Method for enriching platinum group metal from invalid automobile exhaust catalyst metal carriers

A technology of catalyst metals and platinum group metals, which is applied in the direction of improving process efficiency, etc., to achieve the effects of simple operation, high platinum yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

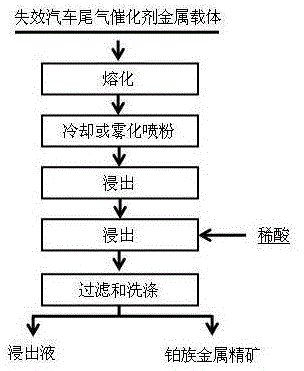

[0026] See attached figure 1 , Conditions: 1000g of exhaust gas catalysts with metal carriers, smelted in a plasma furnace, atomized and sprayed to form fine powders containing platinum group metals; base metals were leached with sulfuric acid, the dosage was 60% of the weight ratio of the alloy matte phase, and the temperature was 55 ℃, the time is 4h, the liquid-solid ratio is 5:1, the enrichment of platinum group metals reaches 25 times, and the yield is 98.67%.

Embodiment 2

[0028] See attached figure 1 , Conditions: 3000g of exhaust gas catalysts with metal carriers, smelted in a high-frequency furnace, cooled with water, crushed to form fine powders containing platinum-group metals; base metals were leached with sulfuric acid, the dosage was 80% of the weight ratio of the alloy matte phase, and the temperature was 85°C for 4 hours, the liquid-solid ratio was 5:1, the enrichment of platinum group metals reached 30 times, and the yield was 99.10%.

Embodiment 3

[0030] See attached figure 1 , Conditions: 5000g of exhaust gas catalyst on metal carrier, smelted in a high-frequency furnace, atomized and sprayed to form a fine powder containing platinum group metals; leached with hydrochloric acid, the dosage is 50% of the weight ratio of the alloy matte phase, and the temperature is 65°C , the time is 5h, the liquid-solid ratio is 3:1, the enrichment of platinum group metals reaches 24 times, and the yield is 98.67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com