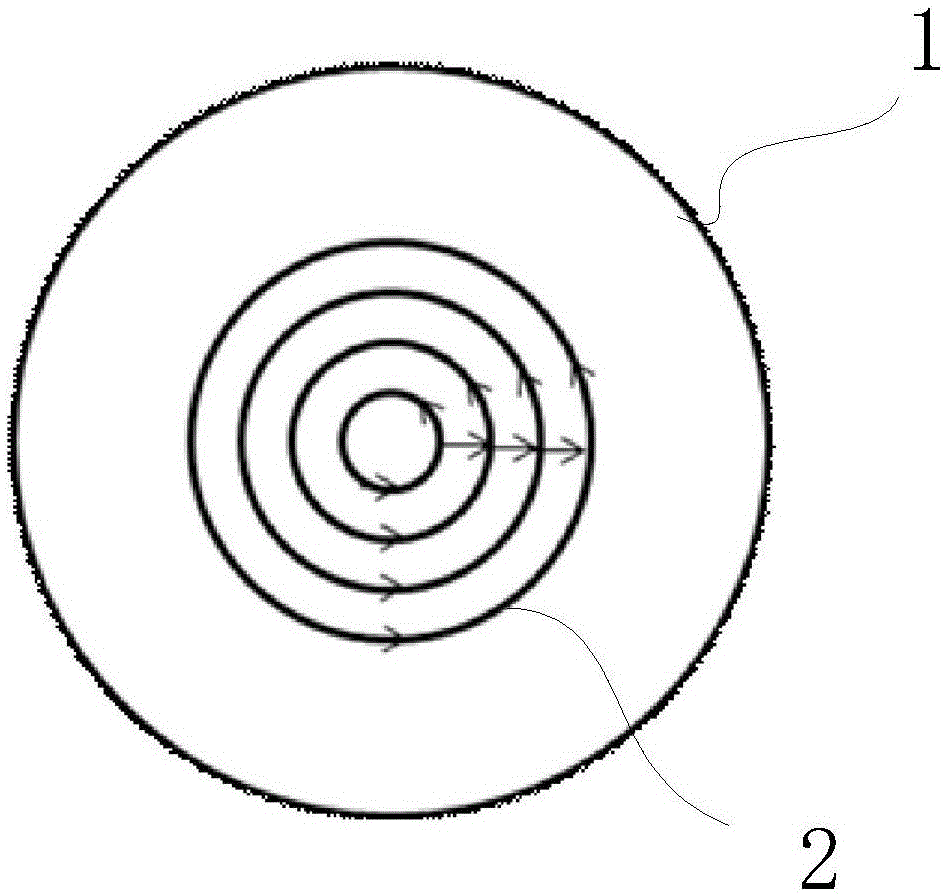

[0030] Step 2, set the laser trajectory according to the structure of the top surface of the piston;

[0031] The trajectory of the laser can be set according to the shape, size and thickness of the cladding layer on the top surface of the piston, and multiple multi-layer concentric circles or circles with multiple multi-layer centers on the same axis can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com